-----

Rainbow Titanium / Stainless Steel Coatings

Q. I am trying to find out if there is any passivation method for stainless steel that produces an iridescent yellow finish similar to a zinc yellow dichromate. I've tried looking in all of the specifications I could find but I haven't found anything. Anybody?

Ruth ZelayaMaintenance Services - LIC, New York

2001

A. Hello Ruth!

Well, I've never seen one, and I don't think that standard chromate treatments like Alodine will stick to stainless steels: but I'm not sure that means they can't exist. My cynical nature would be aroused by such an observation, and I'd suspect I might have been given a plated rather than a passivated part, especially if this is on a small, common, commercial item like washers or fasteners. Any way you can do a quick analysis? Even grind off the yellow, and try copper sulphate, or use a magnet if the stainless part was supposed to be non-magnetic, might tell you something.

Write back with more info, and I'll reply more...

Good luck!

Lee Gearhart

metallurgist - E. Aurora, New York

2001

adv.

We decided to spend some time investigating this problem, and after a month of research and testing developed the process of color passivation for stainless steel. We can produce yellow, gray, brown, blue, and other shades.

Besides color, this method increases corrosion resistance due to thick passivating film. The process is ecologically clean.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

2001

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am experimenting producing simple flutes out of titanium tubing, grade 2 tubing to be exact. I am aware of two methods that are used to create colors on the finished product. One technique was applying heat with a pure flame and the other involved electrocuting the material in water. The processes are of course more involved than this. I do have a few questions. Which techniques provides better results? Is my grade 2 titanium tube suitable for this application? I really would appreciate any feedback on this subject.

Regards,

flute maker - Houston, Texas

2003

A. We appended your inquiry to a thread about anodizing titanium to get the rainbow / "oil slick" look.

silly If you phone a spa about an electrotherapy session for your wife, choose your words carefully or make sure the police aren't recording the call :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2003

A. Using the electrical method you can produce a much wider variety of colors much more consistently. The drawback is that the finish is just decorative and will wear off very quickly. Color is controlled by the voltage run through the piece..the higher the voltage the thicker the coating and the longer it will last but even the best lasting will wear off very rapidly. In the jewelry we have made using this method it has worn off in as little as 2 weeks and as long as 2 years (rub it on your jeans for a few minutes and it will come off).

Using the flame method the colors are harder to control and not as bright, but will last much, much longer. We have customers that have had pieces for 5+ years with little wear..but keep in mind these are mostly earrings that are subjected to very little wear. To keep the colors as vibrant as possible use a very clean flame. In either method make sure the piece is completely clean. Any oil etc will show up after anodize. just out of curiosity why titanium? why not aluminum? much cheaper and colors will last MUCH longer.

- Flint, Michigan

2003

2003

RFQ: Hello,

I need to find someone that can do Titanium -oxide coating on Paintball Guns. They are mostly 6000 series aluminum. This is exactly what I am looking for:

Thank you,

Donovan Bailey- Charlottesville, Virginia

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

2005

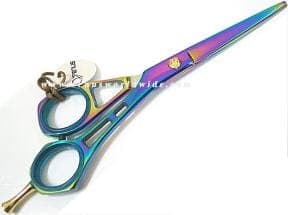

RFQ: I am just looking for the process of Titanium Coating on the stainless steel parts like Scissors, Pluckers for the decorative purpose the resultant product is in different shades like green, yellow and blue all mixed giving a decorative impact. I am desperate about this -- is there anybody to answer my question?

I am attaching a picture, and this is assumed to be the Titanium coated I am just looking for this process these colours are deposited/plated?

I am ready to buy this set up if the results are satisfactory

- LONDON, UK

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Dear Ashan!

Stainless steel can be colour anodized.

It can be heat tinted too.

Hope it helps!

- Cerovski vrh Croatia

2005

![]() Hi. Goran is surely right about what can be done ... but I don't think that is what was done to these particular scissors. I think they have a titanium coating which has been anodized.

Hi. Goran is surely right about what can be done ... but I don't think that is what was done to these particular scissors. I think they have a titanium coating which has been anodized.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear/ Madam, Hello

We are razor scissors manufacturers. We are interested in multi-color on stainless steel scissors. Please advise, How can we coat titanium on stainless steel for multi-color finish.

Thanks and best wishes,

Sky Instruments - Sialkot, Pakistan

2006

A. You cannot commercially electroplate titanium, but you can use PVD deposition to get varied colors such as titanium nitride (TiN).

James Watts- Navarre, Florida

2006

Multiple threads merged: please forgive chronology errors and repetition 🙂

Rainbow Finish on Stainless Steel

Q. I am looking for the process to provide a rainbow-like finish on stainless steel.

I am helping with the design work for a project - a religious shrine, that would like to incorporate a stainless steel arch that has this type of finish on it. I had found a website of a particular fabricator, that talked of a chromic oxide process. The client representative had something described to her as a finish that is likened to overheating the stainless steel...I've seen similar finishes on copper, but never on stainless steel.

What is the durability of the finish and I'd also be interested in an actual sample or image of a finished piece of stainless. This is for an exterior application.

Thanks!

John R. Keiser

architects - Pittsburgh, Pennsylvania

2006

A. SS will oxidize with heat in an air or oxygen rich environment. To get it to rainbow, you need different amounts of heat for each color, so I will guess that it will take a torch or other point source of heat. You will have a hodge-podge array of oxides of the materials in the alloy, namely iron, nickel and chrome.

Yes, they are very very durable.

- Navarre, Florida

2006

Want titanium-like rainbows on something else for kitchen backsplash?

August 19, 2009Q. I'm redoing the house for my mum. My dad died when I was 19 and was terrible at D-I-Y anyway. Since then, nothing has been done. So it's in DESPERATE need of a complete strip and refinish.

We need a splashback to surround the whole kitchen. The new kitchen will be incredibly plain and bright white, since estate agents told us that's something a lot of people make mistakes with - personalizing the house and dating it way too obviously.

But I wanted to inject some a least a little of my own personality into it in a more removable form. The units are white because the kitchen is quite dark. We'll have a surface running around almost the entire perimeter.

I'd really love to add either a mirror polished copper splashback (sealed to prevent tarnishing) or something like the rainbow pattern of anodized titanium. The copper is easier to do. But the rainbow is exciting.

First of all, I can't imagine getting titanium sheet that long will be cheap (possibly comparable to copper) and secondly, I don't know where I could get one big sheet dipped. Maybe I could have it chopped up into tiles and do each one individually, but VERY busy on the eyes over a large area. And even I have a limit with that; I don't want to get lost in my own kitchen.

Are there any other metals or processes anyone can suggest for creating a long, continuous titanium style rainbow?

Thanks, your help is much appreciated with this one!

John

- Liverpool, North West, UK

A. Hi John. There are now paints and such which offer at least a multicolor look if not the full "oil slick" look. Please see thread 7352.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

July 10, 2012

Q. How to get coating of titanium on stainless steel? I have viewed rainbow shades on the scissors, which is called the titanium coating.

Luqman Rafiq- Gujranwala, Pakistan

A. Hi Luqman.

The coloration is actually a diffraction pattern similar to what you see in carnival glass or the rainbow sheen of a drop of oil on a puddle of water. It results because the titanium oxide layer on the surface is transparent and of varying thickness, so part of the light bounces off the top of the titanium oxide coating and part bounces off the bottom, and they interfere.

My understanding is that the titanium is applied to the stainless steel with a PVD process, then the coloration is done by anodizing the titanium to varying thicknesses by controlling the immersion depth, time and voltage.

But the people who have invested years of effort in developing this process and are now profiting from its popularity aren't going to simply give us the whole technology for free as a package. You probably must find someone who is licensing the technology, or retain a consultant who is experienced in it, or glean pieces of it from here and there (as I'm doing), then invest effort to perfect it. Best of luck!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

July 10, 2012

October 24, 2012

Q. I had some questions about using a titanium coating (probably by Titanium Nitride) to get vibrant colors on stainless steel spinner rings (jewelry).

Question 1: Is the coating durable? People will be spinning the rings frequently by hand.

Question 2: I want to make a 2-tone ring. Can I do a black base coat, laser engrave/remove the surfaces I want to be a different color, and then do a second coat in a brighter color, say green? Or will the new color just overwrite the black and create an all-green surface.

I look forward to your feedback.

-Aaron

- Silver Spring, Maryland

Aluminum Rainbow Plating Question

Q. Hello, I've been searching around for a while on information on rainbow plating and who can do them for individual customers. I'm a paintball collector/player, and have learned about Rainbow plating through my fencing coach. He had blades that were done in this process. From what I've gathered it can be done on aluminum, but I'm curious to know how the finish will turn out, and if anyone could point me in a good direction for a good plating company.

Thanks for your time and responses,

hobbyist - Sacramento, California, USA

2005

A. That finish is done on titanium via anodizing. Although aluminum can be anodized, it is a very different process than titanium anodizing and I don't think it can be made to exhibit quite that rainbow color, although another pattern called "splash anodizing" is widely done on paintball guns. A third technology you might consider for fancy coloration is "water transfer printing".

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2005

A. Highly polished aluminum can be chem filmed and have a wide spectra on colors. Poor wear resistance and corrosion resistance.The paintball folks use a lot of masking and dying, but these are normally sharp demarcations. Rainbowing can be done with inks and air brush. Differential dying will give a wide variation in color, but certainly not with the iridescence of the titanium anodizing.

P.S., The precise methods are extremely proprietary, thus not published and thus a lot of trial and error.

- Navarre, Florida

2005

Rainbow finish on butterfly knife

Q. I am hoping to buy a UK legal training butterfly knife (has no edge or point, so not considered a knife) and it is steel with a "spectrum oxide finish" and it basically looks like a rainbow with mainly purples, greens, etc. in the colour as if water is put on an oil slick...

![]()

I just want to know if this is easily scratched, or worn off due to rubbing on joints or impacting another surface. any help will be great. thanks.

product designer - New York

May 30, 2008

Multiple threads merged: please forgive chronology errors and repetition 🙂

Want rainbow titanium dioxide finish on golf clubs

RFQ: Hi, I am after getting a golf club finished with rainbow titanium dioxide, I am based in the UK.

Contact me if you can do this or know if it can be done D-I-Y.

Thanks

golf - Greenhithe, Kent, UK

July 27, 2009

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi, Warren. It can be done D-I-Y if you can't locate a shop, but some skill and practice may be necessary.

The decorative coloring on titanium is actually a diffraction effect, similar to carnival glass or the rainbow sheen from a drop of oil on a water puddle. The titanium dioxide is essentially transparent, and by anodizing in a mild solution of TSP or Coca-cola, you can make the clear coating thick enough to generate various colors.

I believe that if you skillfully and repeatedly dunk a titanium golf club head into the solution and lift it partially out, the area that is immersed all the time and at a higher current will form a thick coating, while the top end, which is only in solution a fraction as long, will have a thinner coating. With skill, I believe you can get a smooth rainbow gradation. Haven't done it, and am not saying it's easy :-)

Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

July 9, 2010

RFQ: I want to do rainbow titanium nitride finish on my Glock slide. Does any one know someone that does this?

Jim Wanger- Clackamas, Oregon, USA

November 22, 2010

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi, Jim.

I think you may be somewhat mixing apples and oranges when you first call it "titanium nitride coatings" and then say "rainbow titanium finish". To my knowledge, titanium nitride is a gold-tone hard finish applied by PVD processes and usually to steel parts, whereas rainbow titanium finishes are an anodizing process performed on titanium alloys or titanium coatings. I don't know much about Glocks -- what metal is the slide made of, steel or titanium?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

November 22, 2010

'Rainbow Chrome'/'Oil Slick' finish on Aluminum alloy bicycle parts - options needed

August 22, 2015Q. I have a custom aluminum bicycle frame that I had built up, and I would like some suggestions on achieving a certain finish to this frame, and, along with it, smaller components to the overall build which will also be aluminum alloy.

The finish I'm looking for has been referred to as an 'oil slick' or 'rainbow chrome' or 'full spectrum chrome' and it's often used on BMX parts that are steel. It is was also used, in a very rare instance, on a BMX frame (again, steel) in the attached image. The situation I'm facing is a bit different - Aluminum parts, the frame is larger (envelope described below), and weight is a concern.

Factors to consider in the finish:

-Minimal mass gains after the finishing process. Ideally there should be virtually *no* weight gains. Weight matters here for everything.

-The finish needs to be durable... scratch resistant, definitely UV resistant to fading.

-A multi-step process is fine, and even if it's remotely possible, can a finish be achieved through a D-I-Y home kit (I have an architectural background as well as a degree in the sciences, I know my way around chemicals and a workshop)

The research I have done has lead me to a PVD coating process, however my inquiries to a few service providers has been mixed. One was outright terse with a "no, it can't be done' whereas another wrote a great response explaining that the frame is too large for their machine and I would have to get the frame chrome plated first - (which means more weight which is something I do not want.)

Can anyone here offer some ideas on what method I need to take to achieve this finish on a bicycle frame and a few bicycle components (everything is aluminum alloy, everything can be cleaned to bare metal and polished)? Can any of these suggested methods allow for masking techniques? What about UV protection from fading or corrosion?

Bicycle Frame envelope - 37-1/8" x 21" x 6-1/8" or 935 mm x 523 mm x 155 mm

Other parts are much smaller ... Rims, if possible are 622 mm x 622 mm x 25 mm

Thank you,

Designer - Los Angeles, California

A. Hi Alex. My understanding is that this finish is obtained by a PVD deposit of titanium onto steel, followed by anodizing of the titanium, with both operations performed by single shops which have developed the technology to do it.

If you demand exactly this finish, you have a very difficult road in front of you. Most plating shops can't chrome plate aluminum because it requires special zincate chemistry. After the zincating and nickel-chrome plating you have to find a PVD coater to apply titanium to the chrome plated aluminum. Then you have to find a titanium anodizer to anodize it to this oil slick appearance. One of the three shops, if not two or all three, will lack the requisite experience and can surely be counted on to hopelessly screw it up.

I think you should try to talk yourself into "splash anodizing" which is done on aluminum, or "water transfer printing" / "cubic printing" which is done with paint on aluminum. Neither looks like this oil-slick finish, but they do look unusual and good. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August 2015

A. Alex

It might be easier if you start with a titanium frame.

- Colorado Springs, Colorado

August 25, 2015

A. Titanium dioxide can be coated onto various metal substrates, especially stainless, and it is possible to control the colors. The multi-color or rainbow effect is also possible but will require some basic understanding of the deposition process.

The coating is durable for most applications.

process development engineering - San Diego, California USA

May 19, 2017

Q. What metals or materials can I apply rainbow coating to?

I am looking to make a Crowbar rainbow coated for a friend.

- Erlangen Bavaria Germany

June 22, 2017

A. Hi Lukas. This process applies to titanium. But applying the titanium onto steel requires an expensive PVD chamber not well suited to onesy-twosy applications. It might be more practical to make the crowbar out of titanium, then try to anodize it for the rainbow effect.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 2017

Zinc Passivation for Rainbow Colors?

February 5, 2018Q. Hello

I have been going around to my local electroplaters to try and work out how to achieve the finish like the photos I have posted. I would think that it is some kind of Blue Zinc passivation but no one can seem to be able to achieve the finish. I would love any help.

Artist - Melbourne, Victoria, Australia

A. Hi Michael. Whenever we see a "rainbow" or "oil slick" coloration, it's almost a sure thing that the color is not from pigments, but from a diffraction coating (transparent/translucent coating of partial wavelength thickness which generates interference patterns), much like a drop of oil on a puddle.

It may be possible to do this on zinc, and it may be possible to do it with chromate conversion coatings, but I have never heard of it. I think it's more likely that the component is anodized titanium or possibly has a thin coating of oil on it that has been dried with a torch to different thicknesses, i.e., "flame colored".

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2018

Ed. note: This thread focuses mainly on iridescent/rainbow/"oil slick" coatings on titanium and stainless steel, primarily by anodizing titanium to create transparent partial wavelength titanium oxide coatings.

It is also possible to apply lacquer, oil, or metallic salt coatings to achieve similar looks on other substrates without titanium anodizing; thread 7352 focuses on that.

Q, A, or Comment on THIS thread -or- Start a NEW Thread