-----

Black spots problem in anodized aluminum

Q. Hi Jack Zhang.

We have the same defect on the same alloy 5083.

How did you solve the problem?

Anodizing plant Owner - Italy

August 8, 2023

A. We resolved this problem by reducing the etching time.

Jack Zhang- Suzhou China

August 8, 2023

Aluminum How-To

"Chromating - Anodizing - Hardcoating"

by Robert Probert

Also available in Spanish

You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

![]() Hi Jack Zang,

Hi Jack Zang,

Thanks for the reply.

I'm glad to know you solved the problem.

Q. I also tried to reduce the etching times and even skip the step. The problem continues to occur. I believe it is related to the alloy. In this regard, I ask you if you have changed supplier of 5083.

The operating data of my anodizing tank are as follows:

Sulfuric acid: 150 g/l

Aluminium: 7 g/l

Additive glicolic/oxalic based: 30 g/l

Temp: 1 °C (33,8 °F)

Strong air agitation

Anode recipe:

1) ramp: 3 min at 1,8 A/dm2 (18 ASF)

2) stasis: 20 min at 1,8 A/dm2

3) ramp: 5 min at 2,4 A/dm2 (24 ASF)

4) stasis: 45 min at 2,4 A/dm2

Coating thickness: 40 microns

Do you think I should raise the concentration of sulfuric acid to 180 g/l?

Thanks

- Italy

August 9, 2023

⇩ Related postings, oldest first ⇩

Q. Gents,

I'm working in an anodizing plant and we have one defect that I hope you can help me to solve it.

Sometimes we notice some black spots in the aluminum profiles. Those spots will not be shown before anodizing; you can see it only after anodizing process. The hardness is very low in these spots.

When we analyze the sample we got the same chemical composition in the good and defected area. We are producing 6063 with below analysis. Can you please clarify this defect to me and how can we avoid it?

Thanking you for your best cooperation.

Production Engineer - Dammam, Saudi Arabia

2007

A. Hi Sultan,

It's an extruder's problem - this is known as HOT SPOTS defect, mostly in elliptical shape and in various sizes. You cannot do anything to it in your surface treatment facility. Extruders have to improve the cooling of hot extrusions during extrusion process. You can send an official complaint to the extruder for the replacement of those profiles.

Good luck

- Dubai, U.A.E.

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

on eBay or Amazon

or AbeBooks

(affil link)

Q. Does anyone know if these spots can also occur in aluminum forgings (in particular 7049) as they do in extrusions?

Rocco Varano- Longueuil, Quebec, Canada

May 26, 2008

Q. I have the same problem with 7050-T6 sheet, do you think the reason is also these "hot spots"

Thank you.

- Seattle, Washington

February 20, 2009

Q. I am experiencing black spots on parts machined out of AL-7075 after the parts are clear coat anodized at 20 micron. What is causing the black spots and how can they be eliminated and overcome this problem?

Arthur Kooemployee - Hong Kong, China

April 10, 2009

A. Yes. I have encountered the same Black spot after anodizing.

There were no black spots before anodizing.

This may be due to heat accumulation during machining. I feel we need to use good quality cutting Fluid during Machining to avoid the same.

- Bangalore, Karnataka, India

July 14, 2010

Q. Hello,

I am having issues with an aluminum profile extruded out of 6005 that we use on semi trailers. When we get the product it is perfectly fine, then we apply a swirl pattern to it with our brush machine. Next we seal the piece with an Alumaclear coating then clean the trailer. Once the trailers leave we have an issue with black/lines appearing at the seam lines. They occur anywhere from 12 hours to 1 year after the trailer leaves. We have tried to reproduce the effect at the factory and it never occurs. We were getting the phenomena before we started sealing hoping that Alumaclear would be our answer. Can anyone tell me what would cause this to happen after a period of time?

Thank you for your time.

Purchasing - Knox, Indiana, USA

January 23, 2013

by Runge & Kaufman

on eBay or Amazon

or AbeBooks

(affil link)

Q. Do you think if the same "hot spot" problem happened to this part, too? We outsourced these parts and hundreds of black spots appeared on the surface.

We use Al 6061 alloy to machine parts, but these parts were outsourced to China. They were supposed to use the same alloy. However, I realized that the parts before anodizing were more bright than our parts.

I was wrong in my previous message.

The parts were etched (NaOH) for 3 minutes, and then de-smutted (HNO3) for about an hour (I don't know why so long) when they developed these spots, which are actually small "craters". So they haven't even reached the electrolyte bath for anodizing.

I'm attaching here a better picture.

I've just tried with another batch of parts (also Chinese, brighter parts) and there was no problem."

- Salatiga, Indonesia

August 28, 2013

A. Has enough nitric acid dragged over from the deox into the anodizing tank, or do you have high chloride contamination in the anodizing tank? You can make holes like this in 6061 if the anodizing solution is contaminated with nitric or chloride.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. We are experiencing black spots on polished sheet metal (Aluminum 2219, T62) formed parts after anodize, which is outsourced. Before anodize parts are visually inspected for pits, black spots.

Can anyone tell us what the cause is and how to prevent it? Thanks in advance.

Aerospace - Los Angeles, California

April 17, 2014

A. Parts look DA sanded for your finish. It's hard to say for sure, but the first place I'd start would be your sandpaper. It's possible you are embedding media from the sandpaper into your aluminum. Make sure you use sandpaper that has AL2O3 as the media, do not use Silicon Carbide sandpaper for anything that gets anodized.

Marc Green

anodizer - Boise, Idaho

![]() Thanks Marc. We use only aluminum oxide media.

Thanks Marc. We use only aluminum oxide media.

Aerospace - Los Angeles, California

A. S. Gunnam,

I'm not clear as to whether you're the end user of the product, the anodizer, or whether you're the manufacturer and you just outsource the anodizing. It would help to know what parts of the total process on this part that you have direct control over, so we'd know what your limitations are in solving the issue.

It sounds like we've ruled out the obvious, and easiest to fix potential problem with the sandpaper. I downloaded the pictures and blew them up a bit to try and get a close up. Of course, I lost a bit of resolution. It really appears to be some type of contamination, now, whether it's coming from the base metal, something in the machining process, or yes, perhaps something still could be in the finishing process, and finally, something going on in your anodizing process.

Are those black marks raised, or are they pitted? Are you getting continuity on the black marks? When I enlarged the pictures, they look like pits, but hard to say for sure.

Does the issue still appear if the parts are reworked?

It really looks like you're seeing a base material issue. Now the question would be, is the contamination in the material itself, or is it being embedded during subsequent machining or surface finishing operations.

I'm a bit spoiled as an anodizer, as my shop has SEM/EDX capabilities to analyze stuff like this. And that's how I'd start, would be to sacrifice a part, and run an EDX analysis on the black area, to identify what I suspect is some type of metallic contamination. Once it's identified, look at the process from start to finish to narrow down the source of the contamination, beginning with the material itself.

Solving issues like this by looking at pictures with extremely limited process information on the internet is practically impossible. I could list at least dozen or two potential causes. So all I can do is tell you where I'd start, and that would be with the EDX analysis.

Identify the contamination, and then find the source.

Marc Green

anodizer - Boise, Idaho

A. Check the base aluminum of crosscut.

Jimmy Kim- South Korea

June 1, 2021

Q. Hi Guys,

We experiencing the similar black spot after anodizing. In our case the Aluminium parts 6061 been tumbled then sand blast at our customer side.

Then we'll do Chemical Polishing then anodizing. The black is more visible only after anodizing. Need some inputs very urgently.

Regards,

- Penang, Malysia

by V. F. Henley

on eBay or Amazon

or AbeBooks

(affil link)

Q. How to avoid black spots on 2XXX & 7XXX series aluminium alloys after anodising? We are getting repeated issue.

We controlled the machining speed (reduced the speed, feed & depth of cut) and reduced anodising voltage ramp-up rate and protect them with rust preventive oil. But even after. we are not able to arrest the aluminium getting black spots after anodising.

Metallurgist - Bangalore, Karnataka, India

April 3, 2015

A. Typically, with 7000 and 2000 series you'll notice an extremely quick dye time. I've found that most of what I run of that alloy dyes in five to 7 minutes. I too have experienced the pits and it's fairly simple to avoid. Basically your parts are getting attacked from to much time in dye. I suggest when dying the parts monitor them (stand by the tank and look at them); when they are black, remove from dye, rinse well and seal also. If you leave for long duration in seal with this alloy you may also see white spots; all can be avoided with better attention to parts and tank chemistry. Good luck.

Jake zeesmetal finishing - marysville Washington

June 24, 2015

A. Gentlemen, this black spotting in this thread is traditionally due to the oxidizing of the aluminum which can occur through acid contamination in the pretreatment process. Several have noted that they have seen this prior to anodizing or prior to coating, and that would support creation of the defect in the pretreatment process.

Regards,

- Morton, Illinois USA

January 9, 2017

Q. Hello,

We are an aluminum door handle producer.

We use ALMG3 alloy with 3% Magnesium content.

We casting the door handles by gravity die casting with a small ladle.

We are facing a problem of black dots that are showing only after the anodizing process.

Please help us to find a solution.

Thank you,

STE ALUCAST SARL - Fouchana, Tunisia

March 8, 2018

A. Hello Mr. Daaboul,

I am assuming that you have made it through all the great information in this thread and eliminated things like chlorides in your anodizing tanks as suspects...

Although I cannot answer your question, one simple thing you can do to give the community more clues and maybe help you, is to take a couple of your finished castings and cut them down the middle and then anodize the halves and see if the spotting appears in the centers of the castings as well. What this will at least tell you is whether your problem is arising only at the interface between the die and the part, or whether it is throughout the material. Tell us what material your die is as well, and also if any other materials might be introduced into the mold, intentionally or as contamination, and how you are cooling the casting, over how long a period of time, and how/if you are cleaning it off after it is unmolded.

Another piece of information would be whether you are then polishing down the castings, and with what type of abrasive, and how thick a layer are you taking off.

I must declare that I have ZERO real-world experience with the casting process; these questions are only from a basic theoretical understanding from an anodizer's perspective of where one might begin troubleshooting- I have certainly seen parts milled from castings behave badly when plated (poorly-done extrusions, too!), someone with more specific experience relating to your issue will no doubt see your question eventually :)

The more information you give, the more you will get in return! Good luck!

Rachel Mackintosh

Lab Rat / WWTF - Greenfield MA

April 10, 2018

Black spots in anodized aluminium EN AW 5754

Q. Hi all,

we are a middle-sized plant focusing on CNC machining. Part of our production are aluminium parts. Some of these parts are anodized (outsourced). For quite a long time we've been having a problem with small black spots on the surface. It happens to occur on EN AW 5754 material. Spots are mostly longer, in different layers of the material. We know it's not caused by the supplier of the anodizing, since we tried more suppliers with same result.

We also weren't able to find any correlation between content of any element in the material and the spots.

Sometimes re-anodising helps, sometimes not, and the spots appear on different areas.

Does anyone know what is the cause of these spots/how to get rid of them?

Thanks for any advice.

Quality manager - Nosislav, Czech Republic

October 17, 2018

A. Hi Libor, you say you've tried a different anodizing supplier ... but have you tried a different supplier for your aluminum stock?

Based on the information you gave, that the defect is in different layers, can sometimes be stripped and reworked but might pop up in another spot, and you are running a high Magnesium wrought alloy (Mg goes black like that) ... If those defect lines are always oriented the same, corresponding to the direction of extrusion, I would wager my paycheck on a material issue!

Rachel Mackintosh

Lab Rat / WWTF - Greenfield MA

Q. Hi Rachel, Changing of the supplier of the material was one of the first things we've tried. And not only the supplier, but more importantly, the manufacturer of the material. And it's still the same problem with all of them.

However, I definitely agree it's a material issue. Question is, what is wrong? What particular quality of the material is causing these black spots? I've been looking into composition of each batch and trying to find some feature which would be common for the batches where spots appeared. So far without success. You mentioned Mg. This particular material can contain 2,6 to 3,6% of Mg according to standard. But there is no significant difference in Mg between OK and NOK material batches.

Thanks for engaging!

Libor Böhm [returning]Quality manager - Nosislav, Czech Republic

October 18, 2018

|

|

A. Hello Libor, - Hallau, SH, Switzerland A. Hi Libor, - sakarya,TURKEY |

Q. Hello,

thank you Joerg and Alaattin for your posts. Basically, we all agree that it is a material issue. But it's not sufficient reason for raising an official complaint towards material producer. As you say, Joerg, specification is very important. I'm trying to find some specific material quality to look for (max. % of specific element for instance).

Here are some other pics of the defect.

Simplified sequence of the anodizing process we are using is here:

1. Alkaline degreasing

2. Pickling E0

3. Pickling E6

4. Alkaline rinse

5. Clarification (HNO3/H2SO4)

6. Alkaline rinse

7. Anodizing (H2SO4)

8. Acid rinse

9. Coloring

10. Rinse

11. Sealing

12. Rinse

13. Drying

Thanks for your opinions!

Quality manager - Nosislav, Czech Republic

A. Hi Libor,

I think the source of the problem is the alloy or casting process as per previous contributor's opinion. If you suspect it comes from the process then you can try 2 options:

1- you can skip only clarification bath's rinse (alkaline rinse as you describe)

(we call it "neutralization" bath instead of "clarification" bath). Also you had said "alkaline rinse" but I think it should be "acid rinse"

2- you can skip only E6 etching bath and its rinse

So, if you see again the black spots, then focus on material problem ... don't think anything else.

- sakarya,TURKEY

A. Regarding the 5754,

if you're using your own forming process on the product, look for sources of debris, like steel shavings, etc., that might get embedded into the soft surface. I've anodized quite a bit of 5745, have seen other issues, but nothing like this -- this reminded me of some 6xxx series parts that sat in RO water (high purity) overnight, they were cleaned, etched, deoxed and ready to be anodized, but it was very late in the day and had to be rescheduled for next morning, and those parts developed defects similar to these, very few spots, not regular at all, but deep craters (visible on high magnification) that were very very noticeable after anodizing.

- Riga, Latvia

October 25, 2018

Black streaking in anodized machined aluminum part

Q. Hi all,

I've got this part machined from 7050-T7451 aluminum, and after anodizing per MIL-A-8625 / MIL-PRF-8625

[⇦ this spec on DLA] (Type II) its coming back with black streaks.

Now these parts are not aesthetic, so I'm not concerned by the appearance of the black streaks, but I am concerned about whether or not they pose a concern for corrosion resistance and material properties. So my question is, do imperfections in anodizing have a significant effect on corrosion resistance or material properties?

Thanks!

- Vacaville, California

October 18, 2018

A This is what happens when the material has been COLD DRAWN

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

A. Regarding 7xxx,

there are quite a few posts about this very problem on here, and nothing very definitive. From my own experience, I see those gray lines when the part has been either reworked, the stock material has been sitting for a long time before a part was machined from it (years), or misalignment of Mars and Venus during anodizing. It should affect corrosion resistance -- how much, no one will give a definitive answer; put it in a salt spray cabinet to see how it behaves. But then again -- if corrosion resistance is so important, why 7xxx series? Is weight/size that much of an issue where you can't use a purer alloy that will anodize better and provide better corrosion resistance?

Here is a photo of a part made from 7075 I anodized:

There is a large bore in the part from left-right (during machining it may have been warmed up, though flood coolant was used), and the pattern seems to be somewhat oriented around it, suggesting a relation to internal stresses in the part, which supports what Mr. Probert said about cold drawing.

Janis Ziemelis- Riga, Latvia

October 25, 2018

Q. I have seen the exact same black spots & streaks on the parts we anodize. The streaks occur along the machining tool path, and the small black spots often deep occur on the surface of the machined part. My analysis has pointed me to the material, for example the actual process of rolling or manufacturing the Al5754 metal plates. Also the problem is random for the black spots.

Is there a way to clean/etch the part with a certain kind of chemical to avoid this problem?

Can anyone share some more light on this?

Aerospace - Chiang mai, Thailand

November 20, 2018

Q. Hello all.

We are involved in aluminium foundry, working with AC2A alloy castings. We are also facing the same black spot problem. these black spots are observed only after anodizing process. We are not able to find out its real reason. Please suggest some feasible solutions.

- Jalgaon, Maharashtra, India

February 8, 2019

Odd black stain on anodized aluminum - what is it?

Q. Preface : I am just a simple consumer - I have no idea about terminology, etc so I apologize ahead of time if things are confusing or not well explained.

I bought a custom keyboard awhile ago. When it arrived I noticed that there is this slight black stain in two spots on the aluminum case(which I'm assuming is anodized).

Regrettably I let my apathy of having to ship it back to China get the better of me; decided I can live with it and maybe get it re-finished later since there are other imperfections I wouldn't mind fixing if possible(open to suggestions of shops in the Bay Area!) but in short -

I am curious as to what this stain is and what can cause things like this to happen. I'm hoping someone on the forum has an answer or at least a clue as to what this might be.

To start off, the manufacturer says the casing is made from 6063 CNC'd aluminum; that's unfortunately about all I know

The stain appears basically as a slight black line. I don't believe it's just crud on the surface as

1. I am unable to rub / pick it off

2. The visibility of the marks can change depending on the lighting and angle of viewing

3. The color can also change depending on the lighting and angle; depending on how you look at it, the mark can turn white or blend in completely with the rest of the finish.

I also discovered today that there might possibly be a slight chip near one of the stains in whatever is coating the top after running over the stain with a plastic pick while contemplating whether or not to try isopropyl alcohol to see if the stain would come off. Maybe some kind of contaminant got in somehow?

Anyways, that's about the best I can describe things. Happy to try and clarify if need be.

Thank you!

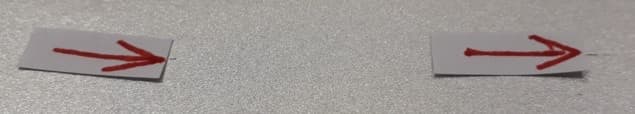

You can see some photos of what I'm talking about here:

(stain circled in red)

(another shot, with flash to hopefully give a better sense of how the case is currently finished)

- Santa Clara, California, USA

March 5, 2019

A. Hi Joe. I don't want to trivialize something that you perceive as a problem, but my personal opinion is forget it! It will cost you a couple of hundred dollars to get a shop to even try to improve on this and there's no guarantee that they will be even as successful, let alone more so.

In a way it's a bit of a shame that Apple was so successful with their aluminum iPhones because it's raised the expectations of consumers to unrealistic levels. A perfect cosmetic finish on a keyboard housing is fairly difficult, although it is easier on 6063 than on the 7XXX alloy of an iPhone 6S, and reworking a problem like this doesn't sound promising. If a shop tells you they can fix this, more power to them, but I don't think it's going to happen :-(

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. In my opinion, based on the picture: It is a fine oxide line in the aluminum base material.

But it's just a decorative problem.

The very fine oxide line gives an anomaly distortion with discoloration of the layer. A removal is not possible.

But the little irregularity does not change, no problem.

This is not an extraordinary irregularity. Can always occur in individual cases, even with very good material and anodizing quality. I know this, for example also with covers (labels, covers for machines, coffee machines, etc.).

In production as much as possible a good metal quality is used. Single errors are sorted out. But nothing is 100%, this small irregularity was overlooked. Customers are very sensitive today. Often parts are destroyed that are still good. Think, you have a unique piece!

- Hallau, SH, Switzerland

![]() Just wanted to quickly write back and say thank you for the responses!

Just wanted to quickly write back and say thank you for the responses!

Yea - I agree with your assessment. I'm actually not terribly concerned about the issue, it's more annoying than anything; I was really more curious as to what causes these kinds of issues for my own edification.

Thank you too for setting expectations as to whether or not to re-finish; figured it wasn't gonna be cheap based on what other folks have said too. Despite that I was still considering it since there's other minor bits of damage on the inside as well and plus, I figured since it's probably not gonna be cheap anyways, might as well see about getting the case re-painted / re-coated while I'm at it; I did not expect the color to be as light as it was when I ordered and would not mind it if the color of the case were a bit darker.

Anyways, thanks again for taking the time to answer and thanks for running the site. Have a great rest of the day!

- Joe

- Santa Clara, California, USA

Q. Spots after hard coating?

We had 6061-T6 parts that had to be hard coat anodized. We sent 2-3 test specimens to anodizers to see thickness of 50 µm on specimens.

They did pretty good job on test ones, but when we sent whole batch, it was ruined by some weird spots on them.

Can someone tell me what went wrong and where?

Thanks.

Onio Tan- Croatia, Zagreb

March 10, 2021

|

|

A. This "galvanized-looking-appearance" can sometimes be caused by the alkaline etch when the sodium aluminate has gotten to high. The short time fix is to add a smidgen of hex chromium to the etch (Alcoa in 1957). The real fix is to bleed & feed to lower the sodium aluminate.  Robert H Probert Robert H Probert Technical Services Garner, North Carolina  A. According to the pictures, there is a coarser grain structure. Therefore the spots depend on the microstructure. It is possible that the test batch was not from the same batch or there are structural differences in the batch. This is quite possible with press material. Joerg Beerli- Hallau, Switzerland |

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. Now we also meet a same problem as yours.

How do you deal with problem?

- Suzhou China

May 10, 2021

A. Hello Jack. Please offer details of your own problem. No one answered Onio as of the time of your posting, perhaps because there wasn't enough info provided? He said his parts were ruined, but I didn't see clear evidence in the pictures that they were ruined. Why do you consider your hard anodized 6061-T6 parts ruined? Please post pictures and explanation of why you consider them ruined. More than a dozen quite similar questions have already been asked and answered on this thread, but "the devil is in the details". Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Onio and Jack

The lack of uniformity showing is likely the grain structure of the aluminum. Anodizing brings it out, but it wouldn't surprise me if the parts were heavily etched before anodize, or stripped and re-anodized. Sheet metal typically does not significantly show the grain after anodizing. Reduce the etch time to a bare minimum (just enough to ensure a clean surface).

If etched excessively, the grain will show before anodizing.

- Green Mountain Falls, Colorado

May 12, 2021

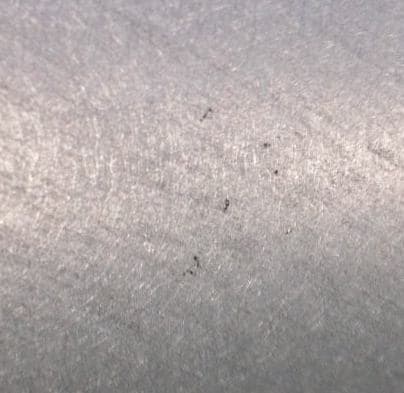

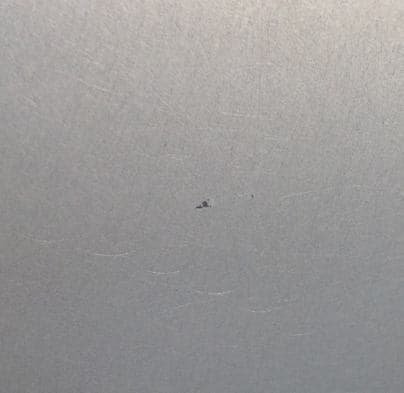

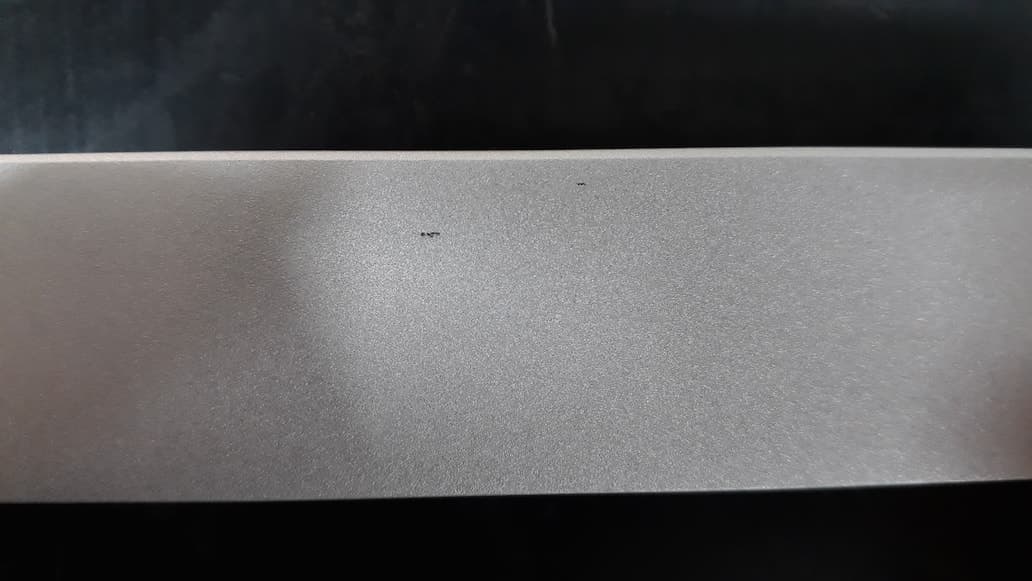

Q. The material is 5083, Total 11 parts in one bath, but after anodizing only 2 pcs are ok. 9 pcs were ruined.

(We sanded 2 ruined parts and chose 1 of them to do the anodizing again. Also so many grey spots appear.)

(After sanding and before clear anodizing)

(After anodizing.)

- Suzhou China

Q. When I anodize 5052 aluminium, I always find black line or black dots on customer part which I could not see before anodizing. And this problem appears only on 5052 material but not all 5052 aluminium parts.

I tried anodizing customers' part and the 5052 aluminium coupon that I have with exactly same parameter, customer's part showed black dot/black line but the coupon did not show any black dot/black line. Why does this happen and how should I avoid the black dot/black line?

The black dot/black line visible only after anodizing ==>

The process:

1) Degreasing

2) Demineralized Water Rinsing

3) Alkaline Etching (Tried skipping alkaline etching but it doesn't help)

4) Demineralized Water Rinsing

5) Desmutting

6) Demineralized Water Rinsing

7) Anodizing (H2SO4 180 g/L, Aluminium 7.72 g/L, 15A/sf, 7 microns)

8) Demineralized Water Rinsing

9) Nitric Acid Dipping

10) Demineralized Water Rinsing

11) Nickel Acetate Sealing

12) Demineralized Water Rinsing

13) Hot Demineralized Water Rinsing

14) Oven Drying

Thank you for your help.

Muhammad Afiq- Johor Bahru, Malaysia

July 2, 2021

Readers -- please see thread 48164, "Pitting and black spots during Anodizing" for more photos and discussion of possibilities.

Q, A, or Comment on THIS thread -or- Start a NEW Thread