-----

Tube module settler vs lamella plate clarifier

Q. Dear Sir,

I wanted to know among plate settler and tube modules type of clarifier which one is better. And could you tell me the advantages of each, comparing the two.

Thanking you in anticipation.

Ronny Fernandes- Mumbai, Mahrashtra, India

2004

Q. Hi,

I was wondering if there are any responses to the raised question. I would like to have more information in this regard as well.

Thanks!

- Davis, California

2006

A. What happens in a plain clarifier (with no lamella plates or tube modules) is this: the water flows into the bottom and out at the top, and you make it so big that even though the descent rate of the tiny floc particles is very slow, the rise rate of the water is even slower, so the particles settle to the bottom.

The theory behind both a tube settler and a lamella unit is very similar, with this change: Although the water rises as before and the particles settle as before, the water is flowing inside a tube or channel that is set at a 45 degree (or so) angle. The water will have to travel several feet from the entrance of the tube to the exit, but particles will only have to fall a couple of inches before they hit the bottom of the tube or plate and start agglomerating -- so the size can be greatly reduced.

The theory more or less works, as witness the countless lamella and tube settler clarifiers installed. So the thing really becomes a matter of convenient geometry. Tube modules less than two foot deep can fit into a round or rectangular tank in a reasonably small space whereas long lamella plates set at an angle must go into a funny shape tank which, viewed from the side is, instead of a rectangle like a building, a parallelogram slanted at the 45 degree (or so) angle.

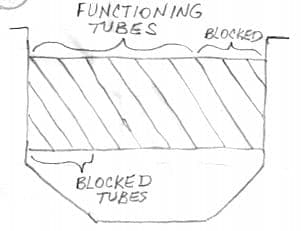

All things being equal, and with enough room, I'd probably go with the lamella plate because the plates can have real mechanical integrity whereas the tube modules I am familiar with were usually flimsy thin plastic boxes. But finding installation height for a lamella settler can be tough. The lamella is all usable area because the tank walls and the plates are parallel. But the tube settler has dead area because any tubes near the wall are dead ends, so very small diameter tube settlers won't work -- they need to be fairly large diameter (or large rectangles) so the percentage of dead space is minimized (Picture a two-foot deep 45-degree tube module in a two-foot square tank: water could not flow at all because every tube would be a dead end with one end or the other running into the vertical walls of the tank.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2006

A. Tube settlers are based on different theory that states that settling is dependent on settling area rather than detention time. We keep the angle of inclination of Tubes between 45 degree and 60 degree. since above 60 degree angle will cause them to be ineffective and below 45 degree angle will cause choking problems.

The equations for settling is simply derived from time- distance-speed relationship, which further calculates the distance required to settle the particle with and above a specific settling velocity.

Since the water is supplied through small channels the fluid attains least turbulence and thus keeps the control over flow pattern.

- Gurgaon, Haryana, India

June 30, 2010

A. The advantages of tube settlers over plate settlers are numerous. 1. Tube settlers are self supporting block, plates need specific grooves with fixing mechanism. 2. Tube settler can be easily fitted into a circular/square/rectangular tank, plates are suitable for rectangular/square tank only. 3. Tube settler made of UV stabilised PVC are more economical than plates. 4. mechanical strength of TS block is more than plates. 5. TS block allows foot traffic. 6. Choking chances are less as compared to plates. 7. Efficiency is more than plates. 8. Provides higher settling area compared to plates.

Santanu Paul- Delhi, India

September 1, 2010

![]() Hi, cousin Santanu.

Hi, cousin Santanu.

If you present 8 advantages for tube modules and no advantages for its very widely implemented competition, people might dismiss your posting as product advocacy rather than a balanced technical presentation. Please consider the time-proven approach of "damning your competition through faint praise" :-)

Luck and Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

September 2, 2010

A. Hi Ted,

Sorry if you found my views appeared as a one-sided affair. Here are 8 advantages of plate settler. 1. Plates made of SS have longer life. 2. Plates can be removed from the slots for cleaning and packing them back into grooves. 3. Plates can be ordered as per design and delivered by the manufacturing company for ready to fit in. 4. Needs less storage space at site during installation. 5. FRP plates are easily available in the market. 6. FRP plates are comparable in price against Tube settler made of UPVC. 7. FRP plates have higher thickness than Tube settler. 8. FRP plates can be easily resized at site during installation.

Hope this satisfies .. :-) and helps the reader to take judicious decision ...

- Delhi, India

September 3, 2010

September 3, 2010

![]() Thanks, Santanu! Now, thanks to your extreme diligence, this page represents a thoughtful, balanced and very good answer to the question!

Thanks, Santanu! Now, thanks to your extreme diligence, this page represents a thoughtful, balanced and very good answer to the question!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I would like to ask the effect of hydraulic radius on the settling phenomenon in tube settler / lamella plates?

What happens when we increase the hydraulic radius?

- Gurgaon, Haryana, India

September 1, 2010

A. Hi, Sourabh

Increasing the hydraulic radius means making the tubes larger in cross sectional area. From a practical standpoint this may make the tubes less subject to becoming blocked, and easier to clean out. The disadvantage is that a particle has further to fall before contacting the bottom of the tube, so the workable flow rate for the clarifier is theoretically reduced.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

September 3, 2010

Q. Dear Ted,

1. At the onset I would like to thank you for your reply. If you can give a mathematical relation that would be beneficial.

I would also like to ask if Reynolds number has something to bear with? if yes, your explanation will be thankful.

2. Regarding Shantanu, Paul I would also like to thank him for stating the advantages of tube settlers. But Ted I would also point out that you made us picture a two square foot tube settler, which was never required for such a small size and moreover the loss of area you pointed out shall be both in lamella plates and tube settlers provided they are inclined.

I would also like to have some major advantages of lamella clarifier.

Thanking you

- Gurgaon, Haryana, India

September 3, 2010

A. Hi, Sourabh.

1. This website receives close to 200 inquiries a day, allowing me only 3 or 4 minutes to dispatch each inquiry. So I apologize that generally, when a question requires research or investigation into mathematical models like Reynolds number, etc., I have to rely on readers who may specialize in that field to answer it. Sorry.

2. The blocked area of tube-module clarifiers that I described is because tube modules are usually placed into round or rectangular tanks. There is always some blocked area, and it is almost insignificant in very large tanks but becomes ever more significant as ever smaller tanks are used. All of the lamella plate clarifiers that I have ever seen involve tanks with sloped sides rather than vertical sides (the tanks are the shape of a single tube of a tube module); they are more involved to build, but there is no blocked area.

A reply from Shantanu, offering the advantages of lamella plate settlers crossed in the mail and is printed above; I think it will satisfy your needs in that regard. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

September 3, 2010

Q. Dear Ted,

I appreciate your view point, but the same vertical walls can be with tube-settlers too. A query comes into my mind, does the shape of tube settler effect the settling phenomenon? I have seen tube settlers in hexagonal, circular, hexagonal chevron etc.. does it really effect on area / m3 ? I would be thankful to you if you could bestow your knowledge on the subject.

Thanks to Santanu Paul for letting us know the advantages of lamella plates.

Regards

- Gurgaon, Haryana, India

September 4, 2010

Q. Dear Ted

The advantages given by Shantanu for plate/tube settler are on their physical characteristics but query is remaining. Please give comparison on functional characteristics. which is better for same tank size & for the same flow.

thanking you

- Mumbai, India

June 16, 2011

June 16, 2011

A. Hi, Prakashchandra.

My personal opinion is that the substantive difference is the physical shape rather than any functional characteristics :-)

They are used for the same purpose, both are widely and successfully employed. The lamella plate design, by having a longer fluid path for the same particle drop path, allows the same flow rate in a taller but smaller footprint. The tube settler is not tall and unwieldy. In brief, although there may be some differences in the fluid dynamics aspects, and I don't strongly disagree with the advantages/disadvantages previously presented, for me the physical shape of the tank is the most defining difference, and has usually been the chief selection criteria in the projects I've worked with. Just my opinion.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear Ted,

We have Circular (Concrete) Clarifiers designed for gravity settling. Can we install plate / tube settlers in these clarifiers to increase capacity/flow rate without compromise to quality of treatment ?

Thanks in advance for your response.

- Bangalore, Karnataka, India

March 21, 2012

A. Hi, Shiv.

Probably! You do need to make sure that the weirs are such that they will work properly at the higher flow rates; you need to be aware that higher flows means more turbulence; you need to make sure that the higher solids loading that will result from higher flow rate won't be a problem. i.e., that there is some room for sludge accumulation.

But, yes, that's the idea behind tube settlers; and yes, back in the distant past, I remember being involved in a project that did just exactly that.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 21, 2012

Q. Has anyone come across any software tools to assist with the design of inclined plates

Peter Anthony- Durban, Kwazulu Natal, South Africa

January 28, 2013

Q. My lamella plate clarifier has sludge obstruction! Why? Thanks for help.

dada kaboji- afghanistan kabol

June 5, 2013

A. Hi cousin Dada. It's difficult to answer because the readers do not know the operational conditions, but it is possible that you had a very heavy sludge loading and did not remove the bottom sludge fast enough. Try to get the sludge pumped out if that is applicable. It is also possible to overdose the polyelectrolytes and thereby give the sludge too much "body", making it sticky and robust enough to block the tubes. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 2013

A. Having worked with Tubesettler technology for more than 50 months, have found that tube settlers are best performing when the solids loading are less (as in case of municipal wastewaters of industries with low sludge post treatments (less inert TSS in inlet and less yield). These have a hydraulic radius of 80 mm or even 60 mm for hexagonal chevron model which keeps the velocity of settling low through pipes and thus the Reynold's number.

When we are to handle large quantity of sludges we work with lamella plates spaces about 100 mm apart (spacing can even be different based on requirements and quantity of sludges generated).

There are no specific tools available, yet the calculations for finding tubesettler media and tank size are simple.

Having a tubesettler or lamella after an activated sludge system (suspended growth system) is not recommended, as the sludges have affinity to stick on the surface of the plates/tubes.

The energy and resources institute - delhi, India

May 15, 2015

August 2016

![]() Thanks, Sourabh.

Thanks, Sourabh.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear Ted,

You said, that the main difference between tube settlers and lamella clarifier is the physical shape but could you explain the hydraulic difference? Are there any influences caused by the borders of the tubes? Maybe there are any possibilities to convert some parameters like velocity or particle settling from lamella clarifier to tube settlers (or the other way around)?

And how can I calculate the effective settling area for tube settlers? For lamella clarifier it's the horizontally projected area but can I use this for tube settlers, too?

Thanks for help.

- Karlsruhe, Baden-Wuerttemberg, Germany

August 2, 2016

August 2016

A. Hi Achim. I tried to explain 10 years ago that from my perspective as an engineer packaging these units together as part of wastewater treatment systems, the most salient selection issue was usually just the shape of the tank: the lamella systems being rectangular and tall (sometimes a problem), but small in footprint; the tube settler style usually being round, short and squat, and consuming more real estate (sometimes a problem).

Each successfully served their function for me; each had periodic issues like blocked channels, sticky sludge, flotsam, insufficient sludge capacity, difficulty in determining sludge level, etc. It's not an opinion that I can put a superfine point on. They both worked, they both had similar periodic misfires.

Although others on this thread, such as Sourabh, seem to have suggested that they have done hydraulic analysis on tube settlers, and that the sides of the tubes affect such calculations, I haven't. Sorry; for me personally, such calculations would represent precision without accuracy.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

|

|

Q. Would any of you friendly people know where I can find some good settlers out here in the Orange County area? Roger LeonEnvironmental Compliance & Safety - Santa Ana California December 7, 2016 December 2016 Hi Roger. Sorry, but allowing testimonials to brands or sellers on this site has proven to be a disaster time & again (why?). It opens the door to boundless spam, acrimony, insults, sales people posing as satisfied customers, etc. Apologies, but we must leave sourcing to the search engines. Experience has proven that testimonials and vendor suggestions just does not work here; plus we are trying to be a permanent technical reference, and offering suppliers/distributors names on our 27 year old (and counting) site in these changing times tends to litter it with broken links:-( Good luck, and Regards,  Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. |

February 21, 2018

ACRONYMS:

HRSCC = High Rate Solids Contact Clarifier

Q. I would like to know the Cost difference between Tube Settler & HRSCC. Which would be more cheaper and why?

NINAD MARATHELARSEN & TOUBRO - VADODARA,GUJARAT, India

A. Hi Ninad. There is no question about the benefit of solids contact. Occasionally, conventional tube settlers and lamella settlers have the incoming wastewater enter below the sludge level; and recirculating a slipstream of sludge into the incoming wastewater is a common design feature. But I am personally unfamiliar with HRSCC; so I can't comment on its use in place of tube settling. As for cost differences, please simply get quotes for the correct capacity units ... it's possible that for smaller sizes one technology is cheaper and for larger sizes the other. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2018

Q. I want to calculate sedimentation area of tube settlers. Please help me or send me some documents for answer. Thanks.

VU THUONGSetfil - Ha Noi, Viet Nam

April 24, 2018

Q. Hello, I am an engineering student and I've been looking for the design parameters for a tube settler from the criteria that must have been met like the Reynolds number and such to the settling velocity of the particle, but I only see examples from plate settlers not tube settlers, I would like to know if any of you could provide me the formulas or an example to be able to understand it, because I saw a model and not all the tubes have the same length they go from longest to shortest as they get near the exit. I have done a lot of research with my available resources with no avail, thanks :)

Noel RodriguezUniversidad tecnologica de Panama - Panama

July 16, 2018

July 2018

A. Hi Noel. I was introduced to Reynolds Number in my Fluid Dynamics course, but I'm out of school 50 years now and was never once was in a discipline which used Reynolds number calculations, so I'm too lazy to re-learn them now, sorry :-)

But in the tube settlers which I have seen, there were no "longest and shortest" tubes, there were only the long, functioning, tubes and the short blocked tubes (the flow blocked by the walls of the tank). Best of luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I am interested in inclined plate lamella clarifier design for storm water treatment. I need a discharge of 10 liters per second. The TSS is basically silt, ranging up to a max of 800 ppm. Please advise.

Samanpreet baweja- Ludhiana India

July 31, 2019

Q. How can we calculate rising velocity in tube settler clarifier, if the flow rate is 125 cu.mtr/hr. and inlet pipe size is 6" id. and outlet is 8"id

mani kumarvk enterprises - Mohali, Punjab , India

August 13, 2019

A. Hi Mani. To my knowledge the inlet and outlet IDs have no effect on the rise rate calculation. Rather, I think you divide your 125 cubic meter / hour flow rate by the surface area of the clarifier in square meters and you have your rise rate in meters per hour. If the surface area of your clarifier is 125 square meters, the rise velocity is 1 meter per hour. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August 2019

A. There are some good video tutorials for this topic online. One example that explains the differences between a tube and plate settler is here: https://youtu.be/z_N0e3UzVb4

Dennis Fisher- Huntsville, Texas

January 1, 2022

Q, A, or Comment on THIS thread -or- Start a NEW Thread