-----

Anodizing of stainless steel

Quickstart: Anodizing of stainless steel is an electrochemical process which generates a thin oxide coating on the stainless, producing partial wavelength (rainbow) interference coloration.

But it is important to note that although it's called anodizing it has almost nothing in common with the anodizing of aluminum. While anodizing aluminum greatly increases it's hardness, wear resistance and electrical resistance, and allows absorption of dye, do not expect this from anodizing of stainless steel.

Q. I keep seeing requests for anodizing stainless steel. Is there a process for doing that?

I have been in the business for many years and have never heard of it.

job shop - Lynchburg, Virginia

2003

A. Yes, it can be done. It does not have quite the usefulness that aluminum anodizing has. Two vendors at this site have processes for it. Prismatic Stainless Steel [from B&M Finishers, a finishing.com supporting advertiser] and another that I cannot remember; you can use the search engine [Ed. note: the other vendor was Russamer Lab, and Anna responds below].

James Watts- Navarre, Florida

A. adv.

Yes, we can anodize stainless steel to different colors, including black.

However in comparison to titanium anodizing, stainless steel colors are not so durable ⇩ and require some type of protective coating to become durable.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

Ed. update 2012: Anna updates this posting below, noting that she has now achieved durable colors.

A. Both Prismatic Stainless Steel [from B&M Finishers, a finishing.com supporting advertiser] and Russamer Lab [a finishing.com supporting advertiser] say they can offer it in colors. But the term "anodizing", while literally accurate because it is a process involving applying anodic current to the parts, can also be misleading because the process is radically different from aluminum anodizing, which is dyeable and thus offers a very wide range of saturated colors. The color of anodized stainless steel is diffraction coloration like that of titanium anodizing, carnival glass, and droplets of oil in a puddle. Further, when we see colorized stainless steel ⇨

usually the stainless itself was not colorized, but a titanium oxide coating has been applied to it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. You can also treat stainless steel with IVD - ion vapour deposition - to give an aluminium coating. You can then anodise it in the same way as aluminium.

Andrew Pridmore- Gillingham, Kent, UK

December 10, 2008

Q. In the house we bought 2 years ago, I have a 23 year old Thermador Cook n Vent cooktop with 4 gas burners and an electric griddle. It is stainless steel - 18 gauge, # 4 brush, grade 304 (Thermador informs me). It works great, but I have never been a fan of how stainless steel looks in a kitchen. I would like it to either take on the finish appearance of brass or nickel or an enamel-like appearance of white or black. Perhaps other colors. Perhaps other types of finishes I haven't thought of. Is this feasible? Is doing it, if it can be done, affordable? If yes to these questions, is there a company who could do this for me in New England?

Thank you so much for your attention to these questions. I am fascinated by this web site!

- Concord, Massachusetts

September 13, 2010

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Cook 'N Vent parts on eBay affil links

A. Hi, Barbara

Brass plating is probably not practical for a cooktop because brass tarnishes very quickly even at room temperature if not protected with a lacquer, and lacquer/clearcoats may not suit a cooktop. Nickel plating is certainly possible, but getting good adhesion onto stainless steel special pretreatments, so not all plating shops will plate onto stainless steel. Porcelain enameling in black, white, or colors is probably what you want; this finish is closer to melted glass on the surface than paint -- very high temperatures are involved. Sorry, I don't know offhand who offers porcelain enameling, but hopefully it was a little help to clarify what finish you might be looking for. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Ted - Thanks very much for your response. Will research it from your advice. If I make progress and think what I learn could be helpful, will pass it along to you! Barbara

Ted - Thanks very much for your response. Will research it from your advice. If I make progress and think what I learn could be helpful, will pass it along to you! Barbara

- Concord, Massachusetts

Q. Seeking care and cleaning/maintenance instructions for anodized stainless steel. Can any of the experienced industry contributors offer some simple care, chemicals to avoid?

Specific application: Pushbutton switch, switch has 200k life cycles expected...but will the anodized finish meet the life cycles with normal human touch or will it fade, chip or wear long before the electro-mechanical properties of the switch?

- Minneapolis, Minnesota, USA

December 1, 2011

Q. Can 316 Stainless Steel be anodized a Gold color? Does it create an Oxide layer like when anodizing titanium? If so, do you know what process is involved, for example, does it need to be acid treated first, etc?

Joell CruzMedical Device Technologist - Palm Beach Gardens, Florida

December 6, 2011

A. Yes, stainless steel can be anodized in various colors, including gold

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

Q. Thank you for your reply. Does the anodizing of stainless steel create an oxide layer like with anodizing titanium? This is the biggest question I am trying to find an answer to.

Thank you

- Palm Beach Gardens, Florida

A. Hi Joell. Yes, the color of anodized stainless steel is caused by interference as light waves bounce off of the stainless steel and off of the oxide surface. While you can certainly attempt the process yourself, at this point I don't think there is a wealth of public information on operating parameters -- it is still largely proprietary.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

adv.

I want to emphasize that a long time ago (2003) I posted that our stainless anodizing was not durable in comparison to titanium anodizing (see my first posting in this discussion). It is not true anymore - we have developed stainless coating that provides the same (or similar) range of colors as titanium anodizing (plus black), and the colors are perfectly durable. We have installed this technological process at a surgical instruments repair company.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

Q. I want to know if the SS trim from a classic car can be colored even if the type of SS is not known.

Thanks.

customs - Parish, New York USA

August 16, 2012

A. Hi Mark. There are probably other ways to color the trim than anodizing (chrome-look paint, for example), but you might contact Prismatic Stainless Steel [from B&M Finishers, a finishing.com supporting advertiser] and Russamer to see what they say. There are a lot of threads here, and they may not stumble back onto this one soon :-)

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Anodizing Aluminum and Stainless Steel Together: Can It Be Done?

Q. I have a Japanese made fishing reel I wish to re-anodize all black. It has a stainless steel component held in place by stainless steel rivets. I wish to re-anodize the whole thing without drilling out the rivets and removing the ss component because I can't find anyone competent enough to redo the rivets in the same quality as the manufacturer.

Can the aluminum and stainless be anodized together?

I also see mixed answers about anodizing stainless steel alone; some say it corrodes, others say it can be done. Can anyone give an authoritative answer on this?

Thanks!

- Yucaipa, California, USA

November 9, 2013

A. Hi Adam. As a practical matter, forget about anodizing your fishing reel as an assembly. Although almost nothing is utterly impossible, the processes for anodizing stainless steel and aluminum are radically different and each process is likely to destroy the other material unless it was flawlessly masked, which is highly improbable. Perhaps you can drill out the rivets and replace them with screws, either tapping the aluminum or using nuts.

As for whether anodized stainless steel corrodes ...

"Nothing lasts forever but the earth and sky" -- Kansas, 'Dust In The Wind'

... but anodized stainless steel has been successfully used for medical equipment, wall panels, and some other purposes. In your case, however, the stainless does not need to be anodized anyway. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. I want anodising on carbon steel or stainless steel fasteners. Is it possible ?

Paresh jadavaniKundan - Mumbai, Maharashtra, India

April 18, 2014

A. Hi Paresh. Anodizing of stainless steel is certainly possible as you read in this thread. As for steel, it is not a commercial practice, but may be possible: please see thread 37471, "Can plain carbon steel be anodized?"

But please describe what it is that you wish to accomplish, because words like "anodizing" may lead to misunderstanding because anodized steel, stainless steel, titanium, and aluminum have almost nothing in common ... people may see anodized aluminum and say to themself, "yes, that's what I want for my stainless", and find themself totally misled :-(

Thanks!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Is it possible to anodize stainless steel brake rotors for a motorcycle? Will the process of braking wear the color? For the record, I want to anodize the two front brake rotors and the one rear rotor of a Harley Davidson sportster. Thank you.

Robert CluesmanFilmmaker - New York, NY, USA

July 29, 2016

A. Sorry, but the color only results when the coating is limited to a partial wavelength thickness; it is therefore not appropriate for a wear application like a brake rotor.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I need to remove some anodizing from a stainless steel part. Is that possible without damaging any pieces not anodized? Thanks for your help.

Kenneth Colemerefabrication - San Antonio, Texas USA

February 1, 2017

Q. I have 3 different size ball gauges (21 mm, 25 mm, 28 mm) used for what we refer to as a ball drop test to check for the ID to be in spec. (plastics manufacturing plant)? I've currently got a good amount of each of these ball gauges, all solid stainless steel, and we are constantly having the balls mixed up by the operators. I am looking into having these finished in a way that they would be easily distinguishable. I would need something durable, as these are used upwards of 600 times a day. I can't risk any type of coating that would possibly leave debris of any sort in the part. Also, they're dropped into a metal trough from about 3 feet high. Any suggestions?

Jordan Hamblen- Gallatin, Tennessee, USA

August 8, 2017

Q. Can I do anodizing on stainless steel to weld it for polymer by hot press bonding ... thanks.

Mahmood M. Hamzah- madaen, baghdad, iraq

October 14, 2017

A. Mahmood,

When questions get added to old threads like this, I don't know how clear it is that the answer probably lies in the replies above.

In this case, see Ted Mooney's reply to Paresh, where he says "Why do you ask? What precisely do you want?"

You say anodizing, and then you say welding, and then you say hot press bonding, all of which are different things. You also mention polymer, which to me means plastic materials. I really don't know what your actual end goal is.

Since anodizing is not normally done on stainless, I think people need to focus less on naming a process they want and more on describing the surface they want to produce.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

![]() Hi Ray. That was excellent advice that people "focus less on naming a process they want and more on describing the surface they want to produce".

Hi Ray. That was excellent advice that people "focus less on naming a process they want and more on describing the surface they want to produce".

I think Mahmood is making a component from stainless steel and polymer, and is looking for some process to do on the stainless steel (possibly anodizing) which will help the polymer (which is attached to it by hot press bonding) adhere better. My guess is that "welding" was just an unfortunately chosen translation and he actually meant "bonding".

Most of the time, including this time, the questions are too brief; if a question is shorter than the answer they want, it's probably an abstract question which is difficult/impossible to answer properly :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi,

I have a few pieces of 316Ti, and would like to combine it with some other material to create a pattern forge weld (Damascus), layering a piece of D6 on both sides with it, so the D6 becomes the core.

If I use either one of the following material (316, 3i6L or 310 with similar expansion coefficient to the 316Ti) as the second material with the 316Ti, Will it give me a significant contrast when anodized?

Or do you propose an alternative material?

Your insight will be highly appreciated.

Hobbyist Knife Maker - Centurion, South Africa

October 18, 2017

A. Hi Hannes. 316Ti is only about 5 parts per thousand Titanium so (without any actual experience with it) I wouldn't expect it to be significantly different than other 316 stainless steels, but it would be nice if a reader actually did have experience with it. I also have no experience in knife making, but understand that 3XX is not used for blades since it can't be hardened.

But I don't think anodizing of stainless steel is involved in any way with your choices. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I am wanting to develop a front skid plate for my vehicle. Aluminum is too soft in that if it hit the ground or a rock it dents too easily. I would like to make the skid plate out of stainless steel, but I am really wanting it to be black. This skid plate will undoubtedly get abused ... scratched, gouged, road grime, etc.

I am wondering if anodizing this stainless steel skid plate black, will it stay black under this type of abuse?

- Portland, Oregon USA

January 29, 2018

A. Hi Karl. Any coating, including stainless steel anodizing, will quickly scratch off. I'd suggest black powder coating or paint because it's easy to touch up.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Hi Karl,

If this is made from stainless steel 400-series, like 420 or similar (surgical steel), it is possible to anodize it black and then special final treat it, so the black becomes as durable as hard anodized aluminum. We are working on similar treatment for 300-stainless steel, but not lucky yet.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

A. Hi Anna. I'm going to have to somewhat disagree on this one based on the application.

When you are off-roading and you misjudge the size of boulders vs. your road clearance, or you have to get over it anyway, skid plates (optional equipment on most off-road vehicles), allow the whole weight of the car to 'skid' or scrape across the boulders, riding on that plate instead of ripping out wiring, brake lines and other under-body equipment. As Karl says, the skid plate will get gouged, maybe 1/16" of an inch, maybe more -- not lightly scratched; I don't think any finish at all can maintain its color after such gouging :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

|

Q. I have powder coated (black) steel posts that set on columns (5) on my house. The posts are welded onto flat powder coated black plates. The installer used large stainless steel bolts to attach to the columns. - LAFAYETTE, Indiana, USA July 11, 2018 A. Hi Tammy. If you can find black stainless steel bolts, whether anodized or blackened in a different fashion, they'd probably be okay. But getting a shop to anodize a handful of bolts might be very expensive. There are PVC or nylon caps or covers for nuts & bolts ⇨ Regards,  Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance.

- Lafayette, Indiana USA |

Q. I'm producing a stainless steel guitar pick, and I would like a shiny red finish (presumably shiny from polishing the pick before processing for color). I realize that due to use, virtually any process will wear off, but it only had to look good for a short time. What would be your recommendation please? Thank you.

MJ Klein- Hukou township, Hsinch county, Taiwan

September 25, 2018

A. TiCN with PVD technique can give copper-ish (antique like) colour. Actual colour depends on Ti/C/N composition and other deposition conditions. Being a hard coating it could last for some reasonable time depending on usage. But there are many practical issues like pre cleaning, handling & manipulation of the wire in a vacuum chamber, quantity, etc.

H.R. PrabhkaraBangalore Plasmatek - Bangalore, Karnatka, India

Ed. note: Prabhkara has a great idea, but he also offers a caution to be realistic. Nobody will let dirty picks into their multi-million dollar vacuum processing machine for fear of contamination, nor will they be able to affordably fire it up for a handful of picks. You'd probably need batches of at least several hundred or thousand at a time.

![]() Thank you for your reply.

Thank you for your reply.

- Hukou Township, Hsinchu County, Taiwan

A. If hard temper aluminum would work, it can be anodized and dyed to any color in the rainbow, and the anodizing would be fairly durable.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

Ed. note: Great point Jeffrey; aluminum picks may be more practical than stainless steel.

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. What is the electrochemical process of anodizing stainless steel to Golden color?

Sumit PoddarBICYCLES - Ludhian, Punjab, India

October 27, 2018

A. Hi Sumit.

If you're doing a couple of custom bicycles, anodizing might be the way -- what grade of stainless do you want to anodize?

But if this is a production situation, are you sure that your interest is in anodizing stainless steel in a golden color? I think depositing titanium nitride on it in a PVD chamber is more common, more robust, cheaper, and offers closer to a true gold look too :-)

