adv.: Supplier of Copper Anodes, Nickel Anodes, Bismuth Metal, & Other Metal Products for Industry & The Arts

• Topic #2681 "How to remove Zinc contamination from Nickel plating bath"

• Topic #3778 "Problems in Nickel (& nickel-chrome) plating on Zinc Diecastings"

• Topic #31166 "Allowable metallic contamination in nickel plating bath"

• or continue here on ... -----

"Dummying" an electroplating bath?

Q. Hello, guys!

I'm a chemical engineer who has been working with electroplating for the last two years. I work with zinc die casts in nickel baths, so I've had to do dummy plating a few times by now.

I do understand the basics of how to plate out: the corrugated metal sheet, the agitation of the bath, the LCD etc etc.

But even though I'm an avid researcher, I can't seem to find the reason WHY IT WORKS.

I've tried an approach through the reactivity and electrochemical series. I realized zinc is more reactive than nickel and plates out. However, copper also plates out, but is less reactive than nickel. So, my guess is that it has nothing to do with the reactivity, the electrode potential or the overpotential of the cell.

One thing that also always makes me scratch my head is why is it recommended to lower the pH of the bath? I've successfully plated out zinc in the operating pH and don't understand this recommendation.

Another thing is that here in Brazil it is common to use an organic additive that we call "purifier", which helps hiding zinc contamination. I've never read about this additive here in finishing.com. Do you guys know how this additive work?

I know I asked three questions in the same topic, but I have the impression that the answers are related.

Ted usually asks us to describe the problem we are facing in the plating line, but my only problem right now is an unquenchable curiosity. :D

Regards,

- Nova Friburgo, Rio de Janeiro, Brasil

October 18, 2022

⇩ Related postings, oldest first ⇩

Q. Hello, I am Vu.

I am not sure about the meaning of dummy plating.

- they usually apply the dummy plating after make up a new electroplating bath. What for?

- they apply the dummy when has some of the impurity of another metal in bath.

Could you please explain more details of the dummy plating? Working condition? How is the cathode? etc.

Thank you very much for your help.

- HCM city, Vietnam

October 30, 2009

A. Hello, Cousin Vu. Dummy plating is one of several ways to deal with contaminants in a plating bath. It is usually used against metallic impurities, especially if the contaminant is more noble than the main metal of the plating bath. For example, copper contamination in a nickel plating bath.

In theory, you simply plate at a low voltage onto scrap cathodes, in hopes that the contaminant metal will plate out preferentially, so you will plate out the contaminant onto the scrap, without plating out too much of contents of the plating bath.

In practice, the dummy cathode is often a sheet of corrugated metal. In the old days, nickel plating tanks often had dummy plating compartments, so that you were continuously plating out copper and other contaminants. These days dummy plating is usually a periodic batch type operation instead. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear Ted,

Thank you for your explanation.

I've just come to customer and service them to make up the copper pyrophosphate plating. After the make up, they plate the dummy with grille cylinder as cathode.

So could you please let me know what did they plate the dummy after make up for?

Beside that, I worry about the grille cathode for dummy plating. This is the Japanese style and is not the same with my experience.

best regards,

Ha Uy Vu

- HCM city, Vietnam

A. Hi, Vu. I don't know what a grille cylinder is, but what is used as the dummy cathode may not matter. I do not know why it is suggested to dummy a brand new copper pyrophosphate bath. If this is a proprietary bath there should be a technical data sheet for it that describes whether or not it requires dummying. If it is a "home brew" bath, perhaps the copper pyrophosphate is not pure enough.

I would suggest plating Hull Cell ⇦ huh? panels and seeing if they look good without dummying.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 31, 2009

Q. Hello,

Is it advisable to do dummy plating in barrel plating operation. I heard that for dummy plating operation air agitation is must. In barrel plating operation during that dummy plating there won't be any air agitation in the bath. Will this be effective. Will it contaminate the bath instead of purifying.

Does this dummy plating operation remove iron impurities from the bath.

Please clarify?

Electroplating - India

January 17, 2011

A. Hi Neelakandan.

You did not mention what kind of plating you are doing, so it is hard to answer your question. But in acid zinc plating it is usual to add peroxide to precipitate the iron, and filter it out rather than dummying. If that is your situation please see our library article "Improving Your Chloride Zinc Plating Operation". Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. HELLO,

SIR, HOW CAN I REMOVE COPPER IN THE NICKEL SOLUTION. I HAVE SOME COPPER IN MY NICKEL SOLUTION.

- Pakistan

February 24, 2012

Q. Sir,

What type of Dummying is preferred for continuous nickel plating process? Stainless steel or Mild steel with corrugated sheet?

Please suggest with this regard.

power systems - Hyderabad, Andhra Pradesh, India

December 21, 2013

A. Hi Sastry. Plain steel corrugated roofing sheets ought to be fine. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Sir,

Dummy current is 5 amps/SFT of the dummy size.

Is it correct or not? How much current is applied for the one SFT?

Awaiting for your reply.

Regards

- Hyderabad, Andhrapradesh, India

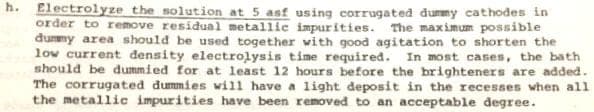

A. Hi Sastry. Yes, 5 ASF (amps per square foot) ought to be okay. Please see brief excerpt from the nickel plating chapter of "Electroplating Course Manual - Basic Practical Electroplating" published by the Garden State Branch of American Electroplaters' and Finishers' Society Inc., edited by F.J. LaManna

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Nickel platers - do you dummy your tanks?

Q. This seems to be hotly contested. I'm a believer in dummying. Here's why:

Faraday's Law of Electrolysis applies to the anode as well as the cathode. There are going to be HCD areas on the crowns, or whatever, where the primary reaction becomes oxide formation rather than Ni dissolution. These oxide coated areas are apt to serve as sites for brightener oxidation. This introduces undesirable contaminants that aren't readily removed by carbon filtration because they are charged anions. I think they're removed so some extent by LCD electrolysis.

Another thing that might work is treatment with an anionic ion exchange resin. I once had some luck with this in the lab but never tried it on an actual bath.

Dave Wichern

Consultant - The Bronx, New York

October 31, 2015

A. Some dummy regularly and some run forever without ever dummying.

IMO dummying is necessary only if contaminants (primarily lead, zinc and copper) are present, or if anode and cathode densities are unreasonable.

However there was at one time a well known supplier who sold a self-contaminating nickel brightener.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

A. Good day Dave.

I think dummying requirements are directly proportional to good housekeeping and proper process control.

That is a very interesting explanation regarding the oxide formation on HCD areas of the anode producing brightener oxidation. I would think the anode/cathode ratio is at play here regarding HCD oxidation. I would also think the anode ratio is too small, as it is producing HCD oxides.

I must agree with Jeffrey regarding metallics. Dependent on the substrate, one will get contamination depending on load size and ASF. Parts do fall in the solution, and as you well know, they are not always discovered/removed.

They will dissolve in solution and cause shelf roughness issues = dummying.

Proprietary brighteners/additives can address copper contamination in LCD areas as darkness.

A brightener overload will cause LCD problems/darkness/poor throw/coverage = dummying.

Just thought I might throw in my two cents.

Regards,

Aerotek Mfg. Ltd. - Whitby, Ont., Canada

A. High current density dummying removes sulfur from the bath. So if your Ni deposits are compressively stressed, high CD dummying will make them less compressive and eventually tensile.

Only drawback is that high CD dummying is expensive.

Pat Mentone

St Paul, Minnesota

Q. I would like to know if anyone thinks you can dummy plate Zinc contamination out of a hex chrome plating solution. I would like to try it on Nickel plated corrugated steel. Maybe? High or low current density and any suggestions most appreciated.

Rich Mancinelli- Newnan, Georgia USA

May 13, 2016

A. Rich,

I never heard dummy chrome to take out zinc contamination, but you can decant chrome solution to cut contamination out.

Make sure LCD dummy does not create trivalent chrome problem ; once you create trivalent chrome you cannot chrome plate on the part.

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

A. Doubt you'll have much luck dummying out Zn.

Try a porous pot purifier.

Dave Wichern

Consultant - The Bronx, New York

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. Why dummy should be in zig zag shape? At what current density do we have to run it. Low current or high current density?

Ragul Rajendranplating shop employee - coimbatore,tamilnadu, India

October 15, 2016

A. Hi Ragul. The zig zag shape is preferred both because it offers a bit of range in current density, and because it offers more surface area than a flat sheet. Why it might be done at high current density was explained by Pat Mentone. But as others have said, it's usually low current density, about 5 ASF or lower. But you haven't yet told us what kind of plating you are doing nor what kind of contaminants you are trying to remove, so it's hard to expand upon the information already offered. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. In many cases a current density of only 3 ASF is used and the current density is calculated on the projected area of the zig-zag plate (as if it was a flat sheet) not the actual area.

Lyle Kirmanconsultant - Cleveland Heights, Ohio

A. You dummy a chromium bath to activate the anodes and reduce trivalent chromium.

If you are using dummying to remove impurities at low CD often best to do a Hull Cell first and see if there is a dark band and then estimate the CD that that band is and then "dummy' at that average CD. Don't use too sharply corrugated sheets as you will waste too much metal on the high CD areas, and not get at enough at the targeted CD.

In the case of nickel always plate at normal CD first to get a coherent coat before lowering to the dummy CD so you get a coherent coat first as often the contaminated coating is porous and non adherent.

Don't dummy continuously unless you know you have a need, as you will just waste metal and power.

There are many other alternatives to "DUMMYING'

Geoffrey Whitelaw

- Port Melbourne, Australia

Q. How do you dummy an electroless nickel bath after a new make up?

I am plating nickel on ceramic capacitors and the first loads usually fail and I get black parts. After a few runs, then I get good results.

Thanks

Reynaldo

- Sylmar, California, USA

November 8, 2016

A. Not only electroplating baths, electroless plating such as electroless copper, electroless nickel also need dummying during re start-up after bath idle for certain time to consume excess stabilizer and activate the metal ions reduction reaction to prevent skip plating in following production.

David Shiu

- Singapore

A. By the term dummying it generally indicate LCD (Low Current Density) plating for Nickel as Zn and Cu are the most common impurities and can be deposited at Low current. While for Chrome it is done at high voltage and still call as dummying. So we can say that 'plating out' impurities from the main bath can be termed as dummying.

Regards,

T.K. Mohan

plating process supplier - Mumbai, India

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. How can I remove the impurities such as copper & iron from an acidic zinc electroplating?

mark smith- warsaw, poland

December 3, 2017

A. Hi cousin Mark. There is no "such as" in this situation ... there are only specific suggestions for specific impurities in specific baths :-)

This thread started with a discussion about using dummying to remove copper from acid zinc, and in an earlier response I suggested adding hydrogen peroxide to acid zinc to precipitate the iron and make it filterable. There may be other approaches if you have a problem with these suggestions. Good luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Dummying Nickel Contamination from Copper Cyanide Bath

Q. Hey everyone I have a question about "dummying".

I have a high nickel contamination in both copper cyanide strike and plate at 128 ppm and 341 ppm respectively. Also my Fe is high around 150 ppm in both baths. I have taken over this plating line less than a month ago so this was present before I started.

I know that Fe will not readily plate out, but can nickel be plated out at LCD say 3-5 A/sqft? A carbon/peroxide treatment would help the nickel but don't believe the Fe will go anywhere unless I cut the bath or make it up new. Is there anything else I'm missing here that I can do?

Any answers are welcome, thanks!

Plating Supervisor - Chicago, Illinois, USA

April 5, 2018

A. Hello Brian, nickel nor iron will co-deposit with copper. Are you experiencing poor throwing power? My suggestion would be to decant the bath, add back the bath constitutes.

Mark BakerProcess Engineering - Phoenix, Arizona USA

Q. Yes I am getting pretty poor throw in the cyanide plate with a dark deposit in the LCD and more of a darker red copper. Adding brightener has negative affects in the Hull Cell.

The strike however is still running like a champ.

So you're suggesting letting the solids settle over the weekend, pump off the top liquid, and waste treat the bottom couple hundred gallons that are left in the tank?

[returning] - Chicago, Illinois, USA

A. Hello Brian, I apologize for the delay on your second question. What I have had to do in the past is to figure the percentage you want to decrease the concentration of Ni and Fe contamination. Let's say it's a 20% desired reduction. You would pump out 20% of the solution and waste treat it. The amount of solution that is pumped out must be replaced. Refer to your tech data sheet for the amount of each chemical to add back to the bath plus water of course. I don't think the Ni or Fe will settle to the bottom of the tank overnight without using a precipitator, which I am not aware of any.

Mark BakerProcess Engineering - Phoenix, Arizona USA

Q. Hi,

we would like to plate out Nickel, Iron and Zinc contaminants in our pure tin plating bath. Any suggestion on how to do this? if we opt to use Hull Cell first, what could we use as anode/cathode material?

- Manila, Philippines

October 19, 2018

A. Hi Anton. Ideally, a corrugated sheet is used for dummying because it offers more surface area than a flat sheet (π/2 x as much if the corrugation is a true sine wave), as well as various current densities. In a Hull Cell you already have a great range of current density so the corrugation probably isn't important.

You haven't told us yet whether the tin plating bath is MSA, stannate or what, but ... do you have reason to believe that all those contaminants are present, that they are responsible for whatever problems you are having, and that they can be dummied out of that type of bath? I tend to doubt that you can dummy zinc out.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Thanks Ted!

Our Tin plating Bath is MSA based, and the three metals are what we have measured using AAS

⇦ on

eBay

or

Amazon [affil link] . we would like to dummy-out these metals, rather than diluting our plating bath to reduce its ppm content.

If I were to use SS plate as cathode material in Hull Cell set-up, will I still need pure tin metal for the anode?

- Manila, Philippines

A. Hi again Anton. Although, it doesn't discuss those metallic impurities specifically, Charles Rosenstein's article "Methane Sulfonic Acid as an Electrolyte for Tin ..." does say that dummying can be done to reduce metallic impurities.

But a Hull Cell is used to predict what will happen in the actual process tank, and it doesn't seem constructive to me to employ a Hull Cell test in a manner which is unrepresentative, so I think you should use pure tin anodes in the Hull Cell. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread