-----

How to Increase DFT Paint Thickness in Cathodic Electrodeposition (CED) system?

Low Conductivity Problem - Cause low DFT

This meeting place welcomes Q&As, photos, history, & interesting tidbits.

Please engage with other posters

• When people show interest in each other's situations, the page quickly becomes a fun & informative learning experience for everyone !

• When people show no interest in other people's postings, and just post their own, it often quickly deteriorates into a string of unanswered questions 🙂

Q. Hello everyone and greetings from Turkey,

I work as a technical support staff in a company that manufactures cataphoresis paint in Turkey. One of our customers had a significant drop in DFT. Although we checked everything, we couldn't find a reason and we couldn't find any problem in our Production Line and Paint.

Especially there is a decrease of 3 or 4 microns. So far we have increased the ED tank temperature and voltage slightly, increased the butyl input per shift from 25 kg to 35 kg. This is the only way we have been able to restore the thicknesses but we have not found the main cause. Please point out where we need to check on the line.

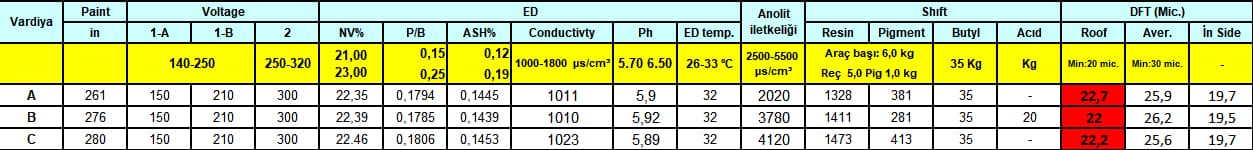

All line details are attached in the photo below.

P.S.: We thought about adding acetic acid but we couldn't afford it because the pH was dropping too much and it was borderline.

Despedida Akinci- Istanbul TURKYE

September 22, 2023

A. Dear Despedida Akinci,

Good day.

Maybe you should pay attention to:

1. increase time of deposition if it's possible.

2. check the efficiency of dialysis cells and its electrodes. Coating surface to electrode ratio should be 4:1/6:1 and current density of electrode according to the specification of the its manufacturer.

BR

- Minsk, Belarus

October 25, 2023

Q. Dear Mr. Belanovich Dmitriy,

Thank you for your reply.

1-We cannot increase the coating time and even aim to reduce it for future plans.

2- Could you please write how I can calculate the coating surface, anode ratio?

First of all, my question may have been slightly changed by the site. As you can see in the photo, our conductivity level is around 1000. Normally it was 1300 µs/cm3. This has dropped over time and we cannot raise it again. We think the problem is due to the conductivity drop. We have serviced and maintained our anodes and found that there is no problem.

- Istanbul, Turkye

October 27, 2023

A. I mean the ratio of the area (external and internal) of the painted parts to the area of the anodes when the bath is fully loaded with parts should be 2:1 to 8:1 with an optimum 4:1.

Another reason for the decrease of conductivity may also be due to the loss of ultrafiltrate or the removal of ultrafiltrate along with painted parts.

Thus, demi-water is added to maintain the level in the bath, and as a result, the solid content and conductivity are reduced.

- Minsk, Belarus

November 10, 2023

⇩ Related postings, oldest first ⇩

for Shops, Specifiers, & Engineers

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. Thickness problem: Is there any relation between thickness of CED coating & and anolyte conductivity?

Avinash VidhateDirector - Nashik, Maharashtra, India

2007

A. There is no relationship between CED film thickness and anolyte conductivity as long as your CED bath conductivity and anolyte conductivity is within the spec.

Anions (CH3COO-) are generated during CED process and it is moving to Anolyte system through semi permeable membrane at the anodes thereby the conductivity of anolyte increases and replenished with DI (maintained with in the spec between 400 - 400 microsiemens). If anolyte system is not removing the Anions then it will be remain in CED bath then the conductivity of bath slowly increases making a difference in film formation.

Please check paint supplier for Bath conductivity and Anolyte conductivity spec.

P.M.Saravanan

paint shop manager

Chennai, Tamilnadu, India

How to increase Electrophoretic DFT (linseed oil base)

Q. How to increase the thickness of electrophoretic paint (linseed oil base) about 35 to 45 microns?

Ammar ahmad- Rawalpindi Pakistan

February 25, 2018

Q. I am Working In CED Paint shop. We are applying 230 V and

pH - 5.82

Conductivity - 1452

NVM - 16.82

But DFT is coming in 5- 10 Micron. Please Tell me How to increase DFT on CED components?

CED Paint Shop - Faridabad Haryana

January 31, 2019

Q. Dear sir;

I am working CED line for past 8 years. I faced a lot of problems and I found solutions for them all, but now we are facing a new problem for past 2 years, and it's increasing gradually:

Low DFT --

Components are coated with less DFT (lower side) remaining sides are uncoated with zero dft (upper side) of same components.

Please someone give a solution for this problem.

Thanks all.

- CHENNAI TAMILNADU

March 27, 2021

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. What will be the DFT variation in aluminium as compared to sheet metal component when DFT related bath parameters are constant?

Mustafa khanQ. Head - Faridabad, Haryana

February 14, 2023

Q. I am Working In CED Paint shop. We are applying 250V at step 1 and 300V at step 2. But still coating thickness is <10µm (STD 18 ~ 22 µm)

*E-Coat Bath Parameters*

pH - 4.8

Conductivity - 1172µS/cm

NVM - 19.82%

Ash - 21.7%

anolyte conductivity - 1200 µS/cm.

Part - Galvanized

MEQ - 32.44

Bath Size = 68 cu. m.

permeate Flow = 20 L/min

*Coating Parameters*

Coating/Bath Temperature = 32 °C

Coating Time = 4 min

Soft Strat/Ramp-up Time = 30 sec

Step 1 Voltage = 280 V

Step 2 Voltage = 300 V

Area to be Coated - 118 sq.m

inside Area DFT < 6 µm

Outside area DFT < 10µm

Please help me How to increase DFT on E-Coat/CED components?

- Lahore, Pakistan

February 18, 2023

A. Hi Arslan.

I do not have any experience in this to be able to help you, but I note that dozens of readers have the opposite problem -- thickness greater than they want -- and Topic 23047 "How to reduce CED paint thickness?" will tell you what they had to do to decrease thickness. This may well tell you what you are doing which is limiting your thickness :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread