-----

Average cost of zinc plating

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. I am looking for Per LB cost of ELECTRODEPOSITED ZINC F01 & CLEAR ZINC PLATING Finishing to Carbon steel.

Siddhesh MahajanEmployee - Pune

May 5, 2022

A. Hi Siddhesh. Sorry, I don't know what "F01" means ... whose spec is it and what is the plating thickness? If you will describe the type of parts, and if we assume they are standard commodity hardware that can be barrel plated, sometimes when times are super-competitive, you may be able to get a price per pound -- but I doubt that shops will post it; they haven't yet in 18 years, but I guess we'll see :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

⇩ Related postings, oldest first ⇩

Q. What is the average or market price of zinc plating per square inch per certain measure of thickness. Thank you for your assistance. (This information will be used for Zinc plating market research project for West Virginia University's College of Business and Economics)

Joshua DeFelicecollege - Morgantown, West Virginia, US

2003

A. You have not even scratched the surface. What parent metal? What surface finish? What quantity? What shape? What size? What plater liability? What thickness? What chromate? What certifications - Mil Spec, GM, Boeing, Pratt and Whitney or Joe's junk yard? The location in a state will have a huge bearing, not to mention in which state. You cannot buy plating like a bag of carrots, which will also vary in price by over 100% in a given year in most locations.

James Watts- Navarre, Florida

A. Hi Joshua. Unfortunately, James is right. It also depends on whether the parts are barrel plated or rack plated. And wire goods like refrigerator racks may cost as much to plate as if they were solid sheets, despite their surface area being maybe 10 percent that of a solid sheet.

A barrel plater may occasionally, in a time of price war, give you a price "by the pound" to plate steel stampings even though everyone including him knows it's a stupid way to price. But try $.50 a pound for a medium size stamping if a wild guess will suit.

The truth is, a plater looks at his plating line, estimates the cost per hour to run it, figures out how many of your parts he can run in an hour, and starts from there. And he'll use whatever additional "cost center data" he may possess to make an adjustment for extra or lower loading/unloading cost, less zinc consumed for wire goods or more if a complicated shapes requires higher average thickness to reach a minimum thickness spec, etc. But it is almost impossible to give a generic price per square foot.

I've seen estimating books of all sorts, but have never seen one for plating. The only sure things about the cost of zinc plating are that it is less expensive than any other metal, and you can get it cheaper and crummier from China :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. OK...my last request for price information was so vague, that individuals responded that they needed more information. So, I am responding with more information...

I am looking for the COST of plating (zinc phosphate, hardcoat anodizing, and electroless nickel ion vapor deposition) for a research project in plating for my university.

Here are the specs for some hypothetical pieces my professor gave me:

Qty: 600

Component: Warhead Casing 7" X 6"

Type of Plating: Electroless Nickel Ion Vapor Deposition

Specifications: MIL

Blasting/Shot Peen: AMS & MIL

Baking: Yes

Testing: Thickness, Adhesion, Hardness, Embrittlement Relief, and Corrosion

Qty: 28500

Component: Missile Nose (no size given)

Type of Plating: Phosphate, Blue Topcoat

Specifications: TT, FED

Testing: Plating Thickness, salt spray, paint adhesion at proj. head level

Qty: 72500

Component: Missile Core (no size given)

Type of Plating: Zinc Phosphate

Specifications: ASTM, TT

Testing: Plating Thickness, Salt Spray

OK...this is the information my professor gave me...I must admit, I really don't understand most of it.

Student - Morgantown, West Virginia, US

2003

A. OK, This request does not include zinc plating. Because all of this is to MIL Spec, which requires significant extra testing and paperwork, the price is going to vary considerably from year to year. Probably your best bet is to send out some really nice mail to purchasing depts at companies that actually buy the products that you mention (on missiles) and in large quantities. You probably will not be able to quote or attribute the prices to their company. Martin-Marrietta comes to mind-- Orlando I think. Look under Lockheed as they merged a couple of years ago. You can get the exact information under the Freedom of Information Act, FOUA, but the request has to be extremely precise and is quite time consuming.

James Watts- Navarre, Florida

by John F. O'Hanlon

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi again Joshua. I still can't give a plating cost estimate, but I can probably help you a little bit with the problem of "don't understand most of it"

On the first item, "electroless nickel" means electroless nickel plating; this is an autocatalytic plating process (the reducing agent is in the solution, rather than requiring electricity to reduce the nickel ions to nickel atoms. Ion vapor deposition is a vacuum/PVD (physical vapor deposition) process used to deposit aluminum plating onto an object rather than nickel -- so I think there's a typo or misunderstanding there, unless s/he means the component is partially electroless nickel plated and partially coated by ion vapor deposition.

MIL means a military spec covering the electroless nickel plating and/or the ion vapor deposition. You can get these free at https://quicksearch.dla.mil/. AMS means Aerospace Material Specifications published by the Society of Automotive Engineers (these are not free). It is normal for aerospace components to test some portion of them for the thickness of deposit, the adhesion of the plating to the substrate, the hardness of the plating, that the plating has not hydrogen embrittled the substrate, and with an accelerated corrosion test like ASTM B117.

For the second item, phosphatizing (sometimes called phosphating) is a process usually employed before painting, to improve the durability of the finish in a number of ways. I don't know what is meant by 'blue topcoat' ... perhaps blue paint. I don't know what 'TT' means; FED means a federal specification (usually very similar to a MIL spec). Salt spray refers to the previously mentioned ASTM B117 test.

For the third item, zinc phosphate is one of the common phosphatizing processes (the other two most common being iron phosphating and manganese phosphating). It is sometimes used without subsequent painting, and it sounds like that is what is wanted here.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Multiple threads merged: please forgive chronology errors and repetition 🙂

Costing in a plating operation

Q. What are the cost drivers of a plating operation. In other words, when trying to determine the cost of a part, or for a quoting opportunity, how do you determine or estimate how much material, electricity and other inputs are "used" by a part.

Bill Rafferty- Milwaukee, Wisconsin

May 22, 2008

A. Hi, Bill. I have seen construction cost estimate "fake books" for a number of trades but I have never seen anything like this published for plating.

It is complicated enough that some large plating shops employ estimators who job is to prepare quotations (although I realize that an exact competitive quotation is a lot more work than a ballpark estimate).

But please explain the situation (volume of parts, type of parts, type of plating) and maybe people will be able to give at least a hint or two. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I WANT TO KNOW HOW TO CALCULATE ELECTROPLATING COST OF PRODUCTS MANUFACTURED IN BATH FITTING INDUSTRY. WHAT ARE THE BASIS OF COST CALCULATIONS? WHAT FACTORS ARE CONSIDERED? HOW TO CALCULATE SURFACE AREA?

THANKS

COST ACCOUNTANT - DELHI, INDIA

May 23, 2008

|

A. To All, process supplier - Great Neck, New York A. Mr. Garg, Plating Jobshop - San Luis Potosi, Mexico |

A. Hello,

also should be considered the following points.

- Time of preparing a rack (racking and unracking) according to labor costs/hr.

- Energy costs (heating, cooling, DI-Water preparation, electricity)

- Rack costs (Isolation of rack, material of rack etc)

- Cost per A-hr for additives which are in use

- Administrative costs (preparing of PO, invoices etc)

- Service-to-house costs (delivering, picking up part etc)

- Maintenance costs, material costs which are in use

- Packaging costs, special treatment of parts

- Insurances (transport, equipment etc)

Hope a little overview.

Saludos,

- Mexico City, Mexico

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. The cost of Zn plating is measured based on the component weight.But for powder coating cost is based on the area of component to be coated. Why is it so?

Rakesh Mahendiranengineer trainee - Nasik, Maharashtra, India

February 5, 2009

A. Reason 1 is that the powder coat part lends itself to calculating the area.

Reason 2 is that the plated parts are not always easy to calculate areas of complex parts, so management figured out that they could make money by using weight. This overcharged some customers and undercharged some, but on average, the plater made money. If he did not, he just raised the price.

- Navarre, Florida

Q. Hi James,

Do you have any idea how to estimate the plating price per Kg? Do you have any guidance to help me?

I am going to discuss/negotiate my plater price, but due to the fact that I never work at a plating company, I have a difficulties to estimate the price.

What I am going to negotiate to our supplier is plating price per Kg for Zinc plating, Zinc-iron plating, Zinc-Nickel plating and chromate conversion coating.

Thank you so much for your advice.

Best Regards,

Reynald

- Batam

July 16, 2009

? Hi, Reynald. What do you charge per Kg for your electrical and electronic components? It would help us determine the practicality and appropriateness of estimating the finishing costs per Kg :-)

Seriously, the idea that plating cost can be determined per kg is fatally flawed. But good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. In a few days time, I shall be negotiating a tube business that involves zinc electroplating as final finish

Typical size of tube (OD x Length) = 50 mm x 8 M

Coating required = 100 gm/Sq M

Inside tube coating is not critical.

What is thumb rule to estimate an approx. coating cost by weight or by size?

Thanks.

Factory manager - Chennai, India

February 6, 2010

Multiple threads merged: please forgive chronology errors and repetition 🙂

Zinc-nickel plating cost?

Q. Dear sir,

how can we know how much metal is deposited in Zn-Ni process when efficiency is 60%? Sir actually I want to know the costing of zn-ni alloy per kg or per sq. feet

Thanks & Regards

plating shop - India

September 23, 2010

A. Hi, Ashok

I believe that Zn-Ni alloy is deposited in the same thickness range as plain zinc plating, i.e., from a minimum satisfactory thickness of not much under .0002" to a practical maximum of about .0006". Proper plating cannot be costed on a per kilogram or per square foot basis, but requires a study of such factors as condition of the base steel, necessary cleaning and activation, required thickness of deposit, and chromate post treatment. Generally, unless you already have significant experience in estimating the cost, you are limited to getting several quotes. But it is good that you are considering "design for plating".

For a general feel though, pending correction by a plating shop, I'd say it will be more costly than zinc plating, less costly than nickel plating, and in the same general range as nickel-cobalt or nickel-iron plating.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. We are a plating shop and we have not been able to figure out how to cost our jobs, especially materials. Can anyone point us in the right direction?

Thank you,

Ginelle

- Houston, Texas, USA

February 7, 2012

Q. What will be the cost of zinc plating for the following specifications: yellow passivation, 14 micron layer thickness, trivalent (ROHS compliant), for a unit sheet of 1 m X 1 m X 6 mm?

Thanks a lot!

Shiv nadar university - Gurgaon,haryana and India

February 27, 2015

A. Hi Aditya. Hopefully a local plating shop will offer you a quote or an estimate. I've never seen a cost estimate book that includes plating services for the reasons that James explains. Further, some shops might have tanks of about 1-1/2 m deep x 2-1/2 m wide to well suit your part size, and others may have tanks where your parts just won't fit without a lot of wasted space, so they're poorly utilized. But zinc plating is the least expensive type of plating. The thickness of the plating will vary over the part (thickest at edges), but if you are referring to a minimum thickness, your thickness is about 2-3x the thickness of the cheapest "commodity" plating -- but is certainly not rigorous or unusual. I can't even venture a cost guess but maybe someone can. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

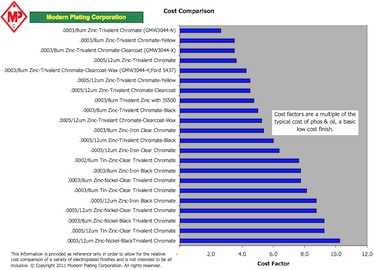

A. Interesting comparison on Zn-Ni and various finishes … the costs can vary very widely, from 2x more than the black oiled phosphate to 10x more than black oiled phosphate..

Just adding a thin plating to any metal is the start of a corrosion protection, it usually needs to be passivated and sealed afterwards. And those additional costs, as you see, can alter the total costs widely.

- Vienna, (The Coffee City), Austria

July 19, 2018

• Thread 43852 about Nickel Plating

• Thread 53013 about Gold, Silver & Jewelry Plating

• Thread 23629 about General Issues

• Thread 42981 about General Issues

Q, A, or Comment on THIS thread -or- Start a NEW Thread