-----

Non-cyanide silver plating for jewelry & silverware

Q. DEAR SIR

I WANT FORMULA FOR SILVER PLATING CHEMICAL FOR PREPARING NON CYANIDE BATH silver leg chain jewelry. PLEASE SEND ME PARTICULARS FOR SUPPLYING CHEMICAL AND BRIGHTENER USING CHEMICAL DETAILS. I need supplier address also thanking you sir.

Feroz F [last name deleted for privacy by Editor]r.s. PLATING - Salem, Tamilnadu, India

2004

2004

A. Hi Feroz. EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser], Technic, Zinex and probably others offer non-cyanide silver plating processes, but this free site is for camaraderie and technical info, not for commercial sourcing. The advertisers who make it possible for you & I probably don't want us spending their money keeping current the contact info for their competitors who prefer to pay nothing :-)

Although non-cyanide silver plating reduces the safety hazard (see http://p2library.nfesc.navy.mil/P2_Opportunity_Handbook/1_10.html ⇩ for example), it is not quite the equal of cyanide silver decoratively. Be careful that you don't put yourself out of business by shipping unsalable jewelry :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

[Ed. update: The above link is broken -- don't go there. Thankfully, Internet Archive preserved a copy here

These days information often never sees print, then disappears forever. If that concerns you, please consider a donation to The Internet Archive.

2004

A. You can use next formulation:

40 gm silver chloride

200 gm potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

20 gm potassium carbonate stainless steel or silver anodes

60-80 °C temp.,10-15 A/sq.ft.

(according to J.Fischer,D.Weimer: Precious Metal Plating [on Amazon affil links], Teddington 1964.)

Goran Budija- Cerovski vrh Croatia

2004

Q. Dear Goran,

I am very interested in your formulation given and as I am also seeking a non-cyanide silver plating solution which provides a brightener-free "white" finish for engineering applications; I would like to know:

1. Would this formulation be able to give me 7.62-12.7 microns of silver?

2. Would I still require a silver strike to improve efficiency?

3. Would this solution be a compatible finish to apply after a Woods' nickel strike?

Any help you can provide would be greatly appreciated.

Nigel Gill, B.Sc MIMF MRSC- Glasgow, Scotland

A. Dear Nigel!

I am just metalwork conservator--and I have used that type of bath over ten years, but without any scientific control (current density, cathode efficiency, thickness control etc.). I have even used it for small scale electroformings (0,3 -1 mm thick), and it works well. According to ex USSR literature(Yampolsky:Precious metal deposition, Moscow 1961., and P.M. Vjatcheslavov, S.R. Grilihes, G.K.Burkat, E.G.Kruglova: Galvanotehnika blagorodnih I redkih metalov/Electroplating of precious and rare metals/,Leningrad 1970.) You can work without strike (except stainless steel, you must activate it). Good luck!

Goran Budija- Cerovski vrh Croatia

2004

September 5, 2008

Q. The original reader asked for a non-cyanide plating solution. Goran suggests using a solution containing ferrocyanide (i.e., the solution does contain cyanide). Am I correct or am I missing something obvious? (Note I'm an electroplating novice).

I myself am looking for a non-cyanide based silver electroplating solution. My application is a micro electromechanical device for DNA detection. I require around 5 µum of silver (which I shall coat with AgCl). The silver appearance does not have to be particularly good - i.e., shiny.

I have found several papers on plating from a solution of AgNO3 dissolved in aqueous ammonium hydroxide (ammoniacal silver hydroxide). These papers are written by a reputable guy called Brian Polk from The National Institute of Standards and Technology, Gaithersburg. See for example;

Journal of Electrochemistry Society, 151 (9) C559-C566 (2004).

In some other topics I noted that Ted Mooney has concerns over the explosive nature of ammoniacal silver nitrate if it is allowed to fully evaporate. Polk in the above paper also expresses these concerns; however, he states, "Some sources indicate silver nitrate in aqueous ammonia

⇦ on

eBay or

Amazon [affil link] may produce explosive salts within hours after mixing, while other sources claim the solutions are stable for months. Solutions for this work were stored in the dark and used for up to a few weeks before deactivation with HCl." I'd be interested to hear your comments on that Ted.

I've also cheekily tried to contact Technic USA to find out exactly what is in their non-cyanide based Ag electroplating solution. Unsurprisingly they haven't told me!

Finally a question - does anyone know of any other cyanide free Ag electroplating solutions apart from ammoniacal silver nitrate?

Many thanks,

- Glasgow, UNITED KINGDOM

A. Hi, James. Sodium chloride does not pose the dangers of either sodium or chlorine, and Goran's point was that a similar situation applies to ferrocyanide despite the fact that the word contains cyanide.

I'm just a guy with some plating industry experience, and unqualified to talk about silver fulminates beyond the general warning that one should certainly look into them before experimenting with silver plating home-brews.

Other suppliers of cyanide-free silver plating solutions include Zinex and EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser]. You are correct that suppliers usually will not disclose the full details of their development efforts, but often you can find the general basis for the chemistry from their technical data sheets and MSDS. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

September 5, 2008

Multiple threads merged: please forgive chronology errors and repetition 🙂

Cyanide-free silver plating for hotel EPNS wares

Q. Please show me the way to a cyanide free silver plating for hotel epns wares.

thank you

silver plating on hotel EPNS Wares - Hyderabad, India

2005

2005

A. Simple cyanide free silver plating bath:

40 gm silver chloride

200 gm potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

(1% of potassium cyanide toxicity)

20 gm potassium carbonate

1 lit water

stainless steel or silver anodes

60-80° C,10-15 A/sq.ft

According to Fischer,Weiner

434, Teddington 1964.

Or you can use pyrophosphate bath:

100 gm potassium pyrophosphate

25 gm ammonium carbonate

25 gm silver pyrophosphate

1 lit water/SS anodes

According to "Galvanotehnika blagorodnih I redkih metalov" (Electroplating of precious and rare metals), Leningrad 1970.

Good luck!

- Cerovski vrh Croatia

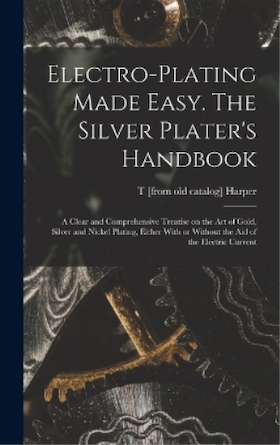

by T.V. Harper

(classic reprint of an old book)

on AbeBooks

or eBay

or Amazon

(affil link)

Q. Dear Goran, I would like to thank you for this response.

The mentioned process landed me in some trouble.

I would be thankful if really there exists silver plating without cyanide.

Regards and thank you.

silver plating on hotel EPNS Wares - Hyderabad, India

2006

A. Hi C.K.,

I think Goran was making the point that ferrocyanide is not cyanide any more than NaCl table salt is sodium or chlorine. Some chemicals should scare us, but we should not let spelling do so.

But last week I attended a presentation on "Alkaline Non-Cyanide Silver" by Eric Olander of EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser], Ravindran. Cyanide formulas still account for 95 percent of all silver plating, and there is no decorative non-cyanide formulation quite as good looking as cyanide silver because no brighteners are compatible. But maybe you could try their non-cyanide silver and see what you think.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2006

2006

![]() Dear Ted,

Dear Ted,

Thank you for the information.

So it is all a hoax that a non-cyanide silver plating ever exists.

Then what is available other than the ferocious cyanide based silver plating, because it was the world body from USA who had come to Delhi etc in 1999 and successfully paved the way for the closure of all the plating units based in the star hotels without giving any alternative. The stainless steel cutlery, etc. seems more of a large open air dining outlet, there is no glamour which otherwise existed in the hotel even if the service was not good.

Regards.

ravi

silver plating on hotel EPNS Wares - Hyderabad, India

A. Dear Mr. Ravi,

You make reference to events that I unfortunately have no knowledge of, such as this "world body from USA" visiting, and electroplating within the star hotels, etc. But maybe I can guess that these hotels formerly did their own cyanide silver plating in-house and someone decided that it was not safe for hotels to do cyanide-based plating on site?

I see two good alternatives: purchase proprietary non-cyanide silver plating processes rather than trying to formulate your own, or use electroplating jobshops in your area who can do cyanide silver plating of silverware at their shops. Either approach would allow you to once again use fine silver service without exposing the general public to dangerous industrial processes that only trained professionals should have to deal with.

Despite my ignorance of what went on, times have changed; and I feel that when hotel guests lie down at night, they should not need to worry that hazardous industrial processes are in progress within their hotel that could subject them to deadly poisonous gasses. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2006

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am making a copper bowl, but want to plate the inside for food safety reasons. I have heard (mostly from this website, which is incredibly helpful) that at-home silver electroplating is pretty much impossible due to the fact that it needs/creates cyanide. I have heard of a product called "CleanEarth" that claims to be true silver plating but is cyanide-free. Does anyone have experience with using this product?

Thanks!

engineering student - Stanford, California

February 3, 2010

A. Hi, Megan. If Clean Earth claims it is cyanide-free, it probably is. If you try it, please get back to us -- we'd like to know how it worked out.

We've talked to the principal suppliers of non-cyanide silver plating solutions and been told that they only sell it for electronic applications, not decorative applications because, as mentioned on our Silver Plating at Home FAQ, the color isn't quite perfect.

But a consumer may be far more accepting of a slightly off color on a few D-I-Y items than they would be with purchased items. If you purchased flatware and your guests were noting how the pieces didn't quite match in color, you'd probably want to return it -- whereas if you had replated it yourself, you'd probably welcome the comment :-)

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 4, 2010

Food safety reasons? In that case it is far better to use tin plating, food safe traditional solution, and last but not least it is tarnish free. Hope it helps and good luck!

Goran Budija- Zagreb,Croatia

February 6, 2010

(to help readers better understand the Q&A's)

An oxide finish instantly forms on stainless steel which makes robust plating difficult or impossible. The answer is usually to start the plating with a Wood's Nickel Strike or other striking solution which includes a very high concentration of acid (to dissolve the oxide) and a low concentration of nickel, such that a thin layer of nickel replaces the oxide.

Q. I tried Goran's (old German handbook) formula and by golly goodness it worked, except I used a silver anode. And I still don't know what activating stainless steel means.

David Castillo- Abilene, Texas, USA

April 11, 2010

|

Q. This is not about silver plating, but it does involve Goran's other solution. I tried the gold plating version and it works pretty good for safe homemade solution ... but it only worked if I plated for the first couple of minutes then it started plating a rose gold color. What is happening? Do I have contaminated gold or gold solution? David Castillo [returning]- Abilene, Texas, USA May 12, 2010 A. Hi David. Yes, the solution is probably contaminated with copper. We have many threads about gold plating, please continue this discussion on one of them. Regards,  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. |

April 9, 2011

Dear Sir,

I have a small factory making religious silver icons from pure silver 999, I also have a line of copper icons (small and large) and I am looking for a simple silver plating solution.

I was wondering if I can use single silver powder with a stainless steel anode, and if yes, what is the solution composition.

Thank You.

business owner - Bethlehem, Palestine

Hello, cousin Elias.

As you see, we have appended your question to a thread that may answer it for you. While we greatly appreciate Goran's effort to find a simple cyanide-free silver plating solution for us, it appears to me that a truly satisfactory generic one doesn't actually exist. Rather, you need to purchase a proprietary. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 11, 2011

December 31, 2016

Q. I am starting a small jewelry making business and want to be careful about the silver components that I use for my pieces. Any suggestions on what to look for in silver plate and/alloy metals and what to steer clear of that could be compromising to a person's health?

V. Milner- Decatur, Georgia USA

A. Hi V.

There might be a jewelry making course at a community college, night school, etc., that covers the topic.

Your question involves both the processes that the people fabricating the jewelry expose themselves to as well as the safety of the final product for the consumer. But, for example, cyanide silver plating is very dangerous for operators but poses no danger at all to the jewelry wearers, whereas nickel plating poses far less danger to the maker of the jewelry, but many wearers will be terribly allergic.

If you ask a more specific question, I'm sure our readers can answer, but "Safety in jewelry manufacturing and materials" seems to me to be too broad and multi-faceted for a forum "answer".

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello all,

I am a jeweler who occasionally needs to plate silver and gold at my home workshop. I have used cyanide based solutions in the past and really would like to switch to cyanide free plating. My main objection is that it is hard not to contaminate the work area with cyanide. I wonder if anyone tried Cohler EarthCoat or Clean Earth Plating Solutions in gold and silver and maybe has some pictures of the final products? Also, what is your general feedback on the quality of plating with these solutions. I heard mixed reviews.

Your feedback is much appreciated!! Thanks a lot!

- Ocean City, New Jersey

September 21, 2020

A. Hi Maria. This is one of many long threads on this site about non-cyanide silver plating. Some of the others are: Thread 0434, thread 26076, and thread 29629.

Pictures are welcome if anyone submits them, and the artists are welcome to say what plating solution they used, just as photographic magazines have always welcomed posting of what camera, filter, and film were used. But, sorry, for a number of time-proven reasons, we can't post suggestions, testimonials, or comparisons of brands or sources (why?). Apologies.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

September 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread