-----

PVD coatings: color control

Quickstart: Many factors affect color, and a lot of developments in the color field are still held as proprietary, but this dialog offers at least general hints about moving in the direction of different colors or holding it where you wish.

For Engineers & Specifiers

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. We would like to change the optical colour of a PVD nitride coating. I have read modifying this can be done by changing the deposition parameters and gases.

But I have only found that for nitride films "increasing the oxygen content and nitride flow rate" is an alternative, but I could not find any technical information.

Does anyone know more about this? Does anyone have more recommendations? Thanks.

Engineer - Melbourne

July 6, 2023

A. Questions of this kind appear quite frequently. But there is no simple answer or prescription to obtain a specified colour which depends on many factors like atomic ratios of different elements elements present, texture of the coating, coating thickness, substrate properties, specific PVD technique used, bias applied, deposition rate etc. For example by varying the composition Ti:N:C one can obtain colours varying from nearly golden, brass, bronze, copper-ish etc. Coatings based on sputtering techniques are generally smoother and shinier than the ones based on arc techniques. Even when the technique is same different manufacturers would have their own variants. I am afraid every user has to develop his/her own recipe.

HR Prabhakara- Bangalore Karnataka India

A. Your question is way too general, as noted by HR. Decorative coatings for faucets, for example, are deposited on nickel/chrome plated brass at low temperatures. They do not have to be very hard or thick, so a wide variety of colors are possible. On the other hand, if your coating also has to be wear resistant, such as would be applied on a stainless steel orthodontic bracket, the coating has to be much thicker and harder, limiting the range of available colors but allowing for much higher deposition temperature.

You need to realize that PVD is a commercial process, so how to achieve specific colors and other performance parameters is generally regarded as proprietary information and almost never published. Suggest you either experiment on your own or hire a consultant.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. How can I get pink colour in PVD

Atul kumar- Narela/ new delhi, India

December 2, 2023

A. Maybe can use PVD + Anodizing, it's easier to get the color you want.

Rico, Gu- Suzhou [China]

August 26, 2024

⇩ Related postings, oldest first ⇩

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. I would like to know a PVD process for depositing coatings in different colors (red, blue...). Which is the best PVD process to make it? Which materials could provide the different colors?

Charo Fernandez- Valladolid, Spain

2001

A. Gold and brass colors are usually formed from zirconium nitride with small admixture of carbon. Chromium nitride yields silver. I don't know of any commercial work in red and blue, but would assume one can get blue by depositing titanium oxide. Erbium oxide yields a pinkish gray. The most common deposition process is by cathodic arc. Coatings are very thin -- around 200 nm.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

- for Q&A's about Gold colored PVD coatings please see thread 13115,

- and for black PVD coatings please see thread 35541.

A. I've some PVD plated steel samples that are in blue, black, grey and bronze colours, but I'm not sure the composition of the layer. Some French and Taiwanese platers can achieve those colours.

I've also read on the web that purplish red can be achieved by plating TiAlCN. You can surf the web for details. The plating is applied on tooling for wear resistance and high temp properties.

WY Wong- Hong Kong

A. Silicon nitride is bright blue. Also oxides can be deposited (or metals such as niobium can be anodized) that give a red or blue appearance. You just have to ensure the oxide thickness is uniform to give a homogeneous colour.

Best regards,

Mark JarrattPVD - Worcester, UK

2004

PVD Coating - Red color - Deposition Process Information

Q. I am a student studying engineering in Switzerland in EIAJ( www.eiaj.ch) in the surface treatment department and now I am seeking for colors deposition. I would like to get some technical infos about PVD plating a RED color. The time of deposition and the gasses used and the target material and all other technical information about the deposition process. Thanks in advance for the help.

RODOLPH A [last name deleted for privacy by Editor]EIAJ - University of Applied Sciences - LE LOCLE, NEUCHATEL , SWITZERLAND

2004

Q. Bonjour, J'ai lu votre post et suis interessé moi aussi par les differentes couleurs possible en PVD. Peut on avoir du rouge en PVD ? Nous utilisons le PVD pour du noir, bleu et doré...

David A- France

Readers are welcome to browse this site anonymously,

but its main purpose is worldwide camaraderie through sharing

-- so readers desiring that may not engage anonymous posters.

![]() Based on my superior language skills, I'll guess that is French for "me too" :-)

Based on my superior language skills, I'll guess that is French for "me too" :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

How to get blue PVD titanium coating

Q. Hello,

Please tell me how can I get blue colors while coating titanium on different scissors?

Please tell in PVD?

Quench Age - Sialkot, Pakistan

2005

A. Hello Shoaib,

Variation in the nitrogen gas level gives change in color of Ti coating. TiN is generally gold in color, if you go up to 500 sccm of nitrogen with lowest bias you get a reddish golden color. Including chrome in Ti material, i.e., TiCr with only Nitrogen gas in coating gives Blue color.

Research - Pune, Maharashtra, INDIA

A. We can get violet to red colors in TiCN by varying the Methane to Nitrogen gas ratio. Ratios are preferable like Methane:Nitrogen = 1:5 Red-ish yellow, like 1:4, 1:3, 1:2, 1:1(gray color).

YV Sambasiva Rao- Chennai, India

June 3, 2008

How to get PVD copper color other than TiCN

Q. I am an engineer working in a tools coating company. I have been working in PVD coating for about 3 years and still learning a lot about this technology. The PVD technologies I have experience on are sputtering, cathodic arc and little bit of evaporation.

Currently, I am looking for an alternative PVD copper color coating other than TiCN. In general, TiCN cannot withstand with high heat. However, the application for this coating has to be under high heat environment. From my understanding, ZrCN also can give you a copper color with high heat resistance. However, I am still not sure about the result. Does anyone have any suggestions. Thank you in advance for all of your responds and comments.

- Samutprakarn, Thailand

October 12, 2012

Q. This was also my question and I could not find any answer. I have read on the web that coated layer color depends on some factors such as target material, substrate material, layer thickness and ... I am interested in knowing about controlling these factors to make different colors. Is there any resource which provides details on how these factors can be controlled to make different colors?

Sara Qazvini- Tehran, Iran

December 28, 2016

A. PVD color depends primarily on the target material and the reactive gas mix. For example, you get yellow gold with a titanium target and nitrogen gas. Adding methane or acetylene darkens the finish, going to reddish gold to gray to black. There is no general recipe, just recipes that work for a specific PVD system design.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

Q. Hi, we use TiC to apply dark gray on stainless steel sheets. Sometimes color changes to blue after some days. What should we do?

majid mahmoudi- tehran, iran

June 24, 2020

Q. I am manufacturer of surgical instruments, dental instruments and beauty care instruments. I am new to PVD coating machines. I am interested to start this business. I contacted some companies and they said when I placed an order to buy PVD coating machine then their engineers will train me, but my strategy is first to learn colouring technique then will buy a PVD coating machine. Please share your expertise how to master coloring technique.

Thank you.

- Sialkot, Punjab, Pakistan.

April 12, 2021

A. PVD coating is not just about colouring. It is a technique to deposit metals, metal oxide, nitrides, carbides, etc., which is generally not possible by other means. They are used for their exceptional mechanical properties such as hardness, and also for their chemical, electrical and optical properties. The process goes something as follows:

The machine basically consists of a vacuum chamber in which solid cathodes like titanium, zirconium, aluminium, chromium, etc., are installed as per users' requirement. The parts to be coated are thoroughly cleaned, degreased and dried and then loaded inside the vacuum chamber. The chamber is then evacuated and often heated to a temperature in the range of 200 °C - 400 °C. Then a plasma is created on the surface of cathodes by processes like vacuum arc, dc magnetron discharge, rf magnetron discharge, etc., which can vary from machine to machine depending on users' requirement. The intense plasma on the cathode generates ions/atoms of the cathode material. These ions travel in straight lines and condense as a film on any surface in their path forming a coating. The parts to be coated are placed strategically in the chamber and are also rotated so that they are uniformly coated. They are also biased to suitable voltage to improve adhesion and quality of the film. If during the coating process a gas like nitrogen/acetylene/oxygen is injected at appropriate rate, nitrides/carbides/oxides can be deposited. The colour depends on the composition of the film you are depositing. For example titanium nitride has somewhat golden yellow colour. Thin transparent films can have rainbow colours.

The process is, in fact, more complex and many details are missing in the above brief description. There are many websites and review article which describe various aspects.

Bangalore Plasmatek - Bangalore Karnataka India

Q. Dear H.R.Prabhakara

Thank you for details you shared with me. Can you please share links or tutorials about PVD coating .

Someone told me that PVD coating machine for surgical instruments should be as per following specifications.

Size 1200mm/1400 mm

Pump h 150

Roots pump 1200

14 targets

4 sputtering targets

2x 30 pump

Diffusion pump 800 mm

Inverter with roots pump

Touch screen panel

Inverter cabinet

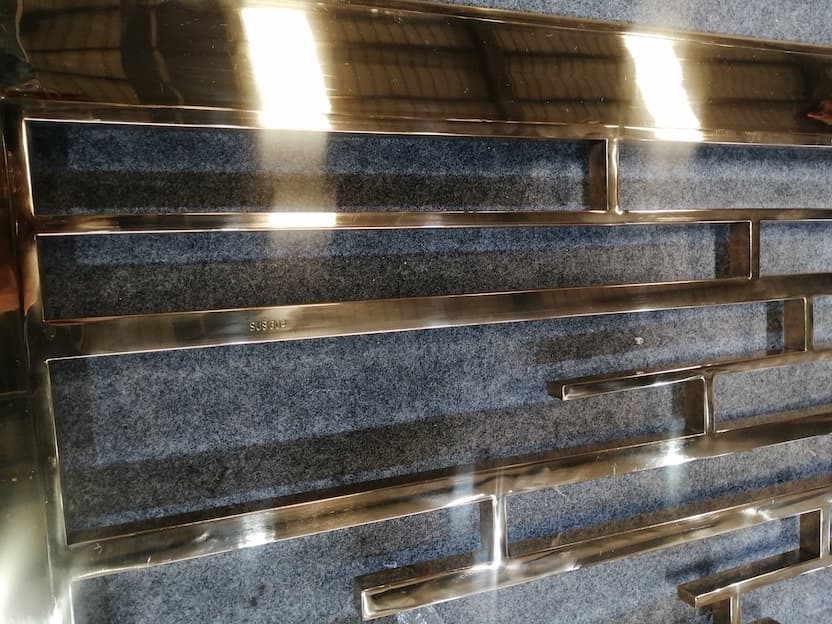

Please share your expert opinion whether PVD coating machine with the above mentioned specifications is suitable for plasma coating of surgical instruments. Colors required are: gold, rose gold, blue, pink, green, hard black and ceramic black color. Typical components: here and here.

Best regards

Farooq

Farooq Muhammad [returning]

- Sialkot, Punjab,Pakistan

A. Hi Farooq. Mr. Prabhakara is an expert who is welcome to reply to you if he chooses ... but free advice by definition never comprises 'expert opinion' :-)

You probably should retain the services of a consultant specializing in that field. Surely requirements like "14 targets" is simply a number from one particular supplier for one specific machine/package, not an inherently more valid number than 12 targets or 15; trying to evaluate anything from sales pap is usually hopeless -- but good luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. My Dear Mr. Farooq Muhammad,

Following links (which you might have already seen) may be of some help.

(1)Sputtering Physical Vapour Deposition (PVD) Coatings: A Critical ... https://www.mdpi.com/2079-6412/8/11/402/htm

(2)https://www.svc.org/Education/SVC-Education-Program.cfm

I cannot make any comment on the specific machine you have mentioned. It appears to be of Chinese or some similar origin.

I understand they are relatively less expensive compared to machines from Europe, USA etc. In the initial stages you may face some technical issues as I have heard from a couple of users of similar machines. My suggestion is that you get one or two batches of the medical instruments coated by the supplier of the machine and satisfy yourself. You would also need some additional equipment for cleaning the parts before coating.

Regarding the size of the machine, well, it depends on the number of parts you want to process per/batch/day/month. But the manufacturer seems to be offering his standard product.

It may be a good idea to visit their factory and learn more about the machine and its operation.

Bangalore Plasmatek - Bangalore Karnataka India

RFQ: I am interested to hire a consultant but I am not sure whether I would find one in Pakistan.If you know someone in Pakistan who has expertise and can provide consultancy please let me know.

Thanks in advance.

- Sialkot, Pakistan

April 23, 2021

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. Hi

Why is there colour difference in heavy bodies and light material in same run (batch)? Heavy bodies (Substrate) are little light in colour than low weight substrate. How can I compensate that colour difference? Will high temperature or high gas flow help?

Or do I need to run heavy and low weight articles in different runs?

Thanks

- Kurukshetra, Haryana

May 12, 2021

? What coating are you depositing, and what method are you using to deposit the coating?

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

Q. Hi I am jayesh fron India

How to get dark blue colour from decorative PVD coating?

How can I get red colour by multi-arc coating or by MF coating?

- Rajkot Gujarat India

April 19, 2022

A. Based on some work my son has done, I think it is possible to deposit blue and red coatings by a form of PVD. However, it is a very difficult process requiring very special equipment, as well as quite a bit of research work, and even then it might not be commercially viable. If you do find a way to do it, let me know -- there are many people interested in these colors.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

Q. I work on PVD coating machine (vertical one), in recent days the products that we work on take different degrees of color in the same process.

The gas enters effectively. We changed different targets with new ones. The ion works. What is the solution of this difference such that in one piece a side takes gold color and another side takes rose gold color. In the other hand the vacuum on the process reduces small.

Muhamad Mostafa KandelMechanical engineer - Cairo, Egypt

June 27, 2022

A. This could occur if the bias on your substrates is not right. You should clean your racks or fab new racks, as build-up of coating on the racks can affect the actual voltage on the parts as they draw current (higher resistance through the racks).

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. I want to know how to do bronze PVD coating -- like gas, targets and vacuum.

Hasmukh Parmar- Gujarat

December 5, 2022

|

|

Q. Jim Treglio: Why when painting a stainless product, defects appear in the color, such as removing the color from some places, or the product is pale and has no shine, and I cannot determine the location of the problem or the cause of it, is it the drying oven or the painting machine?

- Cairo Egypt March 14, 2023 Ed. note: You said "painting". Is that what you meant, or was it a translation error and you are talking about Physical Vapor Deposition? A. I can't help you. I know nothing about paint or painting. Suggest you talk to your paint supplier.  Jim Treglio - scwineryreview.com PVD Consultant & Wine Lover San Diego, California |

Q, A, or Comment on THIS thread -or- Start a NEW Thread