-----

Do It Yourself Nickel and other Plating

Nickel plating is done on more different parts and for more reasons than any other plating. Hobby platers have some advantages over plating shops, making their life a little easier:

• The only requirement to be passed is the hobbyist's satisfaction.

• The item needn't come out of the tank finished because a hobbyist can polish/buff it, which is economically prohibitive for a production plater.

• Hobbyists don't need to run an 'equilibrium process' where the condition of the tank is identical when the plating is done as when it started; but production platers send a 2nd load in the moment the 1st is removed, then a 3rd, all day long, so nothing can be allowed to warm up/cool down, build up or deplete, or change in any way.

We'll try to provide answers & book knowledge, but plating is also a hands-on art learned through practice on scrap or unimportant stuff. Don't ask how to plate an item that is important to you first time out! The answer is to either send it out for plating or acquire enough experience & practice that you're ready first. Important stuff isn't for practicing on 🙂

Q. I'm looking to create a setup that will allow me to copper and nickel plate larger-sized restored vintage car parts.

This is a weekend hobby of mine and I've been doing it for some time with reasonable success, and most of my learning has been through trial and error. However, I'd like to be able to expand beyond small parts.

Everything I've done thus far is small (3-4 cubic inches at best) and I have no issue plating them in my gallon-sized glass solution tanks.

I'm now at the point where I'd like to do larger items. I tried plating some larger items that just barely fit in my one-gallon tank, but they didn't come out well. I believe the items needed more room for the solution to circulate and the anode to be further away from the object.

Ideally, I'd like to increase my solution tanks to about 2.5 to 3 cubic feet. The parts I'm plating have a polished side and a dull side (the back of the part) and the polished side is about 150 square inches (so 300 inches, plating front and back).

So my questions:

1. What kind of tank is recommended for that size of plating? I've been looking at HDPE food-grade containers. My ideal tank would be one where I could close it at the end of the work day to prevent contamination and spilling. Shape-wise, I'd want to get something that's around 24 to 30 inches (61cm-72cm) long by 12 to 18 inches (30cm-46cm) wide by 18 inches (46cm) deep. That's the ideal size for being able to plate the parts while still providing room for circulation, at least from what I'm figuring out. I'm assuming I can work with just two initially: one for copper and one for nickel, while using the smaller containers I currently have for acid dip, etc. Of course, I still have to clean up and put this stuff away at the end of the day. :-)

2. With larger containers like this, what's the best way to heat the electroplating solution? Would there be any issues with an aquarium-type heater? Similarly, for circulation, perhaps an aquarium bubbler?

3. What's the best way to rig up anodes in a large tank? Right now, I just use copper/nickel strips and those work well connected to the power supply by an alligator clip. I'm assuming a larger tank might warrant a second anode or perhaps several on a bus bar? And if so, where does one find something like that, or do you just make your own? (Yes, I've googled, but had no luck.)

4. For a bus bar type setup with (I'm assuming two or more anodes) is there a way to determine what kind or size of power supply I need? I'm assuming there's a formula for this, somewhere. :-)

5. Buying off-the-shelf electroplating solution in that quantity (15 gallons in 2 cubic feet) is very expensive (roughly $1200 for that amount) so I'm assuming that by graduating to this larger plating setup, it would be beneficial to start making my own solution? That's something I haven't gotten to yet, so definitely a learning curve if I go down that road.

6. Is there an issue if the solution sits for a while? I don't plan on using the solution daily (maybe weekly, at best, and most likely, monthly). With my smaller containers, I filter my solution before every use to catch contaminants. Looking at ~30 gallons, that would be a pretty large batch to filter...or is it recommended to use something like an aquarium filter?

Thanks for your time and advice (and for reading through this!!)

Hobbyist old car part plater - Chesapeake, VA

February 24, 2025

A. Hi Dave, we appended your inquiry to a pretty extensive thread on the subject of D-I-Y nickel plating, where you'll see plenty of second opinions.

1. Molded rectangular polyethylene tanks are available from plastic supply houses. The operating temp for nickel plating is 14o °F, which will make PE very soft, so I think you should plan on pressure treated wood 2 x 4 braces on the outside of the tanks just below their rims.

2. There are small electric heaters made for electroplating application. The glass on aquarium heating tubes may be resistant to nickel plating solution but not the electronics, and aquariums are never 140 °F. An inexpensive, ultimately disposable aquarium bubbler (or several) may be worth trying. Actual professional quality air agitation is not cheap, requiring perforated pipes in the bottom of the tank, and an external low pressure air pump.

3. The best bus arrangement arrangement is a brass rod spanning the tank to hang the work from, and two brass rods across the tank, one on each side of the work rod, to hang anodes from.

4. Bright nickel plating requires 40 amps per square foot of work surface, so if you're trying for brightness right out of the tank, that's what you'll need. If you're willing to buff to brightness, no reason you can't plate at 10 ASF.

5. No professional plating shop that I ever knew of formulated their own nickel plating solution. But if you're willing to polish and buff the work, so perfect proprietary brighteners aren't required, yes, you can formulate your own Watts Nickel solutions from Nickel Sulphate, Nickel Chloride, and Boric Acid.

6. The boric acid, and possibly some nickel will crystalize out when the solution is cool, but with careful management upon re-heating, you should be able to stir it all back in. In general, using components designed for water, like aquarium stuff, can't be expected to hold up to 140 °F acidic nickel plating solution. But look for all plastic little filter systems .

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thank you Ted! This is great information and appreciated.

Thank you Ted! This is great information and appreciated.

- Chesapeake, VA

February 28, 2025

Q. I am going from hobbyist to "big" hobbyist and building a copper and nickel plating system. The parts and pieces I've figured out. It's the chemicals I'm not sure of.

Both of my containers (one copper, one nickel) are 50 gallons each. They are actually 56 gallons, but I'm leaving open space. Anyway, I need to make 50 gallons of each solution: acid copper and bright nickel.

I've been researching online and have figured out I can buy "off the shelf" pre-made solution for $3250 USD for the nickel and $5300 USD for the copper solution.

Researching the separate ingredients, I come up with a price of $5013 for the nickel and then $1451 for the copper solution. The differences in price are what have me scratching my head!

Here are the recipes I'm looking at. Can someone please look at them and let me know if I'm screwing something up??

For acid copper:

50 gallons distilled water

46.2 kg Copper Sulfate

1.63 liters of sulfuric acid (37%)

510 ml of Midas brightener

The total price for the above is $1451 USD

For bright nickel:

50 gallons distilled water

58.5 kg Nickel Sulfate (this is $3100 by itself...so maybe my decimal is wrong??)

5.85 kg Nickel Chloride

7.8 kg Boric Acid

The total price for the above is $5013 USD

If my calculations are off, or perhaps I screwed up in my conversion from imperial to metric measurements, I could be spending a lot of money for no reason (and screwing up my solution!)

Thank you in advance for your help!!

- Chesapeake, Virginia

March 5, 2025

⇩ Related postings, oldest first ⇩

Q. Dear finishing.com,

I am currently restoring a 1960 Mini which has been off the road since 1966. I am trying to do as much of the restoration work myself, as a hobby.

To protect some of the steel components on the carburetor levers, etc. I would like to plate them for corrosion resistance. I was given some pure nickel anodes several years ago which I would like to use because the color is similar to bright steel and has good anti corrosion properties. I'm really not too concerned with the finish quality since the parts are functional rather than cosmetic (throttle stop lever, etc) but I don't want them to go rusty again.

I have a ready source of power in a car 12v battery charger ⇦ on eBay or Amazon [affil link] . I have a suitable container to use in an old ice cream tub, and have some copper wires to hang the parts with. Current can be controlled with 5w or 21w bulbs as necessary.

My question is, what kind of electrolyte can I use? I would prefer something easily available if possible from ordinary household chemicals, is this feasible?

I've tried several solutions already with no success at plating, although I have succeeded in producing considerable quantities of oxygen, hydrogen and even Chlorine (that was fun!). Before I blow myself up I thought I had better ask the experts...

I know it's possible to buy special "DIY plating kits" but they seem to be a lot of money for what they are, given that I have everything I need already except the electrolyte, and only have a few parts to plate. Of course, everyone seems coy about the exact content of this magic potion, making me even more sure it's probably something ordinary that I could easily lay my hands on at home!

Any advice greatly appreciated, I would like to make some progress with the restoration over Easter if I can.

Martin Savage- Ashby de la Zouch, England

2000

A. Hey Martin, You might be half right about the ordinary part, But, you still wouldn't plate a useful deposit. Only about 5 - 10% of the platers even try to make some of the chemistry used in plating/finishing.

The Coy part, for me any way, is mostly for your safety, and my environment. I have concerns. What do YOU (not you but some of the do-it-yourself-ers) do after the plating? Down the drain?

Earth week is just passed and for my part I'd like to let the professionals do the plating along with the waste treatment. Save our planet. I'll step down now. Plating really is more tech. than you think. Regards, Fred

Fred Mueller, CEF- Royersford, Pennsylvania

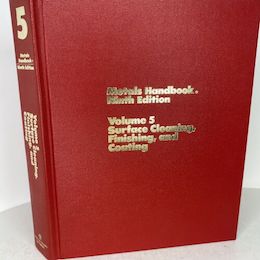

9th Edition, Vol. 5

"Surface Cleaning, Finishing & Coating"

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi, Martin. No coyness, a Watts Nickel plating bath is:

- - 225 to 300 g/l NiSO4.6H2O (nickel sulphate hexahydrate)

- - 37 to 53 g/l NiCl2.6H2O (nickel chloride hexahydrate)

- - 30 to 45 g/l H3BO3 (boric acid)

- - Operated at 140 °F.

- - 37 to 53 g/l NiCl2.6H2O (nickel chloride hexahydrate)

If you want it to be bright, the ASM Metals Handbook, Vol. 5 has a chapter that explains how to formulate a plating solution for yourself using readily available generic addition agents like coumarin, formaldehyde, saccharin and sodium lauryl sulphate -- and why you need four (4), not one. The balance of the info you seek is in that or nearly any plating book you can find -- please see our "must have" book list.

People aren't necessarily being coy when they are unable to distill the contents of a book into a two-paragraph internet answer to tell you everything about how to formulate nickel plating solutions and do nickel plating. Woody Allen famously made that point by saying he took a speed reading course, then read "War and Peace" in 10 minutes, and ... "it's about Russia" :-)

The "magic potions" you refer to are modern proprietary "brighteners" and "addition agents" which work better than the generic addition agents I just mentioned. They are the result of decades of research, and companies aren't trying to keep the info out of the hands of hobbyists who can't do synthesis from precursors anyway, but from their competitors who can. Hobbyists can use generic brighteners or they can buy proprietary brighteners -- but they can't make proprietary brighteners because they're not mixtures; "synthesis from precursors" -- is like making gasoline from crude oil. So it's best to buy the proprietary plating solutions, but you can certainly electroplate nickel without them, either using the older addition agents I mentioned if you wish, or by plating it with the Watts nickel bath and no addition agents, and just polishing/buffing it to a shine.

The principles of electroplating are very easy -- we have a FAQ "How Plating Works" that thousands of students have used to learn how to zinc or copper plate small items as a science project in just a few minutes. But practical plating is harder to do, and nickel plating your parts crudely will accelerate corrosion rather than retarding it, as seen on the fender of this 3 month old bicycle . . .

That's because nickel is a barrier layer plating of a more noble metal. Just as zinc anodes on boats corrode away to protect the steel hull, your steel parts will corrode away to try to protect the nickel plating if there are any tiny pinholes or any porosity. That causes the steel to rust bloom and pit in an effort to cathodically protect the nickel as you see in the pic. So, even though you are not concerned about looks, you do need full coverage and complete freedom from porosity.

Skill, knowledge, and experience are all very helpful in getting the best results, and are obtainable by practicing on scrap and learning! But ruining important parts, thinking plating isn't hard, not so much. Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

! As usual, you'll hear tons of 'don't do it' stuff on this site. Yet nickel plating is one of the simplest and most predictable of all the small time operations.

In fact there are several companies in England who sell very successful nickel plating kits. They even have 'electroless nickel' with its own SAFE disposal system, using steel wool ⇦ on eBay or Amazon [affil link] and a proprietary additive to accelerate the plate out. (This technique has often been promoted on this site, yet never mentioned when 'home DIY-ers are answered! Weird!)

If you have a search engine simply type in 'nickel plating' and spend half an hour surfing. You'll be amazed at what's out there. I'm sure you'll find several people who are prepared to sell you small quantities of nickel solutions.

Personally, I'd be more concerned if you were smoking cigarettes or drinking whisky than I ever would about you nickel plating! Perhaps this is just scaremongering to protect the plating shop subscribers here?

Here is a very simple formula that works extremely well: Formula to be added to 2 US Gallon Distilled Water Nickel sulphate 1700 gms, Nickel chloride 300 gms, Boric Acid 200 gms; operate at 1 amp per 10-15 sq in. of surface area, voltage @ approx. 1.5 - 4. You might find getting the raw chemicals more difficult than purchasing the proprietary chemicals available.

I. Wallace- LA, California

This is in response to a couple of Mr Wallace's comments.

1. Nickel is quite safe, unless you happen to be one of those that is allergic to it.

2. pH control was not mentioned. It only works well in a given range and is uglier than sin outside of that.

3. A brightener is necessary to get the bright "steel" look. without it, you get a matte tan.

4. It will take a huge bank of lights to get his 12 volts down to the 1.5 volts that he needs for a small amount of parts.

5. You are wrong, most of us that are or were platers, do not want the business. The history is massive bitching about the price because all we do is "dip it" in a couple of tanks. Also, while he will accept nearly anything for his own output, he very probably will not be that forgiving if a plater does it and it has a contact spot where he did not want one.

6. My experience is bad. Some home plater dumped his tank and it spiked the sewer system to nearly out of limits. I got to spend a day (unpaid) defending my operation and basically doing a mass balance accounting for all of my nickel. What do you think that my feelings are about "home" platers.

7. Platers are limited to an effluent of less than 1 microgram on nickel per liter of waste water. Your formula is about 1000 grams of nickel as metal, so is about 1 million milligrams of nickel. He probably will dump it because it is very expensive to get rid of it. If a plater had this much go to effluent, it would be over a quarter of a million gallons of effluent or a massive fine if caught.

8. Do you really think that most people will spend the $250.00 to have the treated waste tested for compliance? Or the $300 or so dollars to have the gal or so of residue sent off to the mandatory certified land fill?

With all due respect, I do not know the gentleman from England, so "He" refers to noncomplying home platers in general and not specifically him.

James Watts- Navarre, Florida

A. I am a chemist. I can see the concern of having to dump waste. However did anyone think if he is using small amounts to allow the water to evaporate when he was finished? He would be left with Nickel crystals and other goodies. Then he could simply scrape this into a container seal it up and find a chemical clean-up crew (yellow pages) who he can pay to dispose of it. Last I checked a few Kilos of many different metals (not mercury) were not expensive to dispose of if not combined with strange constituents. The key is getting rid of the water. Hell he could even heat it to get rid of the water faster. Most of the weight involved with chemical removal is in water, remove the water and lower the cost. Plus he does not have to dump it down the drain. Why do most people in the professional industry think home DIY are irresponsible. If he were he would have not asked for anyone's advice and continued creating gases! (by the way don't smoke dear any hydrogen gas one of the many byproducts of electrolysis) Many of these metals can be cleaned up with cheaters and I am sure the plating industry uses such organics to "lock-up" the bad chemicals to "so to speak render them useless".

Thank you,

Michael Moore- Dover, Delaware

2004

Hi, Michael. Evaporation for recovery of plating chemicals is fine, and widely practiced, but you need to "run the numbers" for the particular case. It is necessary to dilute the plating solution that is dragged out by about 1000:1 for successful rinsing, and that might be a lot of water.

You can evaporate rinse water in lieu of more complicated treatment, just as you can dig a hole for a concrete foundation with a garden tool instead of earthmoving equipment; but it might be practical for a dog house and not for a skyscraper. Thanks and good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Wow! Isn't this great, all fluff and no useful information in a website supposed to be filled with experts. Par for the course I'm afraid, If I ever find the answer, I'll be sure to come back and post it.

Wow! Isn't this great, all fluff and no useful information in a website supposed to be filled with experts. Par for the course I'm afraid, If I ever find the answer, I'll be sure to come back and post it.

GRRR!

frustration.

Robert Tinsley- Thunder Bay, Ontario, Canada

2006

![]() Hi, Robert. You're welcome to hold a low opinion of this site, but what "fluff" -- the formula including brighteners to make your own Watts Nickel pating solution? You want to follow the formula like a cake recipe, and the reason it's not working for you is that have a lifetime of general familiarity with food preparation but none with electroplating. Example: if a cake recipe says "add two eggs", you wouldn't throw unbroken eggs in their shells into the batter -- you know that the recipe implies a protocol of buying fresh eggs, keeping them refrigerated and recognizing if they've gone rotten, cracking them but not getting any shell into the batter, etc.; whereas the recipe I gave you says the nickel bath needs 30-45 g/l of boric acid, but will you simply throw it into the tank and cause plating problems or take the time to learn how? I can tell you the proper methodology, but as I tell you to put the boric acid into a spare anode bag while at operating temperature, you're confronted yet again with what constitutes the anode bag and operating temperature. Everything can be and is explained in complete detail here but it takes time & pages when starting from nothing, not 2 paragraphs. Why do you think plating books exist if 2 paragraphs can replace 200 pages? Why do you think plating managers & foremen earn good money if what they know can be picked up in 15 minutes?

Hi, Robert. You're welcome to hold a low opinion of this site, but what "fluff" -- the formula including brighteners to make your own Watts Nickel pating solution? You want to follow the formula like a cake recipe, and the reason it's not working for you is that have a lifetime of general familiarity with food preparation but none with electroplating. Example: if a cake recipe says "add two eggs", you wouldn't throw unbroken eggs in their shells into the batter -- you know that the recipe implies a protocol of buying fresh eggs, keeping them refrigerated and recognizing if they've gone rotten, cracking them but not getting any shell into the batter, etc.; whereas the recipe I gave you says the nickel bath needs 30-45 g/l of boric acid, but will you simply throw it into the tank and cause plating problems or take the time to learn how? I can tell you the proper methodology, but as I tell you to put the boric acid into a spare anode bag while at operating temperature, you're confronted yet again with what constitutes the anode bag and operating temperature. Everything can be and is explained in complete detail here but it takes time & pages when starting from nothing, not 2 paragraphs. Why do you think plating books exist if 2 paragraphs can replace 200 pages? Why do you think plating managers & foremen earn good money if what they know can be picked up in 15 minutes?

We told you which book to borrow from the library at zero cost to answer every question that was raised, including what generic brighteners, levelers, and wetting agents you can use if unwilling to buy a brand-name plating solution! You can attend monthly meetings of the American Electroplaters and Surface Finishers Society (www.nasf.org) in any area of the USA or Canada at zero cost and without being a member. You can view the 60,000+ pages of this site at zero cost, and we and our readers are happy to answer any and all questions cheerfully.

We have an FAQ that explains to elementary school children how to safely do zinc or copper electroplating for a science project. But we are simply unable to tell an untrained person how to graduate to industrial quality nickel plating in a couple of paragraphs. Meanwhile some steadfastly refuse to pick up the books we suggest from the library, and also refuse to try to learn any background basics like the nomenclature of chemistry :-)

And all the while, no matter how much time and effort we spend at it, the same people insult us left & right that we're working to keep this stuff secret so we can rip them off. Geez 🙂

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

I understand why people feel they get no positive response from this website, they don't.

I understand why people feel they get no positive response from this website, they don't.

All I see is read this book. Why have a website when all you are is a referral service.

Nickel plating is more simple than baking a cake and you need less items to plate than to cook.

Just do a web search for plating forums and in no time you will find sites that actually try and offer real help to a new person.

Anyone can say read this, when they cannot explain it themselves.

Sad.

- Elkhart, Indiana

October 10, 2009

![]() Hi, John. Thousands of school children around the world have learned how to do electroplating from our FAQ: How Electroplating Works. It includes how to do zinc plating and copper plating for a science project in tutorial fashion.

Hi, John. Thousands of school children around the world have learned how to do electroplating from our FAQ: How Electroplating Works. It includes how to do zinc plating and copper plating for a science project in tutorial fashion.

Our FAQ: Introduction to Chrome Plating is read by thousands of people every week and has been reprinted in several auto enthusiast magazines and on countless websites.

Virtually every conceivable question about plating in answered in exhaustive detail within the 60,000+ threads of this website.

But when you want to jump from grammar school science-project plating to useful, robust, bright, corrosion resistant, exterior, industry-ready finishes, it's not a matter of just reading 2 or 3 paragraphs like you wish.

Maybe you should look inside yourself as to why "book" and "library" provoke such hostility & rage?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() GO Ted! & Right on man, Tourists who think "just go!" Are Wak, Everything you posted is Clear..> DO YOUR RESEARCH ! the responsibility of craft is in the background info & so, until then , Go... First and foremost,Ted~ best & Clear.:>

GO Ted! & Right on man, Tourists who think "just go!" Are Wak, Everything you posted is Clear..> DO YOUR RESEARCH ! the responsibility of craft is in the background info & so, until then , Go... First and foremost,Ted~ best & Clear.:>

P.s *Grasshopper ask'd the Master, What is the sound of "One Hand Clapping"? ~ Master delivers a Open Handed "Slap" to the inquiring cheek. Right ! However Ted you are a genteel human,Good work & thanX, {Neva late when you wish to plate} Marcos.

Marcos Davidson

Au-Gusto inc - Melbourne Victoria Australia

A. As a bench jeweler I can say that all the back and forth is silly. Small part plating is very simple, contact any jeweler supply catalog and buy a bottle of plating solution, it's not that expensive. Polish and clean your part, place it in the solution and plate, rinse and dry. If you won't use it again let the solution evaporate and recycle the residue. If you want a fine finish, copper plate and polish again before the nickel plate.

Or you could just go to a jewelry repair shop and ask them to plate the part for you (most can plate pieces up to 4" x 4").

Gene Raiti- Columbia, Missouri

January 28, 2010

![]() Hello, Gene. Thanks.

Hello, Gene. Thanks.

Our FAQ gets school kids electroplating in 10 minutes or less; and yes, plating jewelry is almost as easy.

But when an antique auto enthusiast like Martin brings you their corroded diecastings to replate, you'll find that a bench jeweler will achieve nothing but to destroy them. Such parts teach a lesson in humility to world-class electroplaters :-)

Please prove us wrong! Simply take just one corroded old diecast car emblem or hood ornament and share with us how you did. My bet is after you've been completely unsuccessful after weeks of trying, you'll start to realize that plating diecastings and 'raw' metal is quite a different thing than putting a thin layer of a different color onto a polished, inherently corrosion-proof, piece of precious metal like what you are familiar with.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. I have also been looking for an answer to plating and stumbled across this page in the interweb. It is an interesting rant from both sides - I'm just wondering if the mini got finished. It does make me laugh at the people who want instant answers...here's how to build a house, for those that want to know......get some bricks, stick them together, make a roof....live in it. There, that is surely enough detail..after all, building a house is so easy for a DIY project. I can't see why Ted is so upset, all he does is offer his knowledge, gained over years of trial and error, for free, only to be slatted on line by people wanting instant answers... why get upset (sarcasm for the idiots that can't spot it).

You know what, I will answer the question (as I too have no experience in plating). Here's how to do it....

1) Make a box from chocolate.

2) Fill the box with a mixture of jam and rubber.

3) Attach the part you want to plate to spaghetti.

4) Fashion an electrical cable, into the chocolate, made from bamboo.

5) Switch it on.

6) You should have nickel plated thing.

Let me know if it didn't work...better still, why not have another go at Ted for trying to help (more sarcasm).

Thanks.

- Clacton, Essex, UK

April 27, 2010

I appreciate the fact that the procedures can't be explained in the same manner as in a book, but this is what the people expect from this site. Everyone does not have access to the library mentioned / not mentioned. This is why we click and surf the web. For all the posts backwards and forward the info in the books could have been explained already.

I appreciate the fact that the procedures can't be explained in the same manner as in a book, but this is what the people expect from this site. Everyone does not have access to the library mentioned / not mentioned. This is why we click and surf the web. For all the posts backwards and forward the info in the books could have been explained already.

- Vryheid KZN RSA

July 9, 2010

![]() So wherein is your difficulty then, Jc? The chemical formulation for nickel plating baths is already printed twice just on this one page, and we've already told you to try coumarin, formaldehyde, saccharin and sodium lauryl sulphate as your addition agents if you are unwilling to buy the packaged nickel plating solutions with modern proprietary addition agents which are impractical for an amateur to formulate.

So wherein is your difficulty then, Jc? The chemical formulation for nickel plating baths is already printed twice just on this one page, and we've already told you to try coumarin, formaldehyde, saccharin and sodium lauryl sulphate as your addition agents if you are unwilling to buy the packaged nickel plating solutions with modern proprietary addition agents which are impractical for an amateur to formulate.

But if you want to try your hand at synthesizing brighteners from precursors anyway, see thread 305 which tells you where to buy propane sulftone, 1-(2-Hydroxy-3-sulfopropyl)-pyridinium betaine, and N-benzylniacin.

We've already written FAQs for you explaining How Electroplating Works and an Introduction to Chrome Plating. We've answered thousands of questions about nickel plating in exhaustive detail on these pages, and provided a search engine so you can find those answers. Ask any detailed question and we'll answer it.

But the idea that books are unavailable in KZN is beyond ridiculous! From here in New Jersey, USA, I found a dozen plating books listed in one of your libraries in less than two minutes! I'm beginning to think that the reason some of the younger generation prefer public forums to books is that social media has trained them to not have the patience to quietly apply themselves even for 5 minutes without demanding that their bitching be heard, and the books won't listen :-)

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello.

I am trying to build small aromatic oil distillation units, cheap enough for a small farmer to afford. The herb-boiler unit is the problem.

It is to be made of stainless steel, but normal argon welding is very very expensive here & also not readily available. So, alternate is to do brass brazing (cheaper & readily available in small job shops).

Now, for corrosion, I have to coat the brass joint (brazing joint) with something. First I thought chromium plating but is seems it is very expensive & poisonous.

So, is it possible to do nickel plating -

1. I have to do without electricity

2. I have to do at home. When I approached professional platers, they refuse to do such 'small' jobs and also charge very high (saying that even for small jobs, their entire setup will be involved)

3. I am not at all worried about the 'looks'. Only corrosion.

I am looking for help in this respect.

Thanks.

George

- Dehradun, Uttarakhand, India

September 25, 2010

Hi, George. I don't think nickel plating is the answer for many reasons including the fact that it requires electricity, which you say you won't have. Please look into "tinning". This has been a rural trade for a hundred years, and thus sounds well suited to your needs. You can search this site for "retinning of pots" to get started. Best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thanks Ted. I am now looking at tinning option.

Thanks Ted. I am now looking at tinning option.

Also, somebody suggested to me to look at teflon coating if temperature is below 200 °C.

Regards

George

- Dehradun, Uttarakhand, India

A. One of the Turkish kids in my village asked what a Watts bath is and could I make one. Having given up with his chemistry teacher he thought he would try a retired miserable lawyer for the answer! First of all BUY A GOOD PAIR OF GOGGLES AND A PAIR OF RUBBER GLOVES AND WEAR THEM AT ALL TIMES DURING THE FOLLOWING PROCEDURE.

I used the formula of 1 kg Nickel Sulphate, 220 g Nickel Chloride and 160 g of Boric Acid added to 4.5 liters of deionized water to make a Watts Bath. After mixing the chemicals together I added some nickel brighteners available from eBay plus a couple of saccharine tablets from Hot Lips Hasan, our local chemist come plumber. I tipped this lot into a large glass tank, added an cheap fish tank heater set at 34 °C and an cheap fish tank pump/filter. Using pure Nickel ingots (from eBay UK) and a 5 volt power supply capable of 100 ma per inch we were ready to go.

I had been meaning to plate some old steel Train model rail track for years so decided this was the time. I immersed the track in a weak hydrochloric acid solution to clean it as much as possible and then washed the track with a strong solution of wash-up liquid finally running the track under the clean water tap. After cleaning and drying the article you want to plate don't touch it with bare hands or let any mucky Turkish schoolboy anywhere near it, use your Marigolds (rubber gloves) or better still suspend the item from the copper wire you will be using in the plating bath. To save space here go to google and type in Nickel Plating to find out how to connect everything up to the 5 v supply. I suspended the Nickel ingots from titanium wire although I am sure something much less exotic would suffice. The track was suspended in the bath in a copper wire basket which was easy to construct from household solid power supply cable, Plating time varied so it's best to practice on waste items first until you are happy with the result.

The Eurostar and SNCF TGV not to mention the Flying Scotsman has been running fine around my garden on nicely plated rust free track for months now!

Hope this helps and please be patient with your plating and also with those running this site as they are only trying to help.

- Mersin, TURKEY

November 3, 2010

![]() Very happy to hear of your success, Paul. Thank you greatly for taking the time to share the info!

Very happy to hear of your success, Paul. Thank you greatly for taking the time to share the info!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. First, I am no chemist so I get lost in quick in this subject.

I want to restore and dress up some old tools, new projects and things.

To do this I want a simple nickel plating system.

The biggest problem I think I face is a good cheap plating solution.

I have watched youtube videos and looked on eBay for the chemicals they use.

Nickel sulphate, Nickel oxide powder

Nickel sulphate seems cheap but I haven't found a formula to make a plating solution with it.

Nickel oxide powder looks expensive how far does 50 grams go when plating?

Will I be able to plate aluminium, steel, cast iron?

would I need to copper plate any of these first?

Is a nickel anode required for all solutions or do some provide all the nickel from the solution itself?

It looks like most solutions have temperature requirements.

What voltage & current is best for the plating? Electronics I do understand well.

Any help would be appreciated.

- Cedar Lake

April 7, 2012s

A. Most people will not like the product they get from a garage shop home plating, unless they have a complete kit and good guidance.

Proper cleaning and activation are just as important as the plating step. Hard material needs to have a bake cycle after plating.

Legal disposal of the solutions is extremely expensive. An EPA violation typically starts at $500 per violation.

Why not find a shop that will take it as a filler job. It will be cheaper in the long run.

- Navarre, Florida

April 10, 2012

! My elderly aunt started volunteering at the local library, and I warned her that they had BOOKS there and if she wasn't careful, she might LEARN somethin'! WATCH OUT!!!

Adolph Kurdyla- Geneva, Florida, USA

April 26, 2012

Q. Greetings, I restore antique toy sewing machines and most of the moving parts are nickel plated. I am building a plating operation of my own in my hobby room and am ready to try it out. I've just completed the power supply portion. I'm using a battery charger ⇦ on eBay or Amazon [affil link] which is controlled by a home fan rheostat. I have a volt/amp meter installed in the line.

In my reference book I'm given a formula using nickel sulphate, ammonium sulphate, magnesium sulphate, boric acid. I have all these chemicals except nickel sulphate which I'm about to purchase. Now I see in your forum that nickel chloride is used. My formula mentions nothing about this item. I'm going to be plating raw steel. I will pickle the parts after sandblasting the old nickel off. Can you help me with the bath solution? Bob

Bob Benedict- Humboldt, Tennessee USA

March 4, 2013

A. Hi Bob. Beautiful crafts room.

Sorry, I've never heard of your nickel plating solution. The most typical process is Watt's Nickel, which I described in my first response on this topic. You may be able to do without any brighteners since you may be content to buff the nickel to brightness yourself. Just remember that nickel plating will accelerate the rusting of steel if there is porosity or pinholes, so watch for pinholes and plate thick enough that there is no porosity.

If you are sandblasting the parts, and you do the nickel plating immediately after the blasting, there should be no further need for cleaning or pickling. Try going immediately from sandblasting to nickel plating. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thanks Ted for your response. The reference book I am using is called "Hobbyist electroplating made easy". It lists 3 different Watt's baths plus 3 others in the same text. A couple of pages further on it says that if you are plating directly on steel this formula will work great.

Thanks Ted for your response. The reference book I am using is called "Hobbyist electroplating made easy". It lists 3 different Watt's baths plus 3 others in the same text. A couple of pages further on it says that if you are plating directly on steel this formula will work great.

Nickel sulphate, ammonium sulphate, magnesium sulphate, boric acid, 100-130 °F, .1 amp per sq inch cathode and 2.5-4 volt. I've already purchased all these ingredients, so I'm going to give this bath a try. I'll let you know how it goes. This is my first shot at plating myself. I have always paid for the service. After this I may be back paying.

- Humboldt, Tennessee, USA

Q. One more question. Does the nickel being plated come from the Nickel sulphate or is a nickel anode necessary also? If an anode is not used, what is used in it's place? Thanks again, Bob

Bob Benedict [returning]- Humboldt, Tennessee, USA

A. Hi again. Nickel anodes are necessary. Larger platers use nickel "S-rounds" in titanium baskets, but you could probably get away with wiring S-rounds with titanium wire if you can't find small titanium baskets.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Ted, Here's where I'm at. I understand now what your talking about with titanium baskets and S-rounds. Since I've had little success in locating these items at a reasonable price, I'm going to try plating with nickel sulphate and ammonium sulphate instead of nickel chloride using a strip nickel anode as my hobbyist book says. I'll let you know what happens. Any help you can give me as to where I can buy small quantities of S-rounds and a small basket and bag if my plan fails? Thanks so much for your help so far. You've taught me a lot. Bob

Bob Benedict [returning]- Humboldt, Tennessee USA

A. Hi. The nickel strip might be just fine for hobby plating; it's just not as ideal as S-rounds in a titanium basket or strung together with titanium wire. S-rounds are sulfurized nickel; the sulfur helps the anode dissolve faster. Without it, what happens is replacement nickel from the anodes doesn't dissolve into the plating solution as fast as the nickel plates out, so the plating solution gradually gets weaker. In a high production plating shop where thousands of pounds of parts are plated every day, and where the nickel plating bath must go years without dumping, it is very important that the nickel content remain constant by the anodes dissolving just right. You might never have a problem worth worrying about just using your nickel strip.

But for the S-rounds , google for "hobby plating".

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Ted. Here's the outcome of my first attempt at nickel plating. I tried a part that measured 3"x3". I had sand blasted it about 2 weeks ago. I was able to control the amps and voltage without any problems with my home built system. I run 4.1 volts and 1.8 amps for 15 minutes. The finish was very light. I couldn't buff much gloss to the part. I believe I did several things wrong. First, I sand blasted and let the part sit for almost 2 weeks. Secondly, I didn't wash the part before I plated it. It had to have dust on it from time sitting and blasting. Thirdly, I don't think I let it in the tank long enough. I'm going to scrub the part with soap and water and try again. Can I use tooth picks to protect threaded holes from plating? I assume any part touching the hanger wires will not plate, correct? I could see the particle movement from my 1"x6" flat nickel anode during the process. Still having problems finding round nickel anodes. Any comments or suggestions would be greatly appreciated. Bob

Bob Benedict [returning]- Humboldt, Tennessee USA

March 17, 2013

A. Hi. If your part is 3"x3" and two-sided, the surface area is about 18 square inches, so 1.8 Amps is about 14.5 ASF; that sounds like a good current density. It's about 1/3 of what's used in industry, but it's a good number when you lack filtration and air agitation. But it means you have to plate 3x as long as industrial platers do, and they would probably plate for a 1/2 hour. So you could plate for 6 times as long (6x as thick) before anyone might think it excessive.

Yes, you should plate immediately after sand blasting, but then it shouldn't be necessary to wash it, but doesn't hurt.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Why do we need to use "titanium" baskets or wire to hold anodes?

And, how does this forum work? It seems to take days for my posts to appear but is responded to within one day, sometimes the same day. I love the site, just curious.

Thanks again, Bob

Bob Benedict [returning]- Humboldt, Tennessee USA

March 20, 2013

A. Hi Bob. Most materials other than titanium will be attacked by the plating solution or will dissolve into it, contaminating it. If you can connect your nickel anodes to the power source above the solution level, titanium isn't required,

In judging the forum, please judge it by its stated goals of providing a technical resource about metal finishing, and a place for people to enjoy the camaraderie of their peers.

We don't compete against metal finishing consultants (whose support helps make the site possible); so offering timeliness & personal attention isn't quite the goal :-)

All submittals are manually edited & posted because our experience has been that there is no other way to keep the place from becoming a spamfest and to avoid the hostility you see in the comments on Facebook postings.

We post answers that have been sent to us before we look at new questions. So it can take a while to post new questions (remember that this thread is one of 60,000, so you are not seeing all the work that's involved). Answers sometimes come very quickly because I simultaneously post my answer with your question or another reader responds immediately.

Glad you like the forum. Thanks for the kind words!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Thanks for the explanation of how the site works. Here all along I thought I was the only hobbyist out there trying to nickel plate at home and I had your undivided attention. LOL I am plating and receiving excellent results from my home built plating line. Something strange happened to my bath after sitting in a closed jug for a couple of days. I went to plate again today and when I emptied the bath into my plating tank, it had a large amount of crystalized substance in the bottom of the jug. I emptied that into the tank also thinking I could dissolve it again once I heated the bath. Even with this hard substance in the bottom of the tank, the plating process went very well. They didn't dissolve at all. This time I left the crystals out when I emptied the bath into my storage bottle. Do you think they can be powdered again and dissolved during another session of plating? I hope this is not my nickel sulphate. They are blue just like the sulphate when I purchased it. Any ideas? Bob

Bob Benedict [returning]- Humboldt, Tennessee, USA

March 20, 2013

A. Hi. The blue-green crystals/solids are indeed nickel salts. They are more soluble at 140 °F than at room temperature, so this settling out is not a shock. But you probably have more nickel in solution than you need if the solution is this saturated. Glad to hear you are enjoying success.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

(you are on the 1st page of the thread) Next page >

Q, A, or Comment on THIS thread -or- Start a NEW Thread