-----

Plastic plating procedure

Q. Dear sir ,

We are doing plating for 14 years in India. We nickel-chrome, zinc plate (both cyanide zinc and alkaline zinc), copper, cadmium, tin, silver etc.

Now we are planning to do plastic plating. We don't know how to do it. Can you give me the procedure for doing it.

electro platers - Chennai, Tamil Nadu and India

2007

A. Hi Saravanan. It usually includes etching the plastic for tooth, neutralizing, dipping in palladium chloride, dipping in stannous chloride, and electroless nickel plating before the typical electroplating sequences. Copper plating must often proceed the nickel chrome plating because a soft layer is required to accommodate the differing thermal expansion between plastic and nickel plating.

"Standards and Guidelines for Electroplated Plastics" is a very good start. Alternately you can call in your supplier. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

from thread 57929:

Without the Wetting agent, Tin Sensitizer and Palladium Chloride you will not be able to coat non-conductive surfaces with Electroless Nickel.

Marvin Sevilla

- Managua, Nicaragua

Q. Marvin (or anyone else):

Could you please explain the process in detail for sensitizing plastics for electroless plating (i.e. Wetting Agent 1st, Tin for Gold, Palladium Sensitizer)? After this, you just start with your electroless nickel bath as usual?

I'm looking to plate SLA 3D printed plastics and the alternative of conductive paint is not possible due to geometry.

I've learned an incredible amount from surfing through this website over the years; thank you to all the fine contributors!

- Lafayette, Indiana, USA

May 19, 2020

(You posted this question on our thread "Formula for electroless nickel plating solution" -- probably because you appreciated Marvin's knowledge and helpfulness; but in order to maximize searchability of the site, we're striving to keep threads from wandering, and we moved your question. We'll try to let Marvin know of your inquiry)

A. Hi David! Metalizing of plastics is indeed a horribly confusing topic because there are countless ways to do it, a lot of inconsistent slang has involved over the years, there are constant new developments like direct metalization (both carbon based & metals based), and technologies like "chrome-look paint" that further obfuscate it. I think starting with an explanation of what OEMs do on their most robust items like automotive grills and why is a good way to begin, so please take a look at the intro paragraphs of thread 31550, then come back ...

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Brass plating of 3D printed plastic lamp

Q. Hello

My name is mounim, living in Denmark, I hope you can help me with advice.

I designed a lamp (approx. 22 x 27 x 25 cm), and 3D printed it in plastic (PETG), and I want to electroplate it so I can get a brass finish.

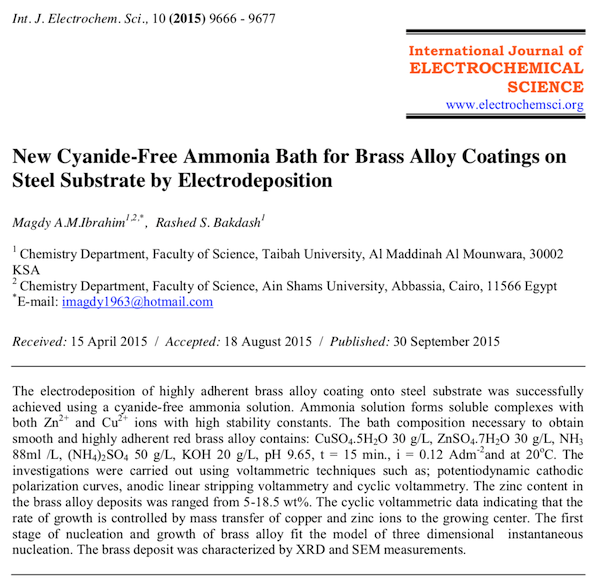

I am not sure if it is the right way to do it, but first idea is to paint it with a conductive paint (a Graphite paste) and then electroplate it so I can cover it with copper and then with zinc.

I am not sure which electrolyte to use (preferably cyanide-free), and how much I need.

How many times can I use your/the electrolyte solution?

Please: any suggestion?

Thank you.

- Copenhagen, Denmark

June 3, 2020

A. As far as I know only one USA firm sells cyanide free brass plating solution. There are many cyanide free brass plating expired patents and science based articles too. Plating on plastic is not simple process.

Try leaf gilding (or imitation gold leaf). Hope it helps and good luck!

Goran Budija- Zagreb,Croatia

Q, A, or Comment on THIS thread -or- Start a NEW Thread