-----

Black Oxide on Brass

Q. I am wanting to anodize brass so it will turn dark and look like iron to use on model horse drawn vehicles. Can somebody please help me with instructions on how to do this?

Thanks,

Ellie Travers- Martinsville, Indiana, USA

2000

A. Sorry, Ellie, I've never heard of anodizing brass. I would be surprised if it were possible. I think what you want to do is blacken the brass. This is done with formulations that include arsenic, sulfides, etc. You should find some formulas and general instructions in the Metal Finishing Guidebook editions up to about 2005 (newer editions may lack a chapter on this). Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2000

Q. Sir,

We are in need of black oxidation process, for small brass screw. Please advice best method in step by step and chemical ratio to be used.

Please do reply at the earliest.

Bosco [last name deleted for privacy by Editor]- Coimbatore, India

2001

A. Hi cousin Bosco,

There are many different ways to blacken brass screws, and I don't think any one of them is "best" except in response to a specific list of what issues are most important to you. Did you get a chance to try the formulas and guidance in the book that I referred the previous visitor to?

The following threads may also help you --

Letter 19190, "Ebonol C blackening problems / Blackening candlesticks"

Letter 1198, "How to Darken Copper, Brass or Bronze".

This forum works well at pointing readers towards good references, and at answering highly specific questions where the answer is shorter than the question; but when you need step-by-step tutoring, you must refer to books because people won'tt compose and post those 13 pages of instructions in the book I mentioned :-)

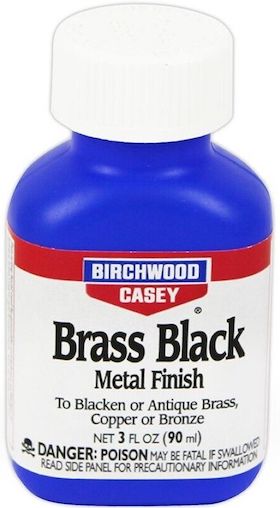

But the best brightening formulas are proprietary, not generic, and are the result of lifetimes of development effort; no one will give those to you. Rather, you buy those proprietaries, such as Ebonol C, from a local plating process distributor.

Best of luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I would like to know if anyone out there knows the proper process for black oxide on brass. Some people call it brown oxide but this is not true. I have learned that a process exists that you clean and activate the brass and then proceed to oxide. This does not make sense to me. Brass with all of the alloys that it contains would need a copper plate prior to oxidation to allow proper oxidation. Please advise!

Donal Hochstaetterplating shop - Kansas City, Kansas, USA

2004

A. Dear Donald,

There are various methods and sequences for coloring copper and copper alloys. There are also proprietary solutions that you can contact any of the supporting chemical suppliers for. One non-proprietary formulation uses copper sulphate ⇦ on eBay or Amazon [affil link] and sodium thiosulphate ⇦ on eBay or Amazon [affil link] at 1 and 2 oz./gal respectively. Note that the parts may need to be lacquered to retain finish. Hope that provides some help.

Best of Luck.

Ira Donovan, M.S.F.Kansas City, Missouri

2004

A. You can use 200 gm copper carbonate ⇦ on eBay or Amazon [affil link] /1 lit ammonia ⇦ on eBay or Amazon [affil link] solution. Very effective but very bad smelling solution. Work outside, use rubber rubber gloves ⇦ on eBay or Amazon [affil link] , protect your eyes!

Good luck!

Goran Budija- Cerovski vrh Croatia

2004

A. If able take to plating shop and have them deposit a cyanide copper coating of approximately 30 microns. Take it home, a light rub under water with 00 grade 00 steel wool ⇦ on eBay or Amazon [affil link] then immerse in solution of lime sulfur & unchlorinated water at 80 mls per liter. Agitation is needed to obtain an even finish whether you jiggle the object or use a pump to move the solution around do not touch the object until it has dried. The most consistent process I have found for a good result is to rinse in clean cold water then hang free in an oven to dry. Compressed air or hot water are not good as they affect the surface finish. Very lightly rub dusty dry surface with dry steel wool and lacquer.

Dave ColemanElectroplater/metal polisher - Gordonvale, Qld, Australia

2004

A. Yes, you are correct that per MIL-F-495 a copper alloyed part should be copper flashed prior to processing, chem. black. Also as mentioned above, a Cupric Carbonate solution will provide a black color directly to the brass -- but this is not commonly called "black oxide" as the Mil-495 process is referred to.

Bill Grayson- San Jose, California

2004

A. I had a similar problem with brass--a black oxide coating that was very stubborn. Brasso wouldn't tackle it, but I stumbled on a solution quite by accident.

I'd read in an eBay forum a few weeks ago someone praising a product called Shower Power. Well I didn't have any of that and I didn't feel particularly compelled to order it online; however, I did have some "Kaboom" shower cleaner. I would bet "Purple Power" would also work, but I have not tried it. I let my parts soak in an ultrasonic cleaner containing a dilution of the shower cleaner in water with a small amount of ammonium cleaner added. I'm not sure using ultrasound is even necessary--it's more a chemical reaction, but the ultrasound did help dislodge grime and oils. Five minutes later, the black oxide had converted to a red (or more of a pink) oxide.

While the black oxide would not come off with Brasso but the red oxide was very easily removed using Brasso, revealing nice shiny brass. I sprayed and rubbed the parts down one final time with undiluted shower cleaner to get rid of the petroleum residue left by the Brasso, and once dry, the brass was ready for several coats of polyurethane (the parts are decorative for indoor use).

Of course, if the brass is already coated with polyurethane, you'll need to strip that off before trying anything.

Hope this helps.

- Cary, North Carolina

March 10, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread