-----

Restoring the yellow dichromate finish on automobile carburetors

Carburetors are made of diecast zinc with a chromate conversion coating ("Alodine" and "Iridite" are two common tradenames).

Aesthetic restoration is difficult for a number of reasons: zinc diecastings are a poor surface to begin with; if the 'skin' is damaged the porous body can be nearly impossible to deal with; there can be grain separation of the metal over the years; 'conversion coatings' are not something put on top of old metal, but are a reaction product involving that old passive metal.

The best path forward is usually considered to be to zinc plate the carburetor first, and then chromate conversion coat the fresh zinc rather than the aged diecasting.

Q. I am restoring vintage carbs and need to find out some info on restoring the finish. I am looking for dichromate in small quantities like 5 gallons. Any help would be appreciated.

Stewart Woodautomotive repair - Tulsa, Oklahoma

2005

Q. I wish to know the proper technique for dichromating automobile carburetors to their original factory appearance. Any help would be appreciated.

Lynn PalmerAuto restorations - Houston, Texas

2006

A. Hi, Stewart. Hi, Lynn. I think you'll find that reworked carburetors usually need to be zinc plated before they are chromated because, after years of environmental exposure it's very difficult to get the old diecast metal uniformly active so that it can generate a uniform chromate conversion coat, whereas a fresh coating of zinc can accept the chromate better. A local plating shop can do this chromate conversion coating for you, and the zinc plating if necessary, and that would be the easiest approach.

Otherwise you'll want to get hold of one of the "must have" books on electroplating to understand how to prep the parts, do the zinc plating on them, possibly bead blast, then do a chromate conversion coating process. We can't easily give step by step instructions because it's complicated, and the compounds you need like Alodine are dangerous and carcinogenic, disposal is difficult, and the metal preparation steps are difficult and more crucial than the chromating step. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. We are trying to restore the dichromate finish on some carburetors to like new condition. We are using a dry media in a tumbler that leaves no residue. Following the instructions to the letter from the kit that we bought, the carburetors dichromate finish comes out uneven with various shades throughout. What is the correct procedure to ensure that the dichromate finish is perfect giving the carburetor the appearance of being new in condition? If any additional info is needed, I will provide it. Thanks.

George David Patrickdichromating carburetors - Sylvania, Georgia

2005

A. Step 1. would be to ask the company that sold you the "kit".

That said, carbs are normally made from a casting which seems like it is as porous as a sponge. It is very difficult to get the soaked in gas and oils out of the metal any deeper than the surface. You might try this. Boil the unit for an hour in a solution of distilled water with enough bicarbonate of soda added to raise the pH to 8. This would be a couple of tablespoons per gallon or thereabouts. Add a few drops of baby shampoo or a commercial wetting agent like triton 100. Blow it dry and then put it in your tumbler with new media. When you chromate it, you will need a weak etch cleaner rather than a strong etch cleaner as it will remove a lot of the "clean" metal that you now have. What are you using for a deoxidizer/ desmutter?

- Navarre, Florida

Multiple threads merged: please forgive chronology errors and repetition 🙂

Historically correct clear and gold chromate finishes for carburetors

Q. We are reproducing carburetors which were first manufactured during the thirties. We are attempting to reproduce the original colour on the zinc (ZP5) die castings also. Materials used were: Nitric, Sulfuric, and Chromic acids which produced a pewter grey with slight gold overlay and pink/ blue/ green iridescence.

In the fifties this was changed to a gold dichromate with red/green iridescence. Are there modern equivalents of these which will create the correct appearance?

Ed Wimblecarburetor manufacture - London, England

2005

"Problem with chemical polishing zinc die castings"

Q. I have been recoloring old zinc small engine carbs (finish is gold/green chromate). I first had a company do some carb bodies for me and they were pretty much always consistent. They sent a Lab report the 2nd time I had them do some carbs for me.

The Lab report says the company did it a particular way, so I bought the chemicals and tried it exactly as the lab report says.

Bead blast casting with very fine beads 30-40 psi.

Soak in the caustic solution 8/oz to gallon distilled water.

Cold water rinse

Chemical polish: 50% by volume + distilled water 10-45 seconds, 120°-140°

Cold water rinse

Chromate finish: 2% by volume + distilled water 3-10 seconds, 75°

Cold water rinse

Hot water rinse 150° or less

Hot air dry 170° or less

It hardly ever works. So I experimented.

What I have found is that if I bead blast, soak in the caustic for only 2-3 seconds (just before the part starts to outgas) cold rinse. Then polish with SOS pad

⇦ on

eBay or

Amazon [affil link] , rinse, dip in the polishing for 1 second and right into the chromate for 4 seconds, it starts to look like what the company did.

If I leave the part in the caustic and let it outgas, it never takes.

If I leave it in the Chemical polish the required time, it starts turning the metal a dark gray and when rinsed and dipped in the chromate. it turns the part a really ugly brown/gold (which you can take off the brown "oxidation" under cold water just scrubbing with a rag)

I am just wondering if someone could shed some light on this problem here.

1) what exactly is the caustic soak supposed to do? Break the "skin" of the zinc and remove any oils that may or may not be in the pores of the metal?

2) Why does the chemical polish turn the part gray and is the gray not supposed to rinse off in the cold water rinse? I spent a lot of dough on these chemicals. I can spend 4 -5 hours on 3 or 4 carb bodies (each is the size of pack of playing cards stack 4 tall)

I KNOW that the company that did these did not spend more than 10 minutes to do all 4 that I sent and they were already beadblasted when they got them.

vintage m/c restorations - Wills Point, Texas

2007

A. I don't claim any knowledge about refinishing carburetors, but that caustic step must be wrong. ASTM B252 mentions a pH of 7-10 for soak cleaners for zinc die castings, which equates to a maximum of 0.05 ounce NaOH per gallon. The 'outgassing' is hydrogen from OH(-) attacking the zinc.

Given that the short chemical times work best, try eliminating those steps. Use the finest possible bead blast and then directly chromate.

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Need Chromate Dye for 67-72 Holley Carburetors

Q. Hello, my company deals in restoration of Ford Holley carburetors. I am looking for a chromate dye that we can apply to the completely disassembled and fully cleaned metal that will restore the original factory look. I can best describe the original finish as gold with a slight green hue. Thanks for your help.

George LanoueRestoration of vintage auto parts - San Jose, California, USA

May 29, 2008

Holley Carburetors & Parts on eBay (affil link)

A. Hi George.

It's not a dye, it's a "conversion coating". The reason I'm being a stickler on the semantics is that the chromating solution must react with the metal, and uniformly reacting with the inactive, non-uniform, old metal is a troublemaker. Please contact one of the major suppliers of chromate conversion chemistry and, with luck, you may be able to get acceptable chromating. If not, you'll have to do zinc plating first.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

? I was just wondering if you ever came up with a method for refinishing the Holley carb's Zinc Dichromate finish that works well?

Steve Hulett- Ocala, Florida, USA

June 13, 2013

Q. I am restoring some carburetors for classic cars. Some of the cast steel parts are finished with a translucent yellow and some with opaque black. How can one reproduce such finishes?

Thank you.

Bill ClarkHobbyist - San Antonio, Texas, USA

April 8, 2009

A. Hi, Bill. The translucent yellow on steel is probably zinc electroplating followed by a yellow chromate conversion coating. I am not familiar with those carburetors or their black coatings but it might be zinc plating followed by a black chromate conversion coating or the parts might be black oxided.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Thanks for the information. It turns out that some of the carburetor sections are steel or cast iron (the base) and some (the air horn and bowl) are a cast zinc alloy.

So, my questions are better asked like this:

1. How do I get the cast iron or steel to turn black?

2. How do I get the cast zinc alloy to turn yellow?

Many thanks,

Bill Clark [returning]Hobbyist - San Antonio, Texas, USA

A. I would suggest that you first have the components refinished by a metal finisher before you perform the mechanical restoration of the components.

Gene Packman- Great Neck, New York

Multiple threads merged: please forgive chronology errors and repetition 🙂

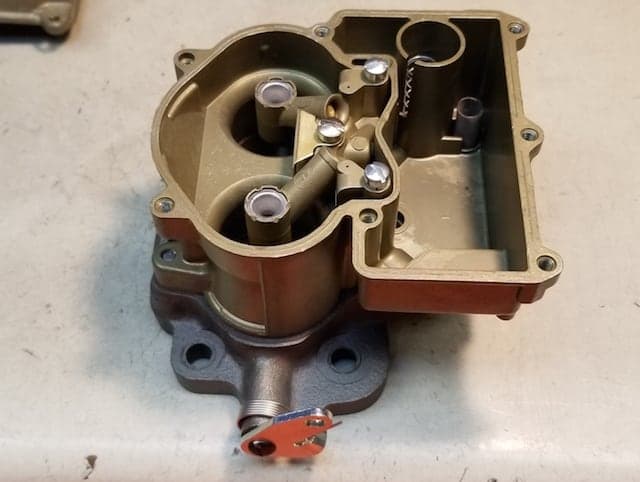

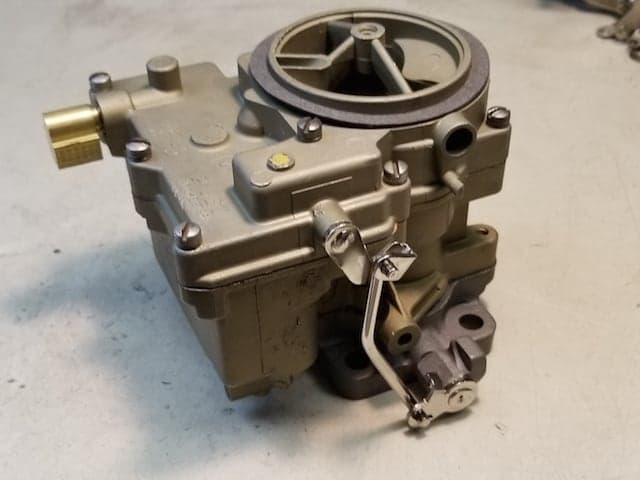

"Best way to polish weber carbs"

Q. Hi all this is a great forum/site, loads of info some of which I knew even more that I did not.

I am rebuilding a Ferarri V12 Engine I am replacing the injection for carb's.have polished a lot of bits but nothing with as many nooks and crannies as carbs. any bright (forgive the pun) innovative suggestions? and I have six of the beggars.

a V-12 with carbs

the carbs

the carbs

In anticipation Keith ;-)

Keith GrovesSad git with passion for cars and bikes - United Kingdom

November 10, 2010

Weber Carburetors & Parts on eBay (affil link)

A. Your best bet is a vibratory finishing machine. Basically this shakes up your bits with a lot of ceramic shapes that get into every nook and cranny.

As you may not have one of these to hand you might try one of the manufacturers such as www.vibratoryfinishing.co.uk/

Who might do the job or put you in touch with someone local who has one.

Take their advice on plugging holes etc before polishing or advise them of any sensitive areas.

Geoff Smith

Hampshire, England

A. They weren't polished when new and I'll think you'll be disappointed with the effort, cost and results if you attempt to polish them now.

I'd suggest you completely disassemble them, have the steel parts replated in zinc with yellow chromate, and blast the alloy parts with fine glass bead, plastic media or walnut shell media

⇦ on

eBay or

Amazon [affil link]

, after plugging holes as needed. They'll then look like the new one in your photo.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am looking to plate carburetors in dichromate finish (gold in color). I remember when I did it years ago it was done with mixing 2 different acids together -- boric and nitric I believe and adding chromate flakes. Where can I purchase these chemicals or is there another way to chemically plate them.

Mark Meyerscarburetor shop owner - Charleston, South Carolina

December 15, 2010

Q. Hi, I am rebuilding the cast iron carburetor on my 1960's John Deere 3010 tractor. After removing the grime and rust, what would be a good way to protect the cast iron from future rusting on both the outside, and especially the inside of the carburetor. Obviously the inside will be constantly exposed to gasoline (with 10% ethanol) and small amounts of water from condensation. All suggestions will be greatly appreciated.

Bill Jahn- Franklin, New York USA

October 16, 2016

Parts for John Deere 3010 on eBay (affil link)

Q. I am also restoring an old tractor, a W-9 McCormick Deering. From what I have read, zinc electroplating seems to be a good option. But if I'm inexperienced, how can I be sure to get a good plate on cast iron? What steps should I take to make sure the surface is well prepared? Also I understand that the carbon in the cast iron complicates the plating. How do I deal with that properly as a hobbyist?

Eric Minnaert- Savage Minnesota

December 5, 2016

Parts for McCormick Deering W-9 on eBay (affil link)

A. Hi Eric. I'm not totally confident that a hobbyist will be able to reliably plate zinc onto a cast-iron surface, but acid zinc plating is the way to go.

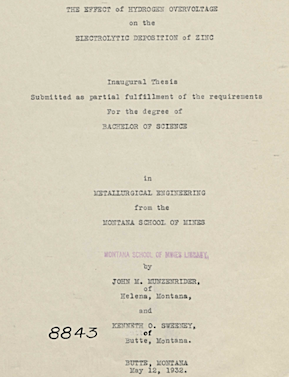

Cast iron presents a number of problems, but one of them is that the presence of carbon particles can kill off the hydrogen overvoltage, such that only hydrogen evolves, and no zinc will deposit. You may find that you can't get any zinc to deposit in the low current density areas. The article at right might be helpful though ⇨

Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Now, here is the question. I have read that Rochester Carburetor would Zinc Phosphate / Gold Iridite their carburetor bodies. Now understand these Rochester Carburetors are made of junk metal. It is basically the dross of the tops of the big smelting pots, very similar to pewter. Of course Pewter is a much better choice.

When done properly this Junk Metal would shine like an a Abalone shell. It would have a real Gold appearing shine to it.

Now, I have been trying to find a coater that can replicate this plating. Next to impossible!

Absolute Precision - Kapowsin, Washington United States

March 19, 2019

Rochester Carburetors & Parts on eBay (affil link)

A. Hi Daniel. "Junk" and "Dross" are perhaps a bit exaggerated, although zinc diecasting metal is relatively inexpensive. Zinc diecast metal can be difficult to refinish for several reasons...

The nature of hot diecasting is that the interior of the component is porous or cheesy, while the surface skin that touches the steel mold cools first and is hard and smooth. Once you penetrate that skin, the porous interior is difficult to reliably treat. But even the skin is not always perfect, if a spot on the surface freezes before all of the metal has joined together as a molten mass, you have a 'cold shut' -- where you've ended up pushing frozen metal together so there will be a small unsealed line where the frozen edge was.

When you want to refinish carburetors years later, you can't do much polishing without risking exposing the porous interior. And then too there may be some grain separation as the different metals in the composition have begun to agglomerate together over the years.

As I understand it, the rule of thumb for Iriditing these old parts is that you should zinc plate them first before Iriditing. It would seem to me, that it should be possible to zinc plate the parts, then lightly beadblast the plating for a matte appearance, then Iridite to a smooth consistent color.

But recently there is yet another monkey wrench in the works. Iridite chromate conversion chemistry of the old days used hexavalent chromium, which the world is moving away from due to toxicity and carcinogeneity. Instead, clear trivalent chromates are used but they are dyed if you want yellow.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Love your answer! Hate the Rochester base Junk (metal). It is very nice of you to compare it in nicer terminology. I have been doing these restores for quite some time. It is Fricking Rocket Science.

Love your answer! Hate the Rochester base Junk (metal). It is very nice of you to compare it in nicer terminology. I have been doing these restores for quite some time. It is Fricking Rocket Science.

The method used in cleaning, then time in a neutralizing bath, then rinse, then the time in the solution will all result in very different finishes.

I do not drink coffee or smoke a cigarette before I plate my perfectly, hospital clean parts. I use an evaporative cleaner specifically for my last step in petroleum removal. Usually, I have good luck. Sometimes I end up with G.I Joe looking garbage!1

I am at wits end! I am considering just Gold Plating the Dross Garbage Substrate and calling it good. My plated carbs almost look gold all the time anyway!

Ok, now since I am O.C.D, a Frustrated Artist and Functional Mechanical Contraptions are how I get my FREAK ON, I am interested in Perfection! Now do not get me wrong, my customers love me! I plate the raw metal with nickel or silver to stop rusting. No one has ever complained. I realize that the parts look far better than Rochester ever produced. They stay looking "Fresh off the Assembly line". This is important for me because your Muscle Car needs enough "Detailing" before shows.

The Zinc Metal used as a base for their carburetors gives me fits at times. I always do the same thing during the cleaning phase. Here is my method.

DO NOT EVER USE AUTO PARTS CARB CLEANING BUCKETS! I believe they pickle the metal and will ruin it in short time if left immersed in the cleaner!

I use Zep Dyna Blue , in my carburetor parts cleaner. I feel it is kind to the base metal. I do not use wire brushes etc to clean off the junk. Just fiber type acid brushes. Once clean I let them drip dry in the closed top of my washer. Then I give them a through cleaning with 3-M Evaporative Brake Cleaner

⇦ on

eBay

or

Amazon [affil link]

. I believe / hope it truthfully evaporates 98% of itself and other petroleum chemicals off the castings. I also do this not to contaminate my Glass Bead Booth Media.

After the 3-M evaporative clean into the Glass Bead Booth. I pay close attention to my blasting and spray paint my glass media blue so I can see it working and not penetrate the Hard Surface imparted on the exterior of the metal during cooling in the mold. Once I have complete coverage I blow them off with air.

Out of the glass booth they come. I inspect them with doctor's rubber gloves on. No bare skin handling. I even try not to breath on them. Once I am sure no grease, paint, stains, discoloration is present I place them into an Automotive Painter's Degreasing Solution. Purchased from any Auto Body Shop. Once again, they are agitated in this solvent, drip dried. Then my HOLY GRAIL STEP. I soak them in Alcohol. It seems to really have a Magical effect on the uniformity of the color retention. Once out of the alcohol solution they get baked in a scientific oven at low heat for 6 to 8 hours.

Then it is time for the Rocket Science. The heating process is also a prerequisite, but done at to great a heat, the JUNK METAL gets measles and warps, discolors and gets thrown into a trash can.

What else could I do? My colors look great. See pics. They even sometimes have the iridescence of old. I have been doing this for years and I am at wits end. There used to be other people that did this for me years ago, mortality due to chemical exposure has taken them away early.

- Kapowsin, Washington USA

Q. Really finding your method interesting, Daniel. My question is do the carb bodies go straight to the chromate?

Max Lacugnato- N. Sioux City, South Dakota

January 20, 2023

RFQ: I have a 69 Corvette that is all original except for the carburetor and the intake. I have found the correct numbers matching and build date (I think) carb. and intake manifold for the engine.

What would it take for me to persuade you to do your process on my original carburetor to get it back to a close replication of what it used to be?

Thanks,

Donovan

Business owner restoring forklifts - Camano Island, Washington

January 18, 2025

privately respond to this RFQ

Ed. note: As always, gentle readers: technical replies in public and commercial replies in private please (huh? why?)

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Does Chromate hold up to gasoline, as I want to apply yellow chromate to a stripped carburetor?

Jon Kirk- Indianapolis

August 11, 2021

A. Hi Jon. Yes chromate will hold up -- in most cases it is what was used originally on the carburetor. But if you are looking for an aesthetically pleasing coating on an old carburetor you may not be pleased, as you will read on this page.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I've learned that restoring older carburetors requires a Yellow dichromate wash to give the aluminum a tan like color - think Holley carbs. What would be a source for completing this process on some old Carter side drafts I have on my 54 Corvette?

Additionally I believe the restoration process of cleaning up this 60 year old aluminum is to vapor blast it to remove all grease and contaminants. Is there a final solution to wash the blasted product that prolongs the silver finish from corrosion and may also add a shine to the finished product that almost makes it look lightly oiled, yet dry to the touch?

I have a 1957 fuel "Rochester Ramjet" fuel injection system that shows dirt and exposure. Searching for the tools and processes to restore it.

- Houston Texas

April 16, 2022

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Carburetor cleaning and refinishing has been a perennial subject. Please see also --

• Topic 0338 "Zinc plating & chromating of Carburetors"

• Topic 11847 "Restoring gold Iridite color to diecast parts"

• Topic 16200 "Zinc plate carburetors & diecastings vs. chromating"

• Topic 33779 "Clean and brighten carburetor bodies"

• Topic 35697 "Carburetor re-plating / re-coloring"

Q, A, or Comment on THIS thread -or- Start a NEW Thread