-----

Copper Whiskers during Copper Electroplating

Q. We are seeing copper-Whisker formation during copper electroplating process. These whiskers initially grow very rapidly may be during first half an hour. We add about 35 per million parts of chlorine in the copper plating bath. has any one experienced these copper whiskers in their plating operations? If so how do you get rid of them?

Rathindra Pal- Silver Spring, Maryland

1999

A. We see a treeing effect while acid copper plating. It's like the tin/lead "whiskering" phenomenon. We run a brightened bath and find that the brightener/carrier help cut down on the treeing. Also, about 50 ppm chloride is recommended so your bath may need a little more. You're using phosphorized anodes, right? Does the whiskering occur more in the HCD areas? If so, you might want to check your anode placement and racking configuration.

Megan Pellenz

- Syracuse, New York

1999

Q. Has anyone seen a correlation to the surface topography? we see whisker formation on rigid panels that have RTF foil but don't see them on flex panels that use RA foil.

Mark Kinder- Milpitas, California, USA

September 23, 2010

Copper whisker challenge

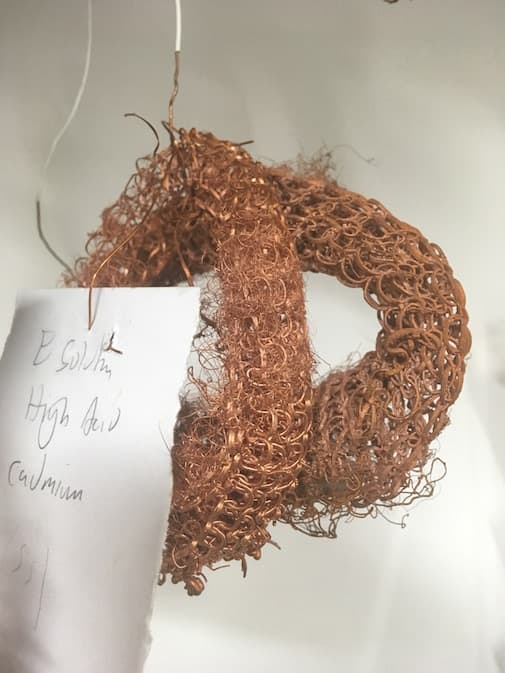

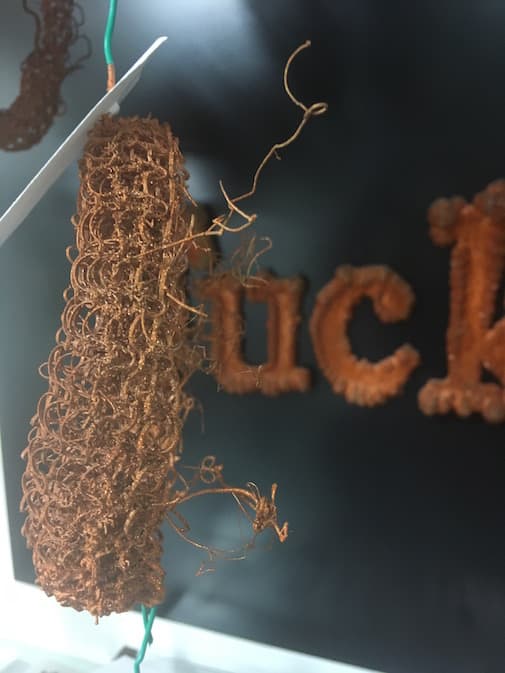

September 21, 2019Q. Hi There- I'd love to follow up on this copper whisker issue. I should introduce myself however as an working artist and sculptor who uses electroplating and forming in my work. I've spent the last two years actively trying to find and encourage unique formations through plating, and in that process stumbled upon a way to force copper to grow whiskers. Perhaps it may be of use to you.

I want to be clear these are NOT nodules, the formation of those is quite straight forward and I'm sure you are familiar with them. The whiskers defy explanation and clearly grown in a way that is contrary to the nodules in that they don't seem to result from the feedback loop of high current density areas but rather seemingly from an end point process- like hair growing from the tip.

When I can get them to form they form spontaneously and often quite quickly. However I am also not a chemist or a scientist, and I'd like to improve my methodology but I'm really just guessing. If anyone has more information on this, not how to stop it but rather encourage it I'd like to know more. In fact I'd be thrilled if someone took on the challenge and tried to re-create what I've done in my studio. It's harder than it looks but maybe that is a fun project for a willing mind. If so I'd love to share notes

Raphael LyonArtist - Brooklyn New York USA

September 2019

by William Safranek

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Raphael. The only comments I can contribute are that "whiskers" are very well known on tin plated objects (and some others), are believed to be a stress-reduction phenomenon, will occur in the air over time, and are reduced by lower stress deposits and plating alloys rather than pure metals.

So I would suppose that accelerating them would involve plating very pure copper deposits under conditions that cause tensile stress (high current density, low temperature, and maybe excessive chloride in the bath?) or you might try molasses as an addition agent to shoot for compressive stress and see if that promotes them or not.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi Ted- Yes there is a lot of information on Tin whiskers -- but they seem to be spontaneously developed, and not a function of electroplating. (I've found materials showing old tin pins that held beetles in museum displays growing them!) There seems to very little information about copper whiskers -- even less about them in electrolytic solution.

You are correct in that high current density, low temperature seem to be factors -- it was certainly easier to get this done in the winter- the whiskers would tend to form on the edges of maximum current density, just short of burning, increasing the sulfuric acid -- to the point of saturation seemed to help.

I'm interested in what you were getting at with the molasses . My understanding is that molasses acts to limit high density points and encourage brighter finishes. How would that encourage the whisker growth.

Or am I wrong here? Is that what you mean by "competitivecompressive stress"?

artist - Brooklyn, New York, United States

September 23, 2019

A. Hi Raphael. Safranek seems to say that molasses can be used to cause compressive stress in the deposit. Whether stress in that direction and of such limited magnitude can assist in development of whiskers, I unfortunately have no idea :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

September 2019

Ed. note: Readers may find these related threads interesting:

Topic 0085, "Copper electroforming problems" and

Topic 12635, "Needle like growth in copper acid electroforming bath"

Q, A, or Comment on THIS thread -or- Start a NEW Thread