-----

How to Rust Steel On Purpose

Q. Hi we are Aussies living in Fiji. I am creating a beautiful garden and I want to fill it with rustic iron garden ornaments and decor . Today we are working on a gate made out of corrugated tin and old timber. I can't find nice old rusty iron without the damage and dents being too extensive so I want to oxidise it my self. I note you mention spraying vinegar

⇦in bulk on

eBay

or

Amazon [affil link] , which I will try. Anything else though you could advise to produce a lovely reddish brown result. I intend on rusting other iron artifacts that I come across too so is it one method suits all or some work on cast iron better than tin and so on.

thanks

lee

hobbyist - Fiji

June 3, 2009

Q. I received a thin, flat steel weld cut-out of a cat (about 2' x 3') as a gift recently. The steel had not been protected and there is a patina of rust on it. I had considered having it sandblasted to bare metal and then coated at an auto body shop. But the rust is a beautiful rich brown and I'd rather keep it as is. Is there any way to fix/preserve the rust so that it does not continue to consume and eventually destroy the piece? I wonder if Waterlox, a coating and sealer for wood would work? Some other costing? I'd prefer a flat finish so the rust looks as natural as possible... Thanks very much

Kent Reicherthobbyist - Philly, Pennsylvania

July 28, 2009

October 30, 2009

Q. In building our new home, my son has decided on some unique features for his room. He is quite techno savvy, but we have encountered some problems.

First of all he designed a barn door for his entry door and closet. However, he would like to back the entry door with a steel plate which has an antique rusty look about it. We have some steel tags and tried different methods of corroding them, but nothing seems to have the desired effect. We only get small results that seem to mostly wash off. We are either using the wrong substances or wrong proportions.

We need to :

1. Find something that will rust steel.

2 find the quickest way to stop the oxidation when it gets to the point we like.

3. find what we can use to seal the steel with after the corrosion is finished so it doesn't rub off onto clothing.

We wold appreciate any help you can give us.

- Fort Collins, Colorado

November 10, 2009

A. Achill Island is an Island off the west coast of Ireland in the Atlantic.

I camp there every year.

Every year, the side of the car facing the wind off the coast gets rusted brake disks within a day or two.

Similar to this:

Therefore: Sandy Salt + Moisture = Rust

Works for me...no products, just elbow grease.

Cheers

- Achill Island, Ireland

January 12, 2010

A. I'm an artist and I love drawing on rusted steel.

To make the steel rust simply use Hydrochloric acid or Ammonia water.

It will start rusting in few hours.

If you need to wipe off the rust you can use Hydrochloric acid again,

and rinse the piece with water.

To prevent the steel from rusting, brush a thin coat of oil.

You can see what I'm talking about here:

If you like my site... share it! ;)

Olivier de Géa- Paris France

----

Ed. note: WOW!! That sketch absolutely takes my breath away, Olivier.

For anyone unable to read the watermark, Olivier's site is www.olivierdegea.com.

A. I am an artist who works with steel and like many of you have the need to have a rich rusty look but where it will not rub off.

On pieces that will be indoors...I have used distilled vinegar and water putting on many layers until I reach the desired look. I then coat it with several coats of satin polyurethane.

Hope that helps also.

Ali

Ali Gallo- Edgewood, New Mexico, USA

March 28, 2010

Q. Hi my name is Bob I was wondering if anyone could help . I am making coffee tables out of hot roll steel. I would like to keep it a hot roll finish and do not know what to do about the areas were I dressed the welds if there is some way I could create mill scale in those areas only. Thanks

Bob BlakeHobbyist - Reno, Nevada

April 19, 2010

A. Like others, I am also an artist who specializes in custom gates, trellises, wall and yard art. Many of my pieces are chemically rusted.

What I have found that works best is to use 1/2c root killer (copper sulphate) and mix with 2 cups muriatic acid until dissolved. Pour into gallon jug and fill remainder with water.

Spray this onto your clean metal (the oil must be removed) and then either immediately, or whenever, you can spray with a diluted bleach

⇦ bleach/sodium hypochlorite in bulk on

eBay

or

Amazon [affil link]

(can be chlorine) solution.

You will instantly see the reaction of the two chemicals and can tweak the look with misting of water. Or, if you live in a humid climate, you can forgo the bleach spray.

Steve

irongardenstudio.com - Tucson, Arizona

August 3, 2010

A. In response to rusting metal. I do much work in the Telluride area and have rusted barn tin for many custom homes. It is very simple. I mix 50/50 Muriatic acid and water. Mop it on with an old rag mop, let sit over night, sometimes two nights, then rinse thoroughly. Many suggest cleaning the metal first for an even look, which is true, but I find the uneven rusting brings out a more natural patina in various shades. Evenly rusted metal looks fake to me, as do many of the metal roofs in Telluride. if I want to expedite the rusting after the initial application, I just spray salt water made with sea-salt over several days. Our ever-changing weather always ensures the chemicals are washed off fairly soon.

James BatesApex Design - Montrose Colorado

August 31, 2010

A. Hello, I am a master German painter. Here is how you rust most any metal and then prevent it from rusting further and also make a very nice finish and bring out some natural color from the rust:

1)Urinate into a clean spray bottle.(5 tablespoons of urine will do).

2) For every 5 tablespoons of Urine, pour twice that amount of hydrogen peroxide into the spray bottle.

You now have your magic solution.

3) Wipe whatever you are trying to rust with Xylol/Xylene

⇦ on

eBay

or

Amazon [affil link] to clean it and remove anything that might inhibit the oxidation process. Let the XYLENE dry completely.

4) Spray your magic solution generously onto the metal, let dry, repeat, let dry, repeat, etc... until you get the amount of rust you are looking for.

I generally spray it and leave it outside overnight. leave it out in the rain, snow, whatever. These are all good things.

5) When you have the amount of rust you want, wipe it down with a clean rag.

6) Spray it with lacquer. Two coats. Make sure it's a real lacquer that is a lacquer thinner base. M.L. Campbell pre-catalyzed lacquer works great or any other lacquer that is a true lacquer(not water-based!)

Note: You can use something else if you want(metal etch, muriatic acid, vinegar... but I use urine because I get a distinctive color in the end that looks better than these other methods.

Good luck!

- Gunnison, Colorado

Q. Hello guys! reading through this thread made me really inspired for an art project, my teacher took a summer course using rust applied/printed onto textiles. The art I'm working on now is with movement and aerodynamics, so such a metal/rust feeling is a perfect medium. well earlier I have been working with steel thread and sowing with it, great media to modify things with. I had an idea to sow onto a canvas (a textile) and then dump this into some sort of mixture that would make it rust and then make that rust go onto anything it's touching, such that it won't spread all over the canvas, only where its touching. Does anyone have any experience with doing something similar to this? Sorry for my english by the way, second language.

Jostein

- brussels, belgium

September 23, 2010

|

Q. Can you rust tin? kay rathmann- sioux city Iowa November 3, 2010 A1. No. A2. Hi, Kay. If you're asking people to devote some of their limited time to help a stranger, please invest more than 13 characters :-) When you say "tin", are you using slang, and actually mean steel sheet metal? Or do you really mean the element tin? Because, no, tin does not rust; in fact, nothing can rust except iron and iron products like steel because rust is iron oxide, which you cannot create without iron. Do you actually mean "Is it practical for me to deliberately and in controlled fashion make steel sheet metal rust for decorative applications?" If so, yes, and this thread and the previously referenced similar threads are all about doing that. Regards,  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. November 3, 2010 |

A. We have customers who want to seal rusty metal but need to rust it first. I was given a recipe for rusting metal that is safe and inexpensive.

Spray the metal with vinegar (any kind will do)

Then, immediately spray again with hydrogen peroxide. Use 2 different spray bottles or sprayers.

Let dry and repeat several times a day and within a few days you have rusty metal.

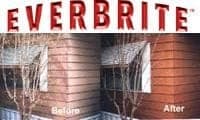

Everbrite will seal rusty metal and will allow the rust to show through. The metal must be completely dry and the loose rust removed for good adherence. There is a Satin finish available that many people prefer.

Everbrite Coatings

Rancho Cordova, California

November 30, 2010

A. Causing rust is easy...the fastest way I have found is pool chlorine or lemon oil, depending on the look you want.

Halting rust is also easy...I found a marine product at ACE Hardware called Ospho [adv: Ospho on

eBay or

Amazon [affil link]

. It is cheap and goes on like water and will completely stop rust. The process takes a while and some "blue" may appear but can be removed with light brushing. Best to let dry for 2-3 days until brushing.

- Lenoir, North Carolina

December 8, 2010

Q. Hello All, getting excited about finishing my first cuts of metal art with a rusted finish. I went and bought some hydrogen peroxide (I read on the web that will cause rust), that didn't work, I tried vinegar, that didn't do anything either.

What am I missing here? I took my metal piece, cleaned it, I even tried heating it. It is cold rolled steel, then I took sandpaper (about 150 grit) and rubbed the surface and tried both methods again - just tiny tiny rust spots.

Is there prep work to the metal that I should be doing that I might not be to get these pieces to rust? It shouldn't be this hard from what I am reading? HELP!

Why are my pieces not rusting?

- Independence, Oregon

December 17, 2010

A. Hi, Charlene. You might want to double check that your "cold rolled steel" isn't stainless steel. Is it very strongly magnetic?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

December 18, 2010

Q. It isn't stainless steel, it is cold rolled I verified from the person that cut it for me, it is thicker - about 12 gauge - but it can't be this hard. Everyone here makes it sound like their pieces rusted so easy? I used combo of vinegar and hydrogen peroxide last night, sprayed on in coats, woke up this morning with just one tiny little spot of color? This can't be that hard.....so off to the store to get some muriatic acid to try that - but I don't want cancerous rust, just the nice light rust color - ARGH!

Charlene Stovin [returning]- Independence, Oregon

December 18, 2010

A. I mixed bromine, a common hot tub sanitizer, with water in a spray bottle. then sprayed it directly onto my steel and I got big time instant rust so watch your amounts. no soaking overnight or anything like that, it is truly instant. make sure your area is well ventilated though as it can be strong smelling.

steve thomaswelder - fort collins, Colorado

February 20, 2011

Q. I checked this site a few weeks and decided to go ahead with making a rusted metal desk. We didn't want it to completely rust. We wanted it to have a pattern. The results turned out well, we soaked marine rope in bromine water and laid on the surface to create the pattern. We had considered putting peroxide on it when it was done to stop the rusting process but figured that varnishing it would be enough. We applied 10 coats of poly urethane just to be sure. But now that the desk has been installed the varnish seems to be chipping off, not because of misuse - we have been very careful with it but it seems like it is chipping off in the most rusted spots. Is it possible it is still rusting under the varnish? or is it because we didn't wipe those spots on the table off enough for the varnish to stick?

At this point would it be best to just clean these sections of excessive rust and re varnish? or is this going to be an ongoing issue and should we look into a product like Everbrite? or any other suggestions? Or is the only option to cover it in a thick epoxy finish like discussed in letter 12362?

Thanks!

- Kingston, Ontario, Canada

August 20, 2011

A. Finish For A Rusted Piece

Once a level of distressing plus oxidation are achieved, the finish can be preserved with 4 ought steel wool

⇦ on

eBay or

Amazon [affil link] and mineral spirits (or turpentine

⇦ on

eBay or

Amazon [affil link]

if cost no problem) and furniture-floor wax.

The idea is that the steel wool and mineral spirits take the rust deeper into the surface and the spirits redistribute the rust that the steel wool removes. The spirits gets rustier as the wool is repeatedly dipped in a small bucket of it. Rub the entire piece down two or three times with the increasingly rusty steel wool and spirits, let dry.

Use a rag to apply Johnson's floor wax, and other clean rags to buff it back off.

The resulting, low luster finish will last decades if not in the weather or near sea coast.

Work with rubber gloves, in a well ventilated area, away from a source of ignition.

Designer - Jackson, Mississippi, USA

January 23, 2012

July 31, 2012

A. Okay, rust is a popular finish here in the desert, and I've done numerous jobs that required fresh steel to look old. Here's what I do.

To rust galvanized, you first must get rid of the galvanizing --muriatic acid is the best thing for this. Whatever way you apply it, wear gloves, goggles, and a respirator (the cartridge kind NOT a dust mask!) If you don't have or can't afford a respirator, stay upwind and hold your breath, the fumes are nasty. Muriatic acid will also etch concrete, stone, and glass and will discolor wood, so cover these surfaces with plastic if you can't get far away from them. I only do this procedure outdoors in a spot where I don't want any plants to ever grow. The acid can be sprayed (although any metal parts in the

⇦ on

eBay or

Amazon [affil link]

will be sacrificed), wiped, brushed, or spotted onto the surface depending on your desired effect. Let it do it's thing; and when it's done fizzing, rinse the metal with plenty of water.

If you don't want to get toxic, you'll have to remove the galvanizing with a grinder or sander.

Now, to rust!

If you've already done the acid wash you're ready- works on any steel, btw. If not, degrease your metal some other way. A light sanding helps too --you want the metal to be as clean and receptive as possible.

Mix:

2 parts vinegar- any kind as long as its 5%

8 parts hydrogen peroxide

1 tsp salt per 18 oz. of mixture

You don't have to be a chemist- the exact proportions aren't critical.

Mix thoroughly.

This is best applied with a spray bottle or pump sprayer, but can be brushed on too. Keep in mind that the initial rust that forms is very delicate and easily removed if you brush too hard or have too much acidity in the mix. You should see a light coating of rust forming immediately. Keep at it; I usually do 5 to 6 applications minimum, letting each dry, rotating the piece while touching it as little as possible. Keep applying until you get the desired depth.

Go to bed. The next day you should have well-set rust.

To seal it, mix:

1 part OIL BASED polyurethane

1 part boiled linseed oil

1 part turpentine or mineral spirits

⇦ on

eBay

or

Amazon [affil link]

Rub it in well- until no excess sits on the surface. You'll be left with a semigloss sheen that will fade over time.

- Joshua Tree, California USA

![]() Hi, Guy. There have been many informative postings in this thread, which we greatly appreciate, but yours is just so complete. Thanks.

Hi, Guy. There have been many informative postings in this thread, which we greatly appreciate, but yours is just so complete. Thanks.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August 1, 2012

Q, A, or Comment on THIS thread -or- Start a NEW Thread