-----

TECHNICAL INFORMATION ABOUT BLACKENING FOR STEEL AND CAST IRON

HELLO FELLOWS I AM LOOKING FOR INFO ABOUT HOT AND ROOM TEMPERATURE BLACKENING FOR STEEL AND CAST IRON PROCESSES. I WOULD APPRECIATE TO RECEIVE TECHNICAL INFORMATION ABOUT THESE PROCESSES. IS THERE ANYONE THAT COULD SEND ME SOME LITERATURE ABOUT DETAILS AND COMPARATIVE TRIALS ? MANY THANKS IN ADVANCE.

RICARDO BASTOS- SAO PAULO- BRAZIL

1999

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Sir, Blackening salts consist generally of alkaline OXIDIZING SALTS and are readily available with the chemical mfrs.The most imp.thing about the process is to have a working temp. of 135 °C to 145 °C. If it is less than or more than this range, the color will not be black. The TIME OF TREATMENT is generally 10 TO 15 MINS.thanks, Ramajayam

S,RAMAJAYAM- Bangalore, KARNATAKA, India

1999

Hi, Ricardo. We have an FAQ on black oxide vs. cold blackening., which may serve as an intro. Further info can be found in the Metal Finishing Guidebook or from the suppliers of cold blackening processes.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

I have done both. Room temp. is less expensive and a lot safer, but it is a "poor mans" black oxide. It has its place and is fully functional for many uses, but it does not offer the beauty or corrosion resistance that a hot one does.

James Watts- Navarre, Florida

1999

1999

Try this for a jet black finish on steel parts:

1) coat the part with heavy motor oil

2) heat the part (oven, furnace, etc)to 350 °F; the oil will bake into the part surface in approximately 10~15 minutes

3) this finishing is quite durable. Of course, there are other processes for bluing steel parts (heat, cold, etc.) that can produce a very dark blue color that maybe can turn out satisfactory to your purposes. Good luck

- Brasilia, Brazil

I AM LOOKING FOR INFORMATION REGARDING THE COLD BLACKENING PROCESS AS A VISUAL ART FINISH FOR LARGE COLD ROLLED SHEET.

WE HAVE BEEN USING DIP TANKS TO ACHIEVE AN INDUSTRIAL FINISH THAT HAS PROVEN TO BE VERY POPULAR, HOWEVER IT HAS BEN HIT AND MISS AS FAR AS THE CONSISTENCY OF THE PROCESS AND ITS OUTCOME. our LARGEST PROBLEM IS RUST APPEARING 2-3 WEEKS AFTER INSTALLATION ... ANY IDEAS? I sincerely appreciate any effort at my expense. Thanks.

Jeffrey McPhee- Seattle Washington, USA

2000

2007

I HAVE GOT THIS FROM NET. HOPE THIS WILL BE USEFUL FOR YOU.

OPERATING INSTRUCTIONS FOR DU-LITE'S STEELKOTE BLACK OXIDE SALTS FOR BLACKENING OF COLD ROLLED STEEL, PLAIN CARBON AND LOW ALLOY STEELS:

du-lite.com/instructions/pdf/OI-STEELKOTE.pdf

Deepan senthil kumar.R.- Covai , Tamil Nadu , India

adv.

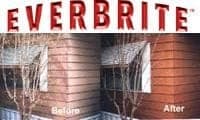

If you are having problems with rusting after you patina, you can apply Everbrite coating (most prefer the satin finish) and it will stop the rust AND oxidation.

Everbrite Coatings

Rancho Cordova, California

January 27, 2017

Q, A, or Comment on THIS thread -or- Start a NEW Thread