-----

Gold plating specifications - why is plating bright vs. matte?

2007

Q. We have a part for which we specify gold plating for an electrical contact simply as "hard gold, 10 microinches". The substrate material is phosphor bronze, 1/4 hard.

The latest batch arrived from a new vendor with a matte finish instead of the bright finish that we have been used to. The plating thickness measured correctly at 10 microinches.

Questions:

1) Does a matte finish indicate that there may be something wrong or with the plating process that was used?

2) Is it usually necessary to specify "bright" or "matte" finish?

3) Can someone suggest a more thorough plating specification that would cover all necessary information?

Thanks!

engineer - Guilford, Connecticut

A. Dear Matt,

I shall try to answer to your questions as follows:

Questions:

1) Does a matte finish indicate that there may be something wrong or with the plating process that was used?

GOLD PLATING ON ITS OWN DOES NOT GIVE A BRIGHT FINISH. THE BRIGHTNESS DEPENDS UPON THE BASIC BRIGHTNESS OF THE BASE METAL. FOR THIS USUALLY A BRIGHT NICKEL/SULPHAMATE NICKEL UNDERCOAT IS GIVEN PRIOR TO GOLD PLATING. CHECK WITH your VENDOR.THERE ARE MATTE GOLD FINISHES AVAILABLE. BUT IT IS GENERALLY USED FOR DECORATIVE OR VERY SPECIFIC REQUIREMENTS.

2 Is it usually necessary to specify "bright" or "matte" finish?

YES. BUT your REQUIREMENT IS ELECTRICAL CONTACTS. THERE IS NO NEED FOR MATTE FINISH. NEVERTHELESS NO MATTER.

3) Can someone suggest a more thorough plating specification that would cover all necessary information?

MATT: You SHOULD BE CONCERNED ABOUT THE HARDNESS WHICH HAS TO BE IN RANGE 160-200HV. IF IT CONFORMS TO THIS SPEC, I DO NOT SEE ANY PROBLEM. YOUR POSTING DID NOT MENTION THIS BUT ONLY SAID "HARD GOLD"! YOU MAY PASS THIS AFTER CHECKING THE HARDNESS.

REGARDS,

T.K. Mohan

plating process supplier - Mumbai, India

Electrochemical Metallizing by Marv Rubinstein

on eBay or Amazon

or AbeBooks

(affil link)

Q. I am in need of plating some idols in gold. Is it cheaper to do it myself using brush plating method (the largest is 18 inches high) or should I give it to a professional plater?

RFQ: If I am doing brush plating, where can I get the kit in India and detailed instructions? Suppliers can mail me.

Sankara Menon- Cochin, India

July 18, 2011

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi, Sankara.

It is usually faster, easier, and less expensive to do tank plating unless there is a specific reason to do brush plating. In the case of gold plating, where labor is a much smaller part of the total cost because of the high cost of gold, sending it to a plating shop may save money rather than cost money.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

July 19, 2011

How is this watch dial finished?

Q. Hi all,

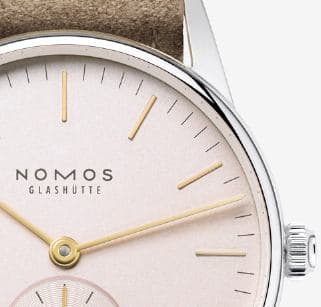

I'm wondering what is involved in finishing brass (I presume it's brass as this is the standard dial material) to make it look like this Nomos watch:

The manufacturer's website mentions plating with gold and silver, and 'galvanising' but it's a much softer, more matte finish than plating I've seen before.

Does anyone know how it's done?

designer - London, UK

June 22, 2015

by Reid & Goldie

-- hard to find & expensive; if you see a copy cheap, act fast!

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Lewis. We appended your inquiry to an earlier thread about matte gold plating which should offer you food for thought. There probably is no bright nickel plating below the gold -- perhaps dull nickel. There might also be an ultrafine glass bead blasting. Obviously we can only talk in generalities about how such things are usually done, not how Nomos actually does it, as we must be careful to avoid crowd-sourcing industrial espionage :-)

Another thing is that various colors of gold are available for watch plating (achieved via different percentages of alloying metals).

Usually faster progress will be made towards getting helpful answers if you explain your own situation. For example, dull nickel plating or alloys with a lot of non-gold may be no problem for watch dials sealed behind crystal, whereas adopting these answers to other product lines might be highly problematical in terms of nickel leaching, tarnishing of low alloy gold, etc. There is little concern about corrosion or leaching when components are sealed in a waterproof case, but the plating on those watch hands might not fare well if exposed to the world :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Gold plating from tetrachloroaurate [AuCl4]

Q. My question is regarding brightening additives for decorative plating.

1. The article below shows some additive mixtures, but only for Potassium Gold Cyanide. Would it be possible to use the same mixtures for Tetrachloroaurate (Gold dissolved using Aqua Regia?)

2. Is a nickel underplating enough to obtain jewelry brightness, or do you need have the additive mixture?

http://paperity.org/p/3954099/bright-gold-electroplating-solutions

Gold Plating - San Jose, California, USA

October 8, 2018

by Reid & Goldie

-- hard to find & expensive; if you see a copy cheap, act fast!

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Kevin. Reid & Goldie says that KAuCl4 was considered as far back as 1845 by Elsner, but it does not otherwise address it in the whole 630-page treatise. I find no other obvious reference to gold plating from AuCl4 in my plating library and I've personally never heard of it :-(

Best of luck to you, but I think the chances of successful plating from such a solution are nil regardless of what additives you employ. Please explain what motivates you to try such a composition. Thanks.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thank you ted. I figure it would be nice to have a non-cyanide solution because of the prolonged exposure side effects; it's a big industry and regulations are getting more strict against working with these chemical.

Thank you ted. I figure it would be nice to have a non-cyanide solution because of the prolonged exposure side effects; it's a big industry and regulations are getting more strict against working with these chemical.

Gold Plating - San Jose, California, USA

October 11, 2018

A. Hi Kevin. Not to discourage further research in any direction you wish to take it, my understanding is that gold sulfite baths are the only production-viable alternative to cyanide.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 2018

October 15, 2018

A. Hi Kevin

I have seen gold chloride baths used in commercial refining. The deposit is very pure but the quality of the plating is rubbish.

I know of no long term effects of cyanide. At sub lethal levels, the body has several mechanisms for eliminating cyanide which is good because cyanide is present at low levels in the environment and even some foodstuffs.

In any case, plating baths based on gold potassium cyanide contain very little free cyanide.

I agree that the safety community tend to be paranoid about anything associated with the C word but this is largely based on ignorance.

We understand cyanides very well but the same cannot be said for any of the proposed alternatives.

You can find considerable factual detail at

https://www.academia.edu/10635761/Cyanides_in_Metal_Finishing_Risks_and_Alternatives

Geoff Smith

Hampshire, England

Q. Hello there. Nice to meet you all of you. You can call me Phu. I am final year undergraduate student who is doing project with this gold plating on copper and brass using non cyanide bath for decorative applications.

My question is what is the use of brighteners in the gold plating solution? Does this not make the gold plate bright enough? Do I still need to plate bright Nickel layer first in order to have a bright finish of gold?

Yangon Technological University - Yangon, Myanmar

June 4, 2019

|

A. A good bright gold solution will plate bright on your bright brass substrate without using nickel but if your gold solution does not contain brightener it will plate dull on your bright substrate Neil BellAlbuquerque, New Mexico June 4, 2019 A. Hello Phu, Electronic Plating - Winston Salem, North Carolina USA June 5, 2019 |

![]() Thank you guys.

Thank you guys.

- Yangon, Myanmar

June 6, 2019

Q, A, or Comment on THIS thread -or- Start a NEW Thread