-----

Titanium-Cadmium Plating Q&As, Problems & Solutions

Cadmium is a biocumulative poison like mercury & lead, and should be eliminated/substituted for when possible. However, cadmium plating offers a host of beneficial properties including cathodic protection, malleability, freedom from sticky corrosion products, lubricity, and compatibility with aluminum which no other material exhibits.

Usually you need only *some* of these properties -- and which ones you need guides the substitution process. If you need *all* of cadmium's properties, no substitute is possible, so there are still legacy applications, particularly in life-critical applications like aerospace.

One potential problem with cadmium plating (and most plating) is 'hydrogen embrittlement' ⇦ huh?. Generally, immediate baking is done to try to drive the hydrogen out. In the specific case of cadmium plating, it has been found that incorporating a small amount of titanium into the plating creates a porosity in the plating which helps the hydrogen escape during baking rather than being impeded from escaping by the integrity of the cadmium plating layer.

Q. I need your help.

Please note that the Ti concentration in the plating bath is 75 ppm but weight percentage of Ti in the plating is 0.17% (plated on copper foil based on Boeing procedure).

Can you help to how to increase the Ti weight% in the plating?

Regards

Montreal

October 1, 2024

A. I was surprised to realize that it has been 15 years since I have run TiCad, but it is very hard to forget the effort that went into controlling titanium content. In my old 2004 version of BAC 5804, the control limits of Ti is 55-97 ppm in solution ---OR--- 0.1 to 0.7 % in plate. Your 75 ppm is nearly optimum. Your plate % is a bit on the low side but it is okay. I personally would not be concerned that Ti is too low.

I will share what I used to do for Ti concentration...

If you need to get Ti ppm higher, then it is just a matter of getting the peroxide and Ti-paste right. I preferred to add Ti paste additions manually by pre-dissolving about 300 grams in a gallon or so of peroxide (carefully!) then just pouring it into the tank on a batch basis. On the tank, a very slow peroxide on a continuous feed is best. I used small-bore variable speed peristaltic pump for that and would adjust the feed rate as needed to keep the titanium soluble. For me, I found that 400 mL per 24-hr day per every 1000 liters of cad solution was about perfect, but it would depend somewhat on your bath temperature. Controlling it this way is far better at maintaining the concentration of titanium compared to the method that has you slurry-coat Ti-paste onto filters.

Jon Barrows, MSF, EHSSC

Kansas City

Q. HI

Please note that if Celatom FW-12

⇦ huh? dissolves into TiCad solution, is it affecting the plating? We have some sludge on the high current density areas which does not let the conversion coating absorb. Also I did not find any standard procedure for hull cell

⇦ huh?

for this solution,

I appreciate the experts to comment

- Montreal

May 6, 2025

A. Hi Houman.

Although you could be right that the diatomaceous earth filter aid is dissolving into the plating solution and being attracted to and deposited on the high current density end of the Hull Cell panels, I am not seeing the mechanism that would attract it there, so I am not convinced that this is what is actually happening. Have you actually done an analysis showing that the 'sludge' is a filter aid byproduct rather than being titanium particles, burning of the plating, etc?

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thanks Ted, I am trying to lower the Ti ppm (from 87 to 60) in the solution and test Hull cell to see if the situation changes or not.

Thanks Ted, I am trying to lower the Ti ppm (from 87 to 60) in the solution and test Hull cell to see if the situation changes or not.

- Montreal

Q. Hi

Please note that always we see the titanium powder on high current density areas of CRT panels (edges), if we do not clean this powder manually (light wipe) then chromate conversion will not be absorbed and SST will fail at edge with red corrosion, is that normal?

- Montreal

May 20, 2025

A. Hi again, Houman.

Although I have a general understanding of ti-cad plating and have watched it being done for a few hours, sorry, but I don't have experience maintaining or troubleshooting the process and can't answer your question, so we'll have to hope for input from someone with more experience on this.

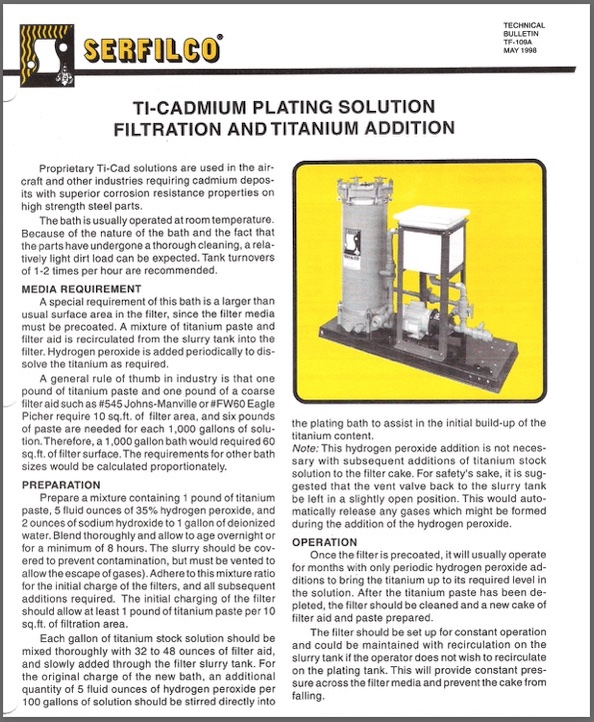

Still, powder on the parts might indicate that you have a filtration problem, so while waiting, please review your filtration methodology against this advice from Serfilco ⇨

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇩ Related postings, oldest first ⇩

Q. Does anyone know the benefit of using a titanium-cadmium coating in place of a cadmium coating? If possible I would like references to actual data. We are in the process of eliminating the majority of cadmium plating requirements from our parts. Unfortunately we have several parts which require a titanium-cadmium coating. Before we eliminate this coating we are trying to understand why it was specified over cadmium in the first place. Any help that can be provided will be appreciated. Thank you.

Blair Smithaerospace - Windsor Locks, Connecticut

1999

? Could you be referring to chemical vapor deposition of titanium carbide or some other of the new coatings being touted as a replacement for Cd plating?

Best regards,

Tom Pullizzi

Falls Township, Pennsylvania

Q. Tom: I actually mean cadmium-titanium plating. This coating is covered by AMS2419. Thank you for your response.

Blair Smith [returning]aerospace - Windsor Locks, Connecticut

A. Hi Blair

Titanium - Cadmium plating was developed by Boeing as an alternative to many other coatings that supposedly offer no hydrogen embrittlement. For the real inside info call Dave Kelly at ASCO products in Seattle; he has a bath and often installs baths and trains operators; and as far as I am aware he is the ONLY approved source of the Titanium additive.

regards

John Tenison - Woods

- Victoria Australia

Ed. update: We believe there are currently 3 approved suppliers of the titanium paste, but your Boeing buyer can provide an authoritative answer.

A. Thread #3575 mentions TiCad plating and another specification number.

Tom Pullizzi

Falls Township, Pennsylvania

A. I believe the primary benefit of TiCad over Cad is lower susceptibility to hydrogen embrittlement. Apparently Titanium affects the grain size of the plate and thus the ability for hydrogen to escape in post plating baking operations. I am not aware of any data to support this, although I believe people in the Boeing Materials Group did a lot of the pioneering work in the 1960's. We have performed Cad and TiCad plating in this facility for about 10 years.

Q. I am curious what process you are changing to and the data you have to support those changes. The aircraft industry has historically been reluctant to remove cadmium plate, but we would entertain moving away from it also.

John Peaseaerospace - Shelby, North Carolina

by Abner Brenner

on eBay or Amazon

or AbeBooks

(affil link)

![]() Thanks John.

Thanks John.

I've been in your plating shop and well understand that with your rigorous safety protocols (wearing a respirator, for one), cadmium plating is something you'd like to get away from if possible. I may be in error, but I believe Ti-Cad is not an alloy of Titanium and Cadmium, but a composite coating where the tiny titanium dust particles are co-deposited and entrained in the cadmium plating.

Brenner leans toward it being an inclusion rather than an alloy. If a lab guru could clarify for us, facts trump theories.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Shops that do Ti-Cad plating

Q. Please provide any information on vendors (job shops) that perform Titanium-Cadmium plating per MIL-STD-1500.

Phil DeMauroactuation systems - Whippany, New Jersey

1999

A. The following are Boeing approved sub-tier suppliers who perform Ti/Cad for aerospace applications.

- USA California CROWN CHROME PLATING INC

- USA California DRILUBE COMPANY

- USA California EMBEE INCORPORATED

- USA Kansas AIR CAPITOL PLATING INCORPORATED

- USA Michigan DIAMOND CHROME PLATING INCORPORATED

- USA North Carolina CURTISS WRIGHT FLIGHT SYSTEMS

- USA New York LAWRENCE RIPAK COMPANY

- USA Ohio BFGOODRICH

- USA Ohio NUCLEAR PLATING INC

- USA Oklahoma SOUTHWEST UNITED INDUSTRIES INC

- USA Texas MENASCO AEROSPACE TEXAS

- USA Washington ASKO PROCESSING

- USA Washington HYTEK FINISHES COMPANY

aerospace - Wichita, Kansas

Multiple threads merged: please forgive chronology errors and repetition 🙂

Cadmium vs Zinc Electroplating

Q. In general, which plating process introduces the most hydrogen into a high-strength steel part: Cadmium electroplating or zinc electroplating? Is there a significant difference? In other words, which process poses the most risk for hydrogen-assisted cracking in the future?

Marc PepiUS Army Research Lab - APG, Maryland

2000

A. Neither standard bath is highly efficient, so both introduce the problem. Baking is the usual relief process, but some people who know more material science than I do say that the cadmium or zinc plating entraps the hydrogen so it can't easily get out.

Perhaps your best bet is a low embrittlement cadmium plating process, one which has pores to allow the hydrogen to escape. One I'm familiar with is Boeing's TiCad process; a small amount of titanium is co-deposited and entrained as a powder into the bath and, when plated, it makes the coating porous.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Both of the above replies are correct in many respects. First it should be noted that the preplate cycle can cause hydrogen adsorption both from acid pickling and if cleaning is done with the work anodic (not preferred). Secondly, chloride zinc plating, because it has a much higher efficiency, tends to have less embrittlement from hydrogen; however, frequently the deposit itself is brittle!

Gene Packmanprocess supplier - Great Neck, New York

Multiple threads merged: please forgive chronology errors and repetition 🙂

Embrittlement from high speed cyanide cadmium solution

Q. We are cyanide cadmium plating a high strength 8740 alloy bolt (Rc50). I am investigating ways to reduce the amount of hydrogen in the part after embrittlement baking ⇦ huh? . Our current process uses 2.1 oz./gal cadmium and 15 oz./gal sodium cyanide. Our embrittlement bake is 375 °F for 72 hours within 1 hour of plating. We have looked at the "usual suspects" for embrittlement already, brightening impurities, time to bake, no acid processes, etc. We grit blast, rinse, cad plate at 5-10 ASF. Has anyone used a high speed cyanide solution (Cd 4.5 oz/gal, CN 9 oz/gal) for barrel plating of high strength steels? Was there any improvement in embrittlement vs. a standard cyanide solution? Does rack plating embrittle less than barrel plating?

Thanks for your assistance.

Brad Waltersplating shop - Huntington Beach, California, USA

2004

A. Please search the site for TiCad plating, Brad. This is a cadmium plating bath that has a tiny dispersion of titanium particles in it which causes the cadmium deposit to be porous and more permeable for the escape of the hydrogen.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Ted. I neglected to mention that the customer requirement is AMSQQP416, which doesn't allow Ti-Cad plating.

Brad Walters [returning]Captive shop - Huntington Beach, California

Spring Plating

Q. I am fabricating a spring from steel music wire and would like to know if the following finishes will change the properties of the spring, such as the spring constant and if it will make it brittle, specially the CAD plating, which requires heat.

1- Steel Wire Cad Plated

AMSQQP416 Type II Class 2

1- Zinc Plated Music Wire

ASTM B633 Type II

Aerospace Engineering - Wellington, Kansas, USA

2005

A. There is no substitute for a good set of reference books if you are going to do engineering, especially aeronautical.

You will find that there will be some reductions in the original preplated parts when they are plated. A post plate bake is mandatory for either material. This bake is below the tempering temperature of the rod, so you will lose no more than 1Rc.

If the plating is done very well, I seriously doubt that you could measure the difference unless you have a great lab.

If you do not want to bake, use mechanical plating. No hydrogen embrittlement (unless you acid etch).

- Navarre, Florida

A. Both of those electroplatings (and their pretreatment steps of cathodic cleaning and acid pickling, if applicable) will cause hydrogen embrittlement. Proper baking for hydrogen embrittlement relief immediately after plating is essential.

There is a low embrittlement cad plating that co-deposits a titanium oxide slurry to provide paths for hydrogen escape. It's sometimes called Ti-cad. Sorry I don't think it complies with the AMSQQP416 you are using.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

White spots under Ti-Cad plating

Q. After a Ti-Cad treatment we received back some parts with some white "spots" under the surface. I read on

thread 26828 that the Ti-Cad plating

"keeps the deposit from being continuous and allows the substrate to "breathe" to reduce hydrogen embrittlement".

Is there the possibility for which the more "porous" surface permits the humidity air penetration and this phenomena leads to some white spots "underskin"? May this be considered corrosion?

Or could it be a bad surface preparing process during the plating?

Thank you

Plating shop employee - Italy

September 28, 2009

Can filtering cause hydrogen embrittlement in cadmium plating?

Q. Can a filtering issue in a cad tank contribute to hydrogen embrittlement? Or, will changing/cleaning the tank filter substantially change embrittlement testing results? I can see how filtering may impact adhesion, but I'm not certain how hydrogen embrittlement may be affected. Thanks.

Rob Ogden- Jamestown New York USA

March 21, 2016

A. Hi Rob. I don't see why filtering a straight cadmium plating bath should reduce hydrogen embrittlement. On the chance that you have a Ti-Cad bath, though, we appended your inquiry to a thread on that subject. (In Ti-Cad plating, a slurry of small titanium particles is used in the cadmium plating bath. My understanding is that they are occluded into the deposit in a similar fashion to the way diamond particles are occluded into the nickel plating of tools; they offer an improved "ventilation" so that hydrogen can escape better. If you were to filter out the titanium particles, presumably you could cause a hydrogen embrittlement issue).

Please try to describe the situation as fully as you can to 'filter' out the ifs, ands, & buts as much as possible :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. We use a sodium cyanide cadmium process, not TiCad. We test for hydrogen embrittlement monthly, per ASTM F519. Recently we had a cad plated hydrogen embrittlement test specimen fail at over 100 hrs into the test. The remaining three specimens all passed the 200 hrs requirement, and were then subjected to the additional step load test. One additional specimen failed .1 hours after reaching the 90% NFS threshold. Specimens from the same specimen lot, from our other processes, went through the bake with the cad specimens and these all passed the 200 hr embrittlement test. The operator suggested after the fact that the tank filter was dirty, and needed changing. Hence, my original question: Could/Would a dirty filter/clogged impact hydrogen embrittlement. Thanks.

Rob Ogden [returning]- Jamestown New York USA

A. Hi Rob,

Just going to ask for a couple of clarifications: the test pieces went through de-embrittlement (also called embrittlement relief) at the same time and temperature as the other test pieces? 1 off failed the load test at 100 hours and a further 1 failed at the higher load?

So places to look, as I don't think filtration of the cadmium plating tank is the problem (but don't discount it completely).

1. Are the test pieces flaw free? I had a problem a number of years ago where the test pieces suddenly started to fail and it turned out a new person was machining them, but was machining in a flaw, causing premature failure.

2. Check your de-embrittlement time and temperature and also the delay between plating and getting the test pieces in the oven. Again, mystery failure of a one off bath load a few years ago turned out that the operator missed the maximum delay time to get the parts in the oven and the embrittlement damage was already done, part failure was very rapid I must admit (less than 24 hours).

3. Check all of the pre-treatments. An electrolytic cleaner can actually cause test failures. Look at immersion times, chemistry, voltage (for electro-cleaners) etc.

4. Check your cadmium plating tank chemistry, plating rate, times and temperatures.

That should get you started in trying to identify the source of the failure.

Aerospace - Yeovil, Somerset, UK

Q. Help please CAD gurus!

For TICad plating on HSS (Aircraft MLG) ... is there a rule of thumb for permissible (localised) damage to cad plate ? E.g., size /area ratios /duration?

Due to size and location (and crap OEM design/ with clashing so damage will reoccur if touchup surface) localised touchup using LHE brush cad is not practicable.

Concern is possible hydrogen re-embrittlement at the exposed base metal (HSS). CAD plate is sacrificial but at expense of H creation at base metal (there is a Cranfield paper about this )...I suspect this is not a big deal if we keep base metal protected from moisture (i.e., source of H).

Aerospace maintenance support (engineering) - Queensland Australia

October 27, 2018

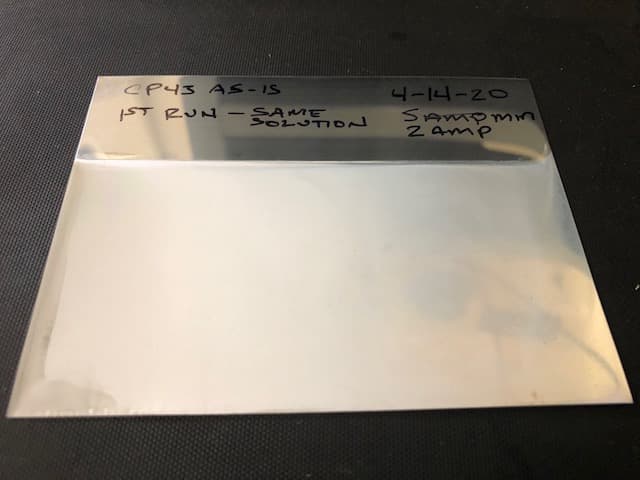

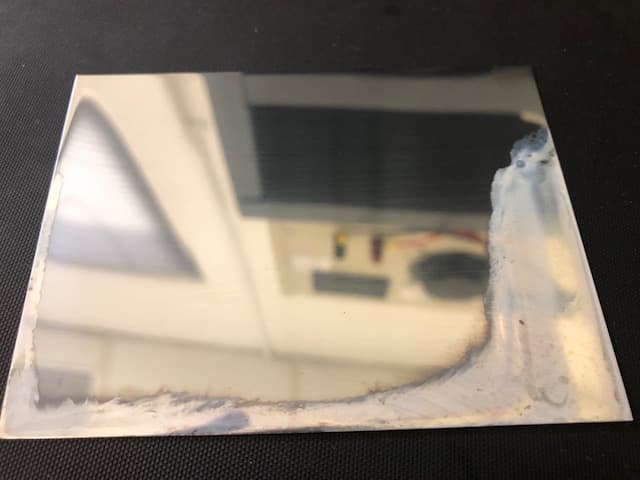

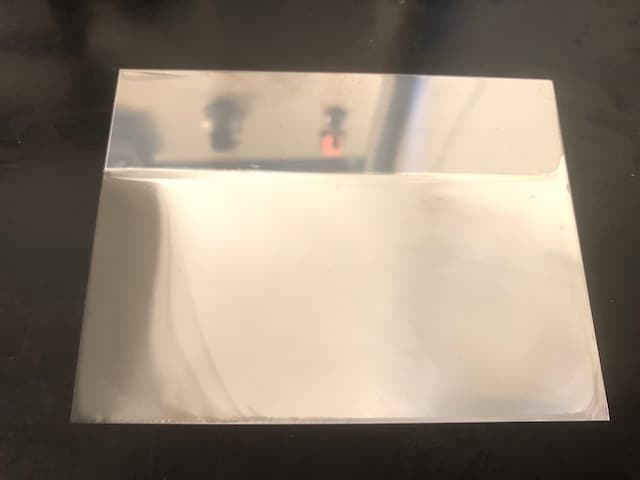

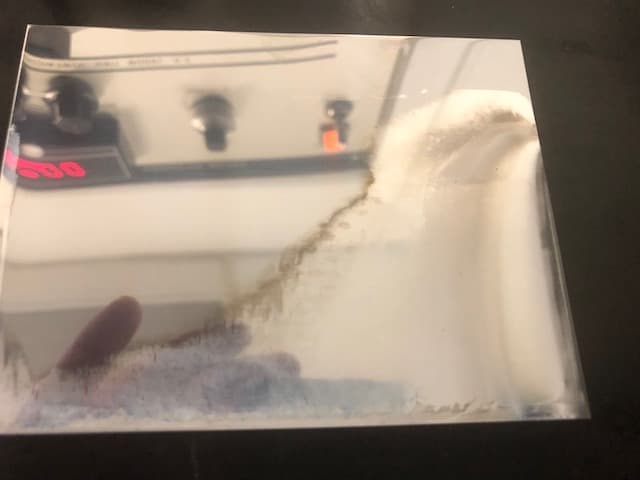

Rough Titanium Cadmium plate

Q. We have recently carbon treated our TiCad bath. Our plating finish on the parts is rough on our test panels. To confuse even more the ID on a part has a combination of rough and "perfect" smooth finish. Our Hull Cell panels (2 amps, 5 minutes) look nice. The HDI will also not pass now. Any and all help is appreciated.

- California

April 16, 2020

? Did you find what the problem is? And if so, how did you solve it? I am attached to the situation.

ella epstein- ISRAEL

March 27, 2023

by Terrance H Irvine

on eBay or Amazon

or AbeBooks

(affil link)

by Langford & Parker

on Amazon

or AbeBooks

(affil link)

Q. How do we find out the Titanium content in Titanium-Cadmium electroplating solution? (Chemical analysis method)

Looking for the filter which allows the Titanium content back to solution? (Brand name/Model/Technical specification)

Aerospace - Bangalore, INDIA

April 23, 2020

Ed. note: Technical specifications are welcome but we can't post suggestions of brand names or sources (huh? why?)

Q. Did you find the answer to the question? I'm facing the same problem.

Titanium is currently analyzed by ICP and Spectrophotometer. However, there is no difference in titanium concentration before and after hydrogen peroxide add. I don't know how to analyze titanium dioxide used for Cad-Ti plating.

Also, we used 500 microfilter filter cartridges, but titanium is filtered.

- SACHEON, South Korea

A. I assume that you are doing work on Boeing parts per BAC5804. Their specification has the test methods for measuring titanium in solution and also titanium in the plate. The methods are a bit complicated, but they both require a spectrophotometer ⇦ on eBay or Amazon [affil link] to measure the end result at 420 nm.

Jon Barrows, MSF, EHSSC

Kansas City

Q, A, or Comment on THIS thread -or- Start a NEW Thread