-----

Need to buy or design/build salt spray chamber

Q. I want to design and manufacture a Salt Spray Apparatus. However, I would like to know all the components needed to make the best test cabinet on the market. This will enable my company to serve the needs of all who are in need of the perfect cabinet.

Your help will be greatly appreciated.

Mike C [last name deleted for privacy by Editor]- Chandler, Arizona

2001

A. Hi, Mike.

I'd start by examining the newest salt spray cabinets from the existing suppliers and see in what ways, if any, they seem deficient to you. Then I would do a patent search because there are certain accessories or approaches you are prohibited from offering. Then I would check the ASTM corrosion tests to see what kind of specifications the cabinets you wish to design must meet.

I think you'll find letter 7583 interesting as the inquirer asked what factors are important in choosing a salt fog cabinet and several readers offered their answers. Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2001

A. First of all, take a look at what is already commercially available. There are a few major companies that already do very well in this market. You will have to have some sort of advantage over existing cabinets to convince people to buy from you. If you are not already intimately familiar with salt spray testing, I don't see how you could compete.

The cabinet must fully comply with ASTM B117. Good cabinets will also have the capability to run humidity testing, CASS testing, and perhaps even Kesternich testing. A top-of-the-line chamber must have controllable temperature, fog rates, and relative humidity. It should be able to do cyclic tests and be programmable for custom cyclic testing.

Make sure you understand what you are getting into before you invest a lot of money, time, and effort.

Good luck!

Tim Neveau

Rochester Hills, Michigan

2001

RFQ: We need to perform a salt spray test according to ASTM B117. Our customer is Boeing, where could we get a right to perform this test, what is the machine's price? How many days the machine should be delivered from ordered?

Hunter [last name deleted for privacy by Editor]operation manager - ShangHai, China

2004

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

RFQ: Need Salt Spray test cabinet that conforms to ASTM B117 standard.

At first glance our budget limits us to the 120 liter cabinets, but we would prefer a larger size if pricing is within our budget.

For delivery in Granby, Quebec, Canada

Automotive accessories manufacturer - Granby, Quebec, Canada

2005

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. How to design a salt spray chamber? I want to design a salt spray chamber for saline environment simulation at 35 °C. What should be the design?

Mallika Gope- NOIDA, U.P., INDIA

2006

A. Hi, Mallika. I'd certainly start with ASTM B117. And I'd suggest making it of fiberglass rather than steel. Best of luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2006

Q. I am looking to make a simple one time use salt spray cabinet to test circuit boards for corrosion. Kind of DIY project. The cabinet doesn't have to meet any standards or be commercial quality. Any ideas where to start besides ASTM B117. What simple household materials can I use (eg. hose nozzles). Anything will help.

Thanks,

- Milwaukee, Wisconsin, USA

2007

A. Hi, Ilya. If you just wish to accelerate the corrosion, with no standards to meet, just pour wet salt on the boards, leave them in the sun, and spritz when they get dry.

But if you seek repeatability, yet don't wish to buy a salt fog chamber, you might do a search for "CAMRI testing". This is a highly repeatable accelerated corrosion test that can be done with very little investment, and has been used by very reputable organizations including the International Zinc Association. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2007

A. Attached is a pic of a DIY chamber I built to test supplier hardware used on high end high performance windows and doors. Like most of your responders suggested I went to ASTM B117 to put together requirements for establishing the design intent.

Much of these products I test are used on or close to ocean front environment. Also I test samples from in-house painting and vinyl film laminating.

This unit which we invested about $500.00 has been operating about 6 months. In that time it has paid for itself about 10-fold. I can give details if requested.

Most suppliers I deal with are eager to make changes to correct issues I have found in their products.

I would be happy to share details of design and parts used.

Quality Control - Orlando Florida USA

July 8, 2014

Q. Thanks Tom, I am very interested in the build specs for your salt test chamber. How do we get a copy?

Brian Janowski- Marquette, Michigan, USA

July 16, 2014

A. I will work up the specs - mostly hand drawn and a parts list.

I'm only interested in refinements discovered by other builders and users. E.g., you may choose to use different materials and circuits that are a more efficient design than mine.

I will include some pics of tests results That caused actual changes in design and/or metals used in the assembly.

You should see something by end of next week.

Thanks for your interest

- Orlando Florida USA

July 17, 2014

July 24, 2014

A. Attached you should find parts lists and schematics of the chamber and pictures of the critical parts.

Schematic

Sketch

End view

Air brush

Air solenoid

Air source

Aspirator

Aspirator hook-up

Auxiliary outlets

Collar and water seal

Control panel

Hanging rack

Relay, breaker, solenoid

Rubbermaid cart

Tank ports

Tower with service loop

Salt Fog parts "partial list"

Digital Hydrometer 3.50 E bay

420 NM UV Light 30.00 E bay

110VAC digital prog. timer 7.25 E bay

100W silicone Pad heater 27.00 E bay

SS 8 Qtr. Pressure Cooker 50.00 E bay

Single burn hot plate 19.00 E bay

Thermostat with relay 14.00 E bay

PVC pie & caps 12.00 Lowes

Drain hose 2.50 Lowes

Drain port 3.50 Lowes

Aspirator ( air brush) 10.00 Harbor fright

PVC column and Base 12.00 Lowes

Glass 65.00 Tecnoglass

Plexi - top 50.00 Lowes

Control box and relays 100.00

Re. Glass - An aquarium will work - just be careful with heater pad (if used) e.g., thermal shock may crack the glass.

These parts were collected over a period of about 6 months. Some items purchased did not work well and replaced with the parts you see in this list. Look over the schematic and start shopping. Only the thermostat and timer from the control box are on this list. I'm sure you could get the rest of the relays and breakers on eBay or a surplus house of your choice.

Good luck and let me know how you've improved this design.

Thanks

TW

WIndoor inc - Orlando Florida USA

July 2014

![]() Great work Tom, and incredibly generous of you. Thanks for sharing.

Great work Tom, and incredibly generous of you. Thanks for sharing.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi all. I am really interested in building this salt spray chamber. I would be really thankful if someone could help me out with some tech-info. What is the use of aspirator in this design? Thanks a lot.

Klemen Grabnar- Slovenia

June 13, 2015

Q. I want to perform a salt spray test on diodes which has salt concentration 5% and duration will be of 48 hrs. Can anyone please suggest me how should I proceed if I want to make this salt spray chamber within range of specified conditions above so that I can also conduct similar tests in future? I am basically interested in developing chamber by myself. :)

Abhay Thakur- Mumbai, India

October 24, 2015

A. Hi Abhay. I would start by obtaining a copy of ASTM B117 or ISO 9227 since I'd assume that you would want the results of your 5% salt spray test to be similar to the results that others get when they conduct 5% salt spray tests, and you'll want to know what you have to do for your results to have validity in that regard.

After that, you might follow Tom West's explicit directions, or ask highly specific questions about them. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 2015

Q. Hello,

I am a mechanical engineering major working on my senior project. My group is to build a salt-fog chamber for our design course. I was wondering if there was a diagram or schematic showing how the electrical components were hooked up in the DIY salt-fog chamber made by Tom West in this thread?

- Lubbock, Texas, United States

November 15, 2017

A. Hi Cody. Tom included an electrical schematic as his first link. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2018

Modifying salt spray chamber for G85 cyclic testing

Q. Hello,

I have to do both ASTM B117 and ASTM G85 A5 tests for my PhD project and, considering the cost for a prohesion testing chamber, it seems more reasonable to acquire a used salt spray chamber and apply some modifications to make it capable of cyclic tests (i.e., G85 A5).

According to G85 A5, fog in the cabinet should be removed in 1 hour sequences. Do you have any recommendations for the pump or fan to suck this highly corrosive fog out of the chamber?

University of British Columbia - Vancouver, Canada

December 1, 2017

Q. Hi, I am an electrical engineering student working with an electrical company. My task is to build a salt fog box. I have a good understanding on how to do this thanks to extended amounts of online reading.

I do though have a few questions that I just couldn't find a proper answer for. I struggle to find information on pumps ... can I use any water pump to pump the salt solution to the atomizing nozzles? What is the simplest way of doing this? Also any information that can be shared on this project will be much appreciated. Thank you.

Andrew

North Power - Whangarei New Zealand

February 1, 2018

A. Hi Andrew,

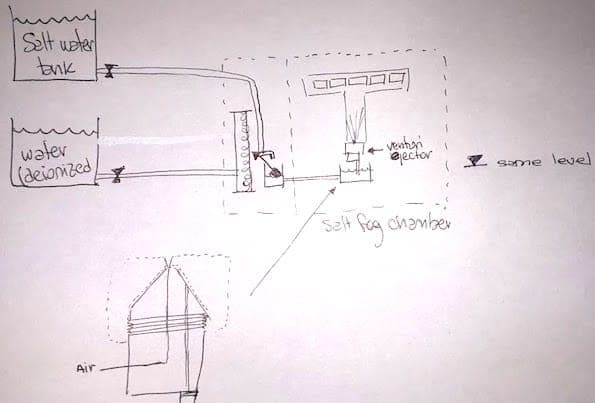

In general, the salt solution goes by gravity to a middle tank (this tank with a floating valve) with the same level as an inner tank, this with the nozzle. This system is feed with water-saturated air, and it sucks (by venturi effect) the water from the inner tank into the nozzle and therefore into the chamber.

There are many schematics of this, but every nozzle I have seen for this type of chambers works the way I described.

Hope it helps!

TEL - N FERRARIS - Cañuelas, Buenos Aires, Argentina

February 5, 2018

Q. Hi Daniel,

thanks for your response. I don't really understand your answer ... can you link me a schematic showing me your method? In a sense all I need to do is create a venturi effect to suck water into the nozzle?

Thanks Andrew

- New Zealand

February 6, 2018

Hi Andrew!

I was sure that what I was trying to explain was very complex to say with words only.

I drew a very schematic view of my chamber, so you can see how it works...

Saturated air is injected into an ejector, which sucks the salt water into the chamber. This ejector has this shape (I tried to draw it as I remember it, as I can't take it from the chamber without interrupting all our assays) that allows liquid to go up because of the low pressure in the upper part, and you can make the volume of this chamber (between the cap and the cone) higher or lower by screwing or unscrewing the cap, this makes bigger or smaller drops in the ejected spray.

Hope this helps you in your project! Best of luck!

TEL - N FERRARIS - Cañuelas, Buenos Aires, Argentina

February 14, 2018

Q. Hi,

First I must say, good job and thanks for sharing.

I have several questions: Do you put pressure cooker on the single burner hot plate? Is the silicone pad heater warming the chamber? Is the chamber isolated well enough?

Thank you for your answers.

Faculty of Mechanical Engineering - Ljubljana, Slovenia

February 13, 2018

February 16, 2018

A. Hi Nejc,

I don't fully understand your questions, because we don't have any burners in our chamber, and I don't know any gas fueled salt spray chamber. So, I will answer the things I understood of your questions:

1- The chamber is warmed by two ways:

a) The saturated air is at 40 °C when it enters the ejector. It cools a little when it comes out the ejector, but heat enters the chamber anyway.

b) There is another chamber full of deionized water under the salt spray chamber. This chamber is heated by an electric heater with a thermostat. It heats up to 60 °C this chamber, and by contact it warms the chamber to a comfortable 35 °C. Keeping some salt water at the bottom of the salt spray chamber keeps it regulated well enough between 34.5-35.5 °C.

2- The chamber is not well isolated, It's only plastic. It doesn't have to be very isolated to allow over-temperature to wear off when it comes to that, and you only need a small heater to keep it working day and night at optimal temperature.

Hope it helps!

Best regards,

TEL - N FERRARIS - Cañuelas, Buenos Aires, Argentina

Q, A, or Comment on THIS thread -or- Start a NEW Thread