Get back to us please. Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

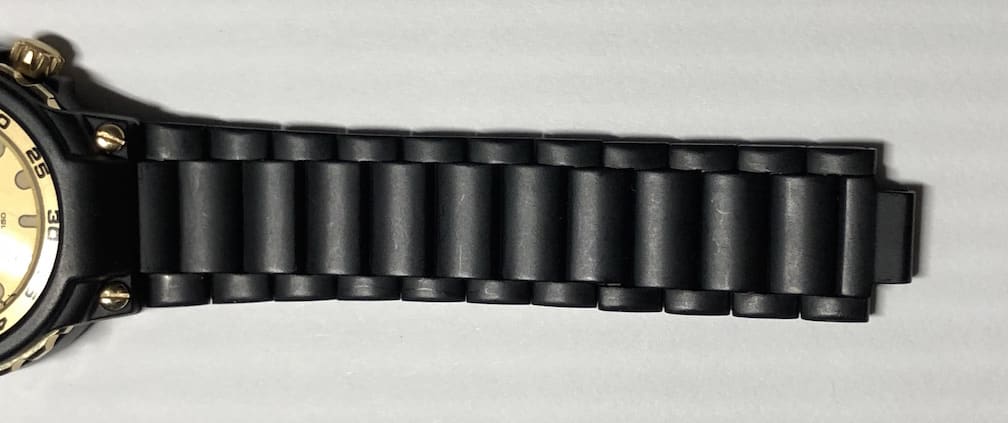

Q. Hello... I have a black "metal" Seiko watch band which I need a clasp for. If I buy a stainless steel clasp, can it be anodized to black to match the band?

Drinker Durrance Graphics - Carbondale, Colorado USA

November 29, 2018

A. Hi Sue. Surely it can be done, but the issue will be the non-affordability of asking a shop to do a one-off job like this. A faucet washer is a 50¢ item but getting a plumber to replace it is at least a $150 job. Similarly, a plating shop can anodize thousands of small items at a time at a unit cost of say 50¢, but doing one would be liable to cost $100.

If you can find a jeweler specializing in Seiko watches s/he can probably find a black clasp for you, and I see a number of styles of black Seiko clasps on eBay ⇦ on eBay or Amazon [affil link] , but I'd guess that the originals were probably PVD coated for durability rather than anodized.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thanks! I will try all other possible avenues, but rather than holding it together with a safety pin, I might not have any other options.

Thanks! I will try all other possible avenues, but rather than holding it together with a safety pin, I might not have any other options.

Drinker Durrance Graphics - Carbondale, Colorado USA

Ed. note: Now a black safety pin, that we can probably find :-)

Q. This question is for everyone on this board but I hope to get an answer from both Ted Mooney and Anna Berkovich.

I am in Michigan, looking for colorized stainless steel with "mirror finish" specifically, blue, green, purple, red and gold colors ⇨

I would like to include this material and finishes on metal art/sculpture pieces.

What are my options? Anodizing or another process? (do not want to use aluminum - it must be stainless steel)

Do you know any places I can buy samples from?

Thank you

Metal Artist - Lansing, Michigan

March 1, 2019

A. Hi Rich. I'll alert Anna that you'd like her input, and hopefully other readers will chime in with technical comments. I am not aware of techniques other than anodizing or PVD application of titanium, but you might search the site with the term "inco process stainless", and then use the same term on google.

Sorry, but we can't suggest sourcing or brands beyond Prismatic Stainless Steel [from B&M Finishers, a finishing.com supporting advertiser] and Russamer Lab [a finishing.com supporting advertiser] (why?)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. It's going to be real difficult to have your stainless steel art anodized after you are done building it.

I suggest using translucent metal dyes instead ⇨

- Managua Nicaragua

Q. Will anodizing 316 to a color/tint increase emissivity of the material?

Bruce Schram- Menomonee Falls, Wisconsin USA

August 7, 2019

A. Bruce,

Anodizing is pretty rare for stainless. Not sure what you're trying to accomplish.

Nor do I come across that word too often, so let's check what property it refers to: "The emissivity of the surface of a material is its effectiveness in emitting energy as thermal radiation."

I'm going to go with, I rather doubt that anodizing would have any non-negligible effect on the emissivity of 316 stainless.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

Q. Thanks Ray for the response. My customer requires 316 stainless enclosure for corrosion resistance in a food preparation application. The watts dissipated in both a brushed 316 enclosure (acceptable) and a painted 316 enclosure (unacceptable) have the same watt dissipation at the start. Conduction and convection properties remain the same for both. Under constant load and stabilized temperatures, the painted 316 enclosure will stabilize at a 15-20 °C lower temperature than the brushed 316. Since all other factors are the same, I can only assume that it is the result of the change in emissivity between 316 stainless (about 0.28 @ 24 °C) and the paint (about 0.91 @ 27 °C). Would anodized 316 provide the same emissivity of the painted enclosure and would it be as durable?

