-----

Silver plating on copper wire problems & solutions

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. Is the rate of dissolution and deposition same at constant ampere in silver plating bath? If yes, then how does metal increase over a period of time? Does high current impact the life of silver bath.

Jaiprakash Toshniwal- Ahmedabad, India

February 27, 2022

A. Hi Jaiprakash. Faraday's Law dictates that the same amount of electrochemical activity will happen at the anode as at the cathode. However, some of that electrochemical activity can go towards something other than dissolution and deposition of silver. It is not uncommon, for example, especially in cyanide-based electroplating, to generate a lot of hydrogen at the cathode. Any electrons consumed in liberating hydrogen means that many fewer electrons available to deposit silver. So metal content often increases over time as dissolution is more 'efficient' than deposition.

High current reduces cathode efficiency so it will accentuate the problem; and high current and/or temperature can contribute to breakdown of any brighteners as well. For the best help with your situation please try to tell us your situation, i.e., what is actually happening, rather than casting your questions as hypotheticals without context. Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. In case of high metal content, if we use 50% SS316L plates and 50% silver plates, will it restrict increase of metal content further, will there be any impact on plating.

Malay Sarkar- Kolkata, India

May 20, 2022

A. In general, it should help, Malay ... but again, you will get more & better help if you introduce yourself and tell us the full details of your actual situation. Hypothetical situations always introduce ifs-and-&-buts which discourage readers from responding if they don't want to get involved in pulling teeth :-)

For example, Robert and Sara assert in thread 51925 that those anodes will increase carbonates, but if they respond with that piece of information, now they will be the ones introducing possibly extraneous ifs-and-&-buts depending on your situation, like whether your silver bath is sodium or potassium based, which they don't know :-)

So please try your best to detail your situation. Thanks!

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇩ Related postings, oldest first ⇩

Q. I would like to use silver plated copper wire in the distribution transformer. It shall reduce the size of the transformer and the cost correspondingly. I would like to know if there is a possibility of putting this idea to practice and what is the procedure to make such a wire. The wire shall be covered by electrically insulated kraft paper and subjected to a voltage of 11000 Volts and shall be immersed in Transformer oil for cooling and providing electrical insulation. The problem shall be whether the silver plating will wear off in the oil and secondly whether it will peel off during the manufacture of transformer coil.

ARVIND AGARWALelectrical engineer - ALLAHABAD, UTTAR PRADESH, INDIA

2004

A. Hi, Arvind.

If plated properly it will surely not peel off, and I wouldn't expect it to wear off either. But surely you can simply buy silver plated wire without having to learn the art & science of electroplating, and installing an electroplating plant and waste treatment installation?

If you do decide to make the silver-plated copper wire yourself, please see "E-Brite 50/50 -- A unique cyanide-free alkaline silver plating process" by the site's supporting advertiser, EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser]. Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Dear Mr. Arvind,

Because the wire is electroplated, peeling is not possible. Moreover transformer oil will act as an anti-tarnishing agent so the silver will never wear off.

There are manufacturers of these silver plated copper wires and transformers.

- Meerut, Uttar Pradesh, India

July 11, 2011

Silver Plating Copper Wire at Home

Q. Hi,

I am purchasing some 200' of 10 GA solid copper wire with silver plate for electrical application. I am paying a premium for the silver plate (about 1.85 / ft for 110 copper). I generally use small quantities at a time - 75 to 100 ft.

Is there a way that I can use a silver solder and "silver plate" the wire myself? I imagine a process similar to tinning copper wire.

I looked at a typical plumbing silver solder but I see that it has copper in it. Could this create copper oxide? I need the plate to prevent oxidation of surface copper. Silver is what has been recommended to me for use. Local plating shops have balked at plating such a small amount of material and few are set up to handle wire.

Thanks ahead for all replies!

Regards,

Bob Leyendeckerengineer - Austin, Texas

2004

A. Dear Bob!

You can use simple immersion silvering solution (very thin silver layer, but very simple and cheap process).If oxidation is only problem maybe nickel plate is better solution.

Goran Budija- Zagreb , Croatia

Establishing a plant for silver plating copper wire

Q. Sir

I want to establish a company for silver plating on copper wire. So I want to know how to plate silver on copper wire economically.

Umesh Kumar- Chandpur, Uttara Pradesh, India

2004

A. If you want to silver plate copper wire in significant quantities, hire an expert consultant and be prepared to make a large capital investment.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

May 12, 2021

A. Hi cousin Umesh. You can certainly establish such a company if you wish! Good luck with the endeavor!

But this involves expertise in at least 3 broad technologies: electroplating, drawing of wire, and the mechanicals & electronics of continuous web processing lines. Unfortunately, no one could even begin to present all the necessary information in a posting appropriate to a public forum. However, when you reach the point where you can ask specific questions that can be answered in a paragraph or two, we'd be delighted to try to help you!

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Need better method for putting silver into plating solution

Q. Here in India we are plating copper wire with silver. In which first silver is melted & liquified with nitric acid, then precipitated with salt-washed-added potassium cyanide-electroplated on copper.

In this process when adding nitric acid the silver content shows a loss, is there any other method to dissolve silver in cyanide bath?

I heard about silver is placed in cyanide bath and given high voltage which allows it to melt but nothing more briefly.

we do have a license to use cyanide.

plating shop owner - Surat, Gujarat, INDIA

2007

A. You say that you are electroplating onto the copper, Nainesh. So what is the anode connection connected to, and why not just connect it to silver anodes and forget the nitric acid dissolution stuff? Am I missing something?

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Anode used is silver in solid form, silver is dissolved for transfer of silver onto copper wire (cathode).

Nainesh Patel- Surat, Gujarat, INDIA

2007

A. I apologize, Nainesh, but I am unfamiliar with what you are describing. As far as I am aware, silver platers uses silver anodes and silver plating solutions. I've personally never seen a professional silver plating shop try to melt or dissolve silver into nitric acid and add potassium cyanide. In the USA they might be arrested :-)

But maybe someone else has.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Mr. Patel

Best and easy way to get Silver potassium cyanide available in the market to use for plating purpose. Use brightener to get bright finish.

This is the easiest way, not what you are following now.

P. Gurumoorthi

electroplating process chemicals - Chennai, Tamilnadu, India

Q. Mr. Gurumoorthi is plating solution available in Gujarat?

What are the brighteners used in the process?

If somebody provider of the silver potassium solution please contact me.

plating shop owner - Surat, Gujarat, India

2007

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Ed. note: Hopefully a reader will see your posting and respond in private, Nainesh. Alternately, please see our Chemicals directory. Sorry, we don't publicly suggest brands or vendors in this forum (why?)

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I have a continuous silver plating plant for copper wire daily. I have 2-tone copper wire used for silver plating. but I am not satisfied with my process in comparison to other party. Silver plated copper wire is not looking more shiny and white. so tell me what I have to add in silver plating bath or another metal or solution add in silver plating bath.I will wait for your answer.

Desai Vatsal Vatsal R.- Surat, Gujarat, India

March 11, 2010

A. Hi, cousin Desai! Hopefully a reader will help you with this. But this is just a public forum, not a consulting service. No one posting here should "wait for our answer" because sometimes it can months before the right reader comes along :-)

Is this an immersion silvering operation? Is it a conventional cyanide silver bath? The chemistries of the two are far apart. What is the wire size and how thick is the silver plating please? And sorry, I don't know quite what you mean by "two-tone" in this context.Thanks!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Dear Desai Vatsal Vatsal R,

Many possibilities and not just one answer therefore possible. The answers could range from:

1. Add a brightener in your silver electrolyte (consult the professional suppliers to deliver one that fits your process or look on the electroplating sources of knowledge if you want to mix your own. Keep in mind that some brighteners harden the Silver or reduce the conductivity and I don't know your application) and/or

2. Check the electrolyte velocity at your wire surface and/or

3. Check/modify Ag strike condition and current to

4. Check for local too high current density and

5. Look for contaminants in your electrolyte.

Anyway, having a brightener added, you should implement controls (as for all the other parameters) in order to have a constant Ag quality. Therefore I agree with Mr. Mooney, hire a skilled person to guide you through. Good luck. Harry.

Harry van der Zanden

consultant - Tilburg, Netherlands

Q. We use silver cyanide for electroplating on copper wire in which we use 1.5 kg of silver, 4.5 kg of potassium cyanide and 20 g of silver nitrate in our bath.

How to bring more shine using minimum silver by electroplating on copper wire?

Bhupesh jariwala- Surat, Gujarat, India

April 11, 2021

A. Hi Bhupesh. What is the present silver thickness?

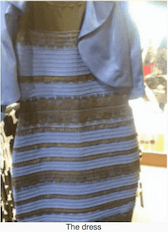

The colors in pictures can be quite deceptive as the world learned from "the Dress", which millions said was gold & white, while other millions claimed it was black & blue. But from this distance and your picture, your silver looks too thin to do more than impart a pastel tint; it doesn't look thick enough to impart a saturated color no matter how you tweak it.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Q. Sir, we use silver cyanide bath in silver electroplating on copper wire. Bath contains with water, 1.5 kilogram silver cyanide, 3 kilogram potassium cyanide and 20 grams silver nitrate. We pass copper wire from three dish contain silver cyanide bath. In bath we put thick silver patty as anode (our process time 6 hours, 6 ampere in rectifier. Copper wire weight per lot 50 kg 400 grams in 42 copper wire rolls each 1200 grams each). We apply 150 grams silver on copper wire which less from silver Patty which we put in 3 dishes.

(Click the graphic for pdf with 8 photos of plating installation)

Kindly tell us how we get more whiteness and shining using less silver in our silver electroplating on copper wires.

bhupesh jariwala [returning]- SURAT GUJARAT

A. Bhupesh

Electroplate the wire at a larger diameter, then draw to the finish size using diamond dies.

Unless your silver plating is total garbage, the finished wire will be mirror bright.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

Q, A, or Comment on THIS thread -or- Start a NEW Thread

on eBay

on eBay