-----

How to do Electroforming to make gold jewelry

for Artisans, Jewelry, Crafts

avail from eBay, AbeBooks or Amazon

avail from Amazon

avail from Amazon

avail from eBay, AbeBooks or Amazon

avail from eBay, AbeBooks or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. Hello experts,

Considering your deep knowledge and enormous experience, I was wondering if you could introduce to me some paper, book or any reference in the context of 18K gold alloy electroforming. I've spent plenty of time searching on the internet about available papers about this scope. But I've got still many questions about the solution parameters that need to be checked (and the method of measurement) during electroforming of 18K gold alloy. The main bath that I've come up with is based on Au-Cu-Cd and I succeeded to gather electroforming parameters in terms of current density, pH, time, temperature, and the required additives. However, the parameters which ought to be controlled during electroforming for a uniform deposit with the same karat (18K) throughout the thickness are still under question for me. It would be nice of you if you help me to find the answers to my questions and introduce me to some references.

Regards

- Tehran/Iran

July 27, 2023

Q. Hello, I am Amin Darvishi from a company active in the field of jewelry production

We want to buy an electroforming machine, but we don't know which company is the best? [list of 3 vendors deleted by editor]

So can you help us?

R&D - isfahan

August 15, 2023

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

⇩ Related postings, oldest first ⇩

Q. I am looking for information about gold electroforming for coping with my senior project. I am so interested in this approach, please help me.

I hope to receive good news from you. Thank you.

student - Thailand

2000

A. Hello, Soiwisa.

Electroforming is essentially the same thing as electroplating. It is called electroforming rather than electroplating when an object is actually made by the electroplating process. For example, hollow gold jewelry may be made by electroplating gold onto a core of wax and then dissolving away the wax, leaving just the hollow gold object. Because the electroplated layer comprises essentially the whole object that has been formed, rather than just a plating on the object, it is called electroforming.

Eelectroforming may not always be exactly the same as electroplating because certain practical problems begin to arise as the coatings get very thick which may require adjustments in chemistry, operational parameters, and methodology. But as far as a senior project, researching & studying gold plating should do it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I am 17 years old and have been cutting Australian Opal for the past 4 years. Currently I can put opals into jewelry that has been pre-fabricated however I have been unable to set freeform stones. I have been really interested in the electroforming process and I have been desperately searching for more information regarding the process.

David DawsonDownunder Gems - Perth, Australia

2003

Q. I would like to know in detail regarding the principle, process, technique, machinery required (with detailed specifications and budgetary requirements) of GOLD ELECTRO FORMING for Jewelry. Kindly provide me the details.

Thanking you,

Indian Institute of Technology - Guwahati - Guwahati, Assam, India

2003

A. Hello David, Hi P.S.,

Again, electroforming is essentially the same technology as electroplating -- it's mostly a matter of semantics: If the item which is electrodeposited upon is the heart of the matter, as for example a circuit board or truck bumper, it's called electroplating; if the electrodeposited layer becomes the item, as for example a hollow gold earring or a stamper for vinyl records, it's called an electroform; if it's arguable which is the heart of the matter, for example a copper plated maple leaf, it might be called either.

Obviously there are countless electroplating textbooks, but in addition a search of the plating literature with scholar.google.com will reveal dozens of technical articles on electroforming, and there are a few books on electroforming. Your local plating process distributor will be able to help with sourcing of chemicals & equipment.

Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2003

Q. Dear sir,

I would like to know in detail regarding the principle, process, technique, machinery required (with detailed specifications and budgetary requirements) of GOLD ELECTROFORMING for Jewelry.

Kindly provide me the details.

Thanking you,

- Mumbai, Maharastra, India

2006

Ed. note: Your teachers must have loved having you in their classes, Peter :-)

Multiple threads merged: please forgive chronology errors and repetition 🙂

Electroforming of gold jewelry

Q. WE WANT TO DO ELECTROPLATING ON NONCONDUCTIVE SUBSTANCE. IT IS REGARDING WAX PLATING. KINDLY GUIDE ABOUT CHEMICALS REQUIRED , NAMES & AVAILABLE FROM . THANKING YOU.

NIREN MADHUBHAI SONI.GOLD JEWELRY - RAJKOT, GUJARAT, INDIA

2004

A. Hi, Niren. For a general introduction, please see our FAQ on plating of non-conductors. If you search the site you will see about a dozen threads on various aspects of electroforming.

But electroforming of hollow gold jewelry, electroforming of record stampers & CD molds, etc., are well developed technologies, and if you go to your local supplier of electroplating process chemistry they should be able to introduce you to the equipment and chemicals needed. Good luck!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Jewelry artist wants to electroform on opals

Q. Greetings,

I have been cutting opal for years and was thinking about trying to electroform some of my freeform shapes. Can you give me information on a good system to buy and how do you attach a bail if you wanted to make a pendant. Any help on this would be great.

Thanks,

Opal Cutter - Copperas Cove, Texas, United States

2004

Electroform gold jewelry products around the stones in place

Q. I am a product developer in the field of fine jewelry. We have been using 14K cold bath process in which semiprecious stones are set in wax mandrels, masked and then electroformed to set stones in place. Do you know whether a USA patent for stone setting in electroform skin is already published?

Reuven Azachiproduct designer - New York

2007

A. Hi Reuven,

If any reader knows this to be covered by an extant patent and can point you to it, that would be great; or alternately if they can point to early literature to help you make a case that it is public domain, they're asked to respond as well.

But this is a situation where you probably should retain a patent attorney rather than proceeding based on an informal survey. Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2007

A. I remember a similar process in use at Engelhard (UK) about 25 years ago and I have seen jewellery made by this method on sale here.

Geoff Smith

Hampshire, England

2007

Electroforming classes/instructions in 18K for jewelry business?

RFQ: We are an established jewelry business in NYC interested in electroforming due to the increased price of gold. Could you recommend someone in the NYC area that can be of service to us in this area of expertise.

Kind regards,

jewelry - New York, New York, USA

July 20, 2011

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Electroforming the edges of gems, stones

Q. I'm interested in 24 kt gold electroforming just the edges of semiprecious stones, shells, rocks. Is there a guide that tells me which of these might react to the acid solution? Or a source that tells me what to coat the areas I don't want electroformed so they don't get acid etched?

I have a small electroforming kit that I know I can electroform the whole organic item with but I just want the edges w/ an attached jump ring for my jewelry.

thanks

hobbyist jewelry designer - Palos Verdes, California, USA

October 12, 2011

A. You can use bronze powder mixed with diluted nitro lacquer, that is simple DIY conductive paint. Paint it on parts that you want to cover, but you must know that porous precious and semi-precious stones (opal, turquoise, jade, lapis, etc.) are very sensitive, so you must protect them with some protective coating. You can find detailed description of process in any better modern jewelry making handbook (Oppi Untrachts is the best) ⇨

Hope it helps and good luck!

metals conservator - Zagreb, Croatia

Q. What kind of anode is used for 18k gold electroforming Process.

T Ranjith Kumardiamonds & jewels - Coimbatore, TN, India

October 18, 2013

A. Hi, T Ranjith. If you are buying a gold plating process, the technical data sheet tells you what to use for anodes, plus a good deal else.

If you are attempting to home brew, platinized titanium is the safest bet because they should work with any gold plating process. Technically speaking, gold as the anode would probably work -- but is unaffordable. Stainless steel anodes can be used if it's a cyanide process, but cyanide and home brewing are only for experts. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Thanks Ted for your helpful information. Can you tell me pH value for the electroforming solution I use? 15 gm of GPC and 2 liter of electroforming solution. And how to calculate the gold that coated on the mandrel, using ammeter and amp-hour meter?

Expecting your help and reply.

Thank you.

Best Regards,

diamonds & jewels - Coimbatore, TN, India

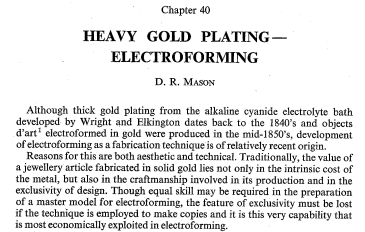

A. Hi again. If you are attempting to home brew rather than purchasing a gold plating process, I'm reluctant to offer snippets such as "ideal pH" because there are so many different baths operating at different pHs, and so many other chemistry issues, and you really need to start by accessing authoritative references like Reid & Goldie's Gold Plating Technology

⇦[this on

Amazon

or on AbeBooks --> affil links], which has a 15-page chapter just on the additional specifics involved in electroforming gold compared to electroplating, after you've already gone through the 557 previous pages about gold plating solution composition :-)

I'm not really following, though. How are you getting 18K, and what are the 6 missing karats comprised of? What else is in your solution besides GPC? Forgive me if I am misreading, but are you expecting to do gold electroforming from a bath containing nothing but GPC and water? Goldie says even the simplest also contain potassium cyanide, di-potassium phosphate, and potassium carbonate. Please see if you can find Goldie at a library and review the section on electroforming.

"Practical Electroplating Handbook"

by N.V. Parthasaradhy

⇦[this on

Amazon

or

on AbeBooks affil links] has a 9-page chapter on electroforming and, although it doesn't cover gold electroforming, there is good info on mandrels and such.

Can we please reboot this discussion -- with you answering the implied questions of whether you are purchasing an 18 kt gold electroforming process or are trying to design your own gold plating solution, and how much success you've previously enjoyed in gold plating and electroforming so we can better appreciate the context behind the questions? It seems like we're already lost in the thicket -- because you certainly don't just go out and buy GPC and start gold plating :-)

Thanks!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Ranjith, Firstly, gold deposition follows Faraday's Laws of electrolysis, so 7.35 grams of gold are deposited every ampere-hour (3,600 coulombs). Secondly, before you start electrodepositing gold from a cyanide bath, please get some professional training -- cyanide is extremely poisonous and you run the risk of killing either yourself or other people. You must use the correct safety equipment as well as have a process tank that is safe to use with cyanide.

I also suggest you buy a commercial electrolyte and precisely follow the operating instructions, otherwise you will be spending a lot of money on expensive gold solutions and not get anything to show for your investments

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

A. Sorry to disagree, Trevor, but there are other important issues.

Few gold plating solutions are 100% Faradic efficiency. Pure cyanide golds run at about 90-95% while acid hard golds are 75-80%. A home brew could be even less. This is not the solution failing to comply with Faraday but other reactions account for the missing current.

There is a further issue in calculating thickness from the weight. The density of pure gold is given as 19.3g/cc

Electrodeposited gold has a modified crystal structure and includes co-deposited organics - typically cyanide polymers.

The actual density is about 17g/cc but again will vary with the solution type.

I have electroformed gold to well over a mm and these considerations make a big difference.

I do however agree completely that home brewed gold solutions are a complete waste of time and money.

It is also true that we should be doing all we can to discourage amateur use of cyanides. Accidents give the entire industry a bad name.

Geoff Smith

Hampshire, England

A. Hello,

Just a few notes that may help with Rajith's question. There are problems that arise when using a 2 liter gold bath, especially for electroforming. This is especially true if the bath will be used repeated times. When you weigh out 15 grams of PGC there are only a little over 10 grams of gold metal in the bath. Also to be able to give an exact amount of gold deposition is very difficult because there are many factors that control the deposition rate. Some of these factors are; metal concentration, temperature, pH, solution agitation, other bath additives such as conducting salts, whether they be citrate or cyanide based. The trouble with plating with very small solutions is that the bath is taxed rather quickly and frequent additions must be made to maintain proper gold deposition rates. There are plating charts that will give you deposit rates that are close. This is why the charts have footnotes such as "at 1 troy oz metal per gallon, @ 5 ASF, and 45 or 50% current efficiency. Conditions of the bath have to be ideal to match the numbers on electroplating charts, or data thrown out there without proper "applied conditions" attached. I strongly agree with Geoff and Trevor's advice regarding cyanide.

Process Engineer - Mesa, Arizona, USA

Q. Hello

I want to do gold electroforming. Please tell me about all of materials that are used in solution of electroforming.

I am not a professional so please tell me step by step about solution and temperature and conditions of gold electroforming.

Thanks a lot.

- Tehran-The Republic-IRAN

November 15, 2014

(affil links)

free pdf is currently available from academia.edu

A. Hi Maryam.

Ideally, you should start with a hands-on apprenticeship. If that is not possible, you should start by attending a 1-week training course in electroplating. If that is not possible you must at least spend a few weeks thumbing through two or three electroplating texts to get a general feel for what is involved, interspersed with watching a few youtube videos to help visualize what is being discussed, and then ask more detailed questions. Unfortunately, the idea of someone being able to start from scratch and tell a person with no prior experience step by step how to do gold electroforming in a public forum response is unrealistic. Apologies.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

RFQ: Hello, I came across electroforming technique but it seems very difficult to get into workshops or courses on the topic, I would like to know if anybody could suggest or recommend either a service or professional in or around NYC.

Thank you,

Jewelry designer - New York, NY USA

December 27, 2014

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. Sir, please tell me what is the value of surface area for electroforming and how we get it per piece surface area -- what is the best trick?

shubham maurya- ambedkernagar,up, India

March 27, 2018

Hi Shubham. I don't actually know of truly worthwhile "tricks" ...

I've heard of people measuring the dragout from an unknown surface areas, then comparing it to the dragout from a known surface area, but there are enough complicating and upset factors, as described in Chapter 5 of Kushner's "Water and Waste Control for the Plating Shop" ⇦[this on eBay, Amazon, AbeBooks affil links] that I don't think this method is robust at all.You can also compare the current drawn at a given voltage to the current drawn by a known surface area, but again this brings complications, and would probably be useful only to someone with broad experience in that art. Employing Faraday's Law is another probably weak approach. Plating parts with electroless nickel, and weighing the deposit is still another such surface area estimation method.

Tom Rochester offers a book, "Surface Area Formulas and Tables" with a lot of helpful tabulated data and mathematical formulas, which also addresses the strengths & weaknesses of such "tricks". Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Hi Shubham

Two thoughts.

Make a guess and plate a sample. Note the time and current.

Weigh the electroform and measure the thickness. Make any correction for Faradic efficiency (acid copper needs no correction). You can then make a reasonable estimate of the surface area.

The simplest case is where the part is made to a computer designed drawing. Most CAD programs will calculate the surface area for you and any designer should print this on the drawing.

Geoff Smith

Hampshire, England

Q. Hello,

I have a little experience in electroforming (currently working with copper) and I'm trying to get irregular textures and dendrites, does anybody have any tips? I have a small 1 l tank at the moment and I'm using copper to experiment with and gain practise. Ideally I'd like to use gold but am quite hesitant for health and safety reasons ... so it may be that I create the master pieces in copper and get them cast in gold.

Thanks in advance, all the best!

MA student/jewellery designer - London, UK

September 4, 2019

A. Hi Lindy

You give us no information on your bath make up, time, temperature or current, etc.

I assume that you are using a copper sulphate

⇦ on

eBay or

Amazon [affil link] bath. Plating usually builds up on points and corners. We usually work hard to avoid dendrites but one way to get a good crop is to plate onto a bunch of bare copper wires.

What is your problem with gold plating?

You will need to use a commercial bath, trying to make your own is a recipe for expense and failure.

Most gold baths are based on the double salt potassium gold cyanide and contain very little free cyanide.

Nevertheless you need to understand any chemical process to use it safely.

You might like to read. "Cyanides in Metal Finishing, Risks and alternatives".

https://www.academia.edu/10635761/Cyanides_in_Metal_Finishing_Risks_and_Alternatives

Geoff Smith

Hampshire, England

Q. Thanks for your reply Geoff -- will have a look at reading material suggested. I know it is not usually desirable to want dendrites and texture, but I am looking to use electroforming for this purpose! I am using a copper sulphate bath (room temperature I guess?!) with V: 0.040 and A: 0.250 -- but this varies depending on size of piece etc. I am having some luck, but was curious if there are specific methods - for example - length of time or proximity to anode etc. I'm hesitant to use a gold bath due to lack of knowledge and experience, location of set up and general health and safety. So far so good with the copper wires in the bath (a good few hours now).

Thanks

MA Student/Jewellery designer - London,UK

Q, A, or Comment on THIS thread -or- Start a NEW Thread