Bruce Schram [returning]- Menomonee Falls, Wisconsin USA

Bruce,

So what you're saying is the layer of paint is acting as a thermal barrier or insulator, keeping the heat in too much?

Again, my educated guess is that an anodized surface would not be an appreciable thermal barrier. But again, I'm not sure what you're trying to accomplish. As in, what's wrong with just a bare stainless steel surface, brushed, polished, or whatever?

Besides that, if you need to increase heat dissipation, you could build cooling fins into the structure.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

A. Hi Bruce. Generally anodizing roughens a surface and increases its emissivity. In the case of aluminum, the emissivity increase due to anodizing is huge. I suspect that Ray is correct that it will be inconsequential in the case of anodized stainless steel, but don't know where to find such data.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello,

I'm looking to produce 316 stainless steel jewelry. Is anodized coating on stainless steel (gold .8 microns or black) more or less durable than PVD?

People Preach - San Francisco, California

October 13, 2019

A. Hi. My guess is you'll be happier with PVD coatings than anodizing if you want gold color. It will be cheaper, more durable, and more attractive.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Ed. note: The forum is most useable when discussions are organized by topic so readers can easily find the most relevant discussions. So we moved Mel's follow up questions about gold plating, titanium nitride, etc., to thread 34692 :-)

Q. Hello, can I anodize stainless steel 304 bolts with gold colour? If I can, what method can I use for my project at home? Which one is more costly between PVD and anodizing for stainless steel?

Ameer Asyraf- Johor Malaysia

October 1, 2020

A. Hi Ameer. I'm sorry that there are so many questions & answers about anodizing and coloring of stainless steel on this site that it can be time-consuming to find them :-)

Prismatic Stainless Steel [from B&M Finishers, a finishing.com supporting advertiser] and Russamer Lab [a finishing.com supporting advertiser], probably among others, offer proprietary solutions. For your "home project", Goran Budija offers one example of the chemical mix and process conditions in thread 33236, although I wouldn't use toxic, carcinogenic chromic acid in my home. You can search the web or scholar.google.com for "Inco process" or "Inco coloring" for more detail on this.

The issue with PVD is that you need a specialized vacuum chamber which more than a a thousand times as costly as most hobbyists would entertain.

Without knowing why you want to do what you want to do, how big the bolts are, how many, where they will be used, exactly what "tone" of gold you are looking for, etc., it is hard to say whether there might be a third and better alternative. But I'd suggest the online pamphlet

"Colouring Stainless Steel" from Euro Inox as a great intro. And Marvin Sevilla's idea of translucent metal dyes might be a great hobbyist idea. Good luck.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Try 50 gms phosphoric acid/ 1 lit water solution, 20 minutes immersion, boiling solution (according to patent US2521580A). Hope it helps and good luck!

Goran Budija- Zagreb Croatia

Q. So basically the thread is saying you cannot alodine stainless steel? or am I incorrect? But it seems Alodine (not anodizing) cannot be performed on stainless, judging by careful reading of all Q&As ... trying to see the clearest reply to that question.

Anthony 'OldMotorBikeMan' O'Haracustomiser of many useless & sometimes useful things - Beeliar, west australia

February 27, 2022

A. Hi Anthony. Nobody talked about Alodine on this thread. As Ray Kremer suggests, it's probably best to talk about what we are actually trying to achieve with a finish rather than focus on its name because that can lead us down the rabbit hole :-)

Alodine is a Henkel trademark for a chromate conversion coating on aluminum. Stainless steel will not acquire a chromate conversion coating on it ... so I will say "no, you cannot Alodine stainless steel".

But others have said on other threads, roughly, "I have an aluminum component which we put stainless steel threaded inserts into, and then we successfully Alodined it -- by which they mean the Alodine didn't/doesn't ruin the stainless steel portion like aluminum anodizing would do.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread