-----

Chromic Acid Anodizing: Introduction and Problems & Solutions

finishing.com is made possible by ...

for Chromic Acid Anodizing [Detroit, MI]

"Salt fog" or "salt spray" is shorthand for corrosion resistance testing, which is usually done in accordance with ASTM B117 or ISO 9227.

Q. Hello,

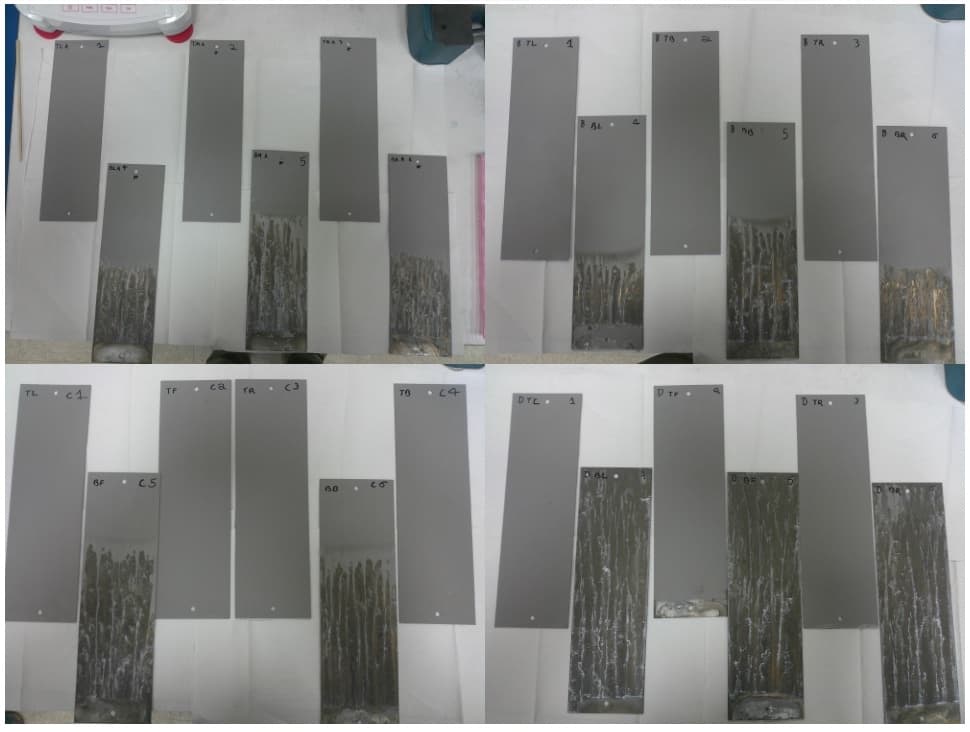

Several months ago we began to experience chromic anodize corrosion panel failures after salt fog, since then we have run many sets of 2024 panels (6061 pass with no issues). We have found a pattern showing that only panels on the bottom of the rack fail and with a hard separation between corroded and non-corroded areas usually about half way up the panel.

The bath has been fully remade since this was first observed and no change was made. What could be causing this very specific failure? Has anyone seen this before? Thank You.

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Krepela

- Black Mountain, North Carolina

February 11, 2025

⇩ Related postings, oldest first ⇩

Aluminum How-To

"Chromating - Anodizing - Hardcoating"

by Robert Probert

Also available in Spanish

You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

Q. Hello all,

I've been Anodizing for about a year and a half. So you can say that I am still very green! I have been very impressed with the answers given to a lot of questions here at this great site. So now it is my turn to ask one ...

We have parts that are being Chromic Acid Anodized, then sealed with a Dilute Chrome Seal. The parts are coming out powdery.

What do you think it is?

A quick response would be very appreciated.

Randy Mattson- Seattle, Washington, U.S.A.

2001

|

|

A. Assuming you're anodizing it right, then that powdery stuff ('bohmite?') indicates that your parts are completely sealed. Dado Macapagal- Toronto, Ont A. Could be a couple of things. 1 The seal - check the conductivity etc - better still just dump it to remove from the trouble shooting loop. 2 Temperature. If the parts are producing a white powder that comes back when you wipe it off, (normally the time taken to go from your place to the customer) temperature is the problem. It is the solution getting too hot and driving the film dissolution reaction faster. This results in bigger pore size in the anodic film and the pores are too big for the seal to fill. The answer is to run the parts a little cooler, try different settings but only change by 2 C at a time, it will only take a small change. The other thing may be the shape of the part causing solution to be held in an area where it then over heats, we had in side a part the size and shape of a top hat. A jigging change and higher solution agitation solved this.  Martin Trigg-Hogarth surface treatment shop - Stroud, Glos, England |

by Runge & Kaufman

on eBay or Amazon

or AbeBooks

(affil link)

Q. To: All

Presently we are awaiting our customer's approval on our chromic acid anodizing process. As we are waiting, I come to think of possible problems which are usually faced by the processors. What I am referring to are the problems that we could not get away with; kind of a consequence of the process. If that is so, I wanted to be prepared. If the problem is surely expected after a time of processing, then there should be solution already at hand. And what are those expected problems to be dealt with?

I'll appreciate any input.

Thanks,

Nila O. Par- Winnipeg, Manitoba, Canada

2003

A. Almost all problems with chromic acid anodize are self induced. Parts not clean, inadequate clip (clamp) contact, tank analysis not done often enough, too big a load for the heater to maintain temperature, times not adhered to, bad rinsing and abuse of the parts. If you follow your established procedures, you should have zero problems.

James Watts- Navarre, Florida

Q. Dear Mr. James Watts, Thank you very much for responding quickly. I am lost when you say bad rinsing and abuse of parts. Will you please expound on these? Thanks again.

Nila O. Par [returning]- Winnipeg, Manitoba, Canada

A. Bad rinsing- not getting all of a process chemical off the parts and rack before going into the next chemical. This causes as many problems as anything else in anodizing because operators get in a rush and owners rarely have adequate number of rinse tanks, which leads to high waste treatment costs or rinse tanks becoming "foul". It also forms salts on the surface from the chemical reaction of the different chemicals. A single rinse is adequate between the anodizing tank and the seal tank, but not on any of the others!

Abuse- sloppy racking and de-racking, banging loaded racks against other racks or objects, throwing parts into a tote bin and . . .

A note of warning that I forgot. When you make up a new anodizing tank, leave about 5% of the old tank or run a couple of dummy loads to get some aluminum into the tank. If you do not, the first load of parts will be a nice bright olive green color instead of the color that you will get on later runs. This is extremely hard to explain to a customer. This strong visual difference will be picked up by the worst sloppy QC incoming inspector.

James Watts- Navarre, Florida

Chromic anodizing contamination

Q. We received some parts from an anodizing company that have visible "speckles" on the surface after chromic acid anodizing.

The material was 0.125" thick 7075-T6 Alclad which had been machined at the ends.

The "speckles" were not visible on the machined ends (ie: area where Alclad had been removed).

The material was not visibly contaminated or damaged in any way when it left here for anodizing.

What could likely cause this ?

Could it be material type/surface finish ?

Or could it be process related (something our anodizing supplier did)?

And what steps can we take in the future to prevent an occurance ?

aerospace - Winnipeg, MB, Canada

2005

A. If you used 40 volts on the 7075 maybe you are pulling out too much zinc; try the 20 volt process.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Hello, I work at a anodize job shop in the Detroit area. We strictly do sulfuric anodizing only but are getting ready to start up a small chromic acid anodizing operation in June. I do the titrations and was wondering why it's important to know the free Cr04 anion instead of the free hydrogen ion when checking acid levels in TYPE I. The hydrogen cation is what gives the aluminum oxide the porous structure through dissolution of the coating in TYPE I,II and III anodizing, doesn't it? Or maybe I misread past postings on the TYPE I titration.

Thanks,

Plating shop employee - MADISON HEIGHTS, Michigan, USA

April 2, 2008

A. An old copy of Metal Finishing Guidebook lists testing for free chromic with a calibrated pH meter to a pH of 3.05. This takes a good electrode and good care of it to have any accuracy and length of service. CrO3 is titrated with an starch/iodine endpoint.

Back in the dark ages, I had an OEM spec that told me what I had to do and how to do it.

The 20 volt method works quite well on 2014 aluminum. Till you build up aluminum in the tank, your parts will come out green instead of gray.

- Navarre, Florida

Q. Mr. James Watts, you mentioned that chromic acid anodizing will form salts on the surface from the chemical reaction of the different chemicals.

Can you name these chemicals?

- Penang, Malaysia

September 14, 2009

A. Hi, Damian. I think what Mr. Watts said was that if you follow the procedures you will have no problems, but inadequate rinsing will form salts on the surface. Those salts would be whatever the parts had been dipped into. In the case of the chromic acid tank itself, it would be chromic acid plus whatever else is in the anodizing solution.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Where does the chrome go? Okay, I've been in sales too long. I understand the chemical concepts behind electroplating well enough, but evidently not well enough because switching the problem around, i.e., with anodizing (let's say in a chromic acid solution), I lose it. Besides chromium emissions due to mist (and some due to tank cleaning I'd think, but at low levels with proper precautions), is there an actual oxidation-reduction reaction occurring, and is the Cr+6 reduced to +3 chromium that subsequently bonds to the tank shields and is removed as a shiny solid for clean up? In other words, in a chromic acid batch, where does the chromium element go after the oxygen is provided to the aluminum anode?

Thanks,

Brad CarpenterEnvironmental Management Software - Maple Grove, Minnesota, USA

2003

A. By far the biggest loss of chromium is drag out by the racks and parts. Chrome 3 in the solution should be converted to chrome 6 by the high voltage used.

James Watts- Navarre, Florida

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Brad. Yes, in a way anodizing is the opposite of plating because the polarity is reversed. But it is not electroplating in the opposite direction (onto the anode). Rather the anodization is a compound of aluminum from the substrate and oxygen from the water in solution. There is no chrome plating involved except incidentally; the chromic acid is simply the electrolyte that the oxidation process takes place in. As Jim says, dragout is the major way chrome leaves the tank.

For more on this topic, you might want to take a look at "The Surface Treatment and Finishing of Aluminum and its Alloys".

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. We have just chromic anodised some alloy bodies with lots of blind holes in them. After anodising 40 of them and washing them all off in water, we took each one of the jigs and washed all holes out ... when I noticed 12 out of 40 had a small hole right the way through them. There was a lot of black dust in the blind hole which was not there when we started the job. The solution is checked every month. I have never had a problem with chromic anodising before. I always felt chromic acid would find out if there was a defect in the alloy -- it would show up in some way. Has anyone else had a problem, as now I have to tell my customer something?

Martin Jackson- Hounslow, Middlesex, UK

November 11, 2012

A. Obviously the holes have organic or inorganic soil inside. This could be cutting oil, or aluminum bits from the drilling, and/or work hardening from a dull drill. Next time through, go up/down/up/down/up/down, completely in and out of solution in the cleaner, deox, and all rinses.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Hello,

We are having difficulty with our Chromic Anodizing tank. It was recently made up new, and our operators are having issues with visual appearances particularly with 2024 alloy. Coating weights tests have been done and they are will within the spec limits. Currently, our total chrome is ~56 g/l and the free chrome is 50 g/l. Thoughts?

- Dayton, Ohio, USA

April 19, 2013

|

A. First, exactly what is the visual problem? - Navarre, Florida A. Hi Trent, Aerospace - Yeovil, Somerset, UK |

Q. The particular visual appearance problem is one that some of the part has a dark gray look across it, while other areas of the part has a lighter gray. Also, it looks like a streak appearance that runs horizontal across test panels, not in a particular area, but across the whole panel. We run at 40 volts, and our sealing times vary from 20-40 minutes. Is it that the total chrome concentration is low enough to cause these problems? It just seems like whenever we make up a new Chromic bath, we have some type of visual issue. Would it behoove of us to change parameters to allow for a higher total & free chrome makeup?

Trent Elam [returning]- Dayton, Ohio, USA

A. What kind of seal? If a hot water seal, then Alcoa said in 1956 and AES repeated in their earlier slide show, that a hot water seal for over 10 minutes does degrade the coating. Granted, the MIL spec calls for 15 minutes and I cannot get them to consider changing it, but I have proven that hot water over 10 minutes degrades the coating. The other important thing is the anode/cathode ratio which must be about 5/1 to 10/1.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. I am looking for information on rinse tanks, particularly our anodize rinse tank. We just recently have encountered some 'mysterious' staining on our anodized parts that we have never suffered from before. We have looked at many of the common variables and nothing seems out of the ordinary. We want to examine our rinse tank a little closer than just checking the pH and Dissolved Solids. I did do Cr+6 analysis on a sample of our rinse but have nothing to compare it to. Could someone please give me an idea of what amounts could be expected in our anodize rinse tank due to drag out, etc. Thanks for ANY help at all!

Jillian Penny- Amherst Nova Scotia, Canada

October 29, 2014

Chromic Anodizing Electrical Breakdown Problem

Q. I am doing a Chromic Anodize process on 2014 T4 Alloy which has to withstand an electrical breakdown current of 50V DC.

The anodize Process:

Every 2 Minute the the voltage is ramped up by 5V up to 40 V. and at 40V it is kept at 35 - 40 mins.

Before anodizing the material is washed in Nitric Acid (50% Nitric Acid and 50% Water) ,

Post Anodizing the material is sealed in Hot water. Sometimes there is no electrical breakdown until 5000 Nos and then the breakdown starts again. I have to then throw the whole bath and make a new one. Is there any other way where I do not have to throw away the water?

Anodizing Shop Owner - Kolkata, India

October 19, 2015

Acid attack/ pitting

Q. We plate a part that is chromic anodised apart from where hard anodising is required. This is where I have the problem. The hard anodising is okay; it's always the side face were it looks like acid attack and pitting.

We wax up as follows: first, we use the side face to jig onto which is a threaded bore with a threaded bar which is hook shaped. We wax first for 30 minutes, then cool, re-wax, cool, then fill any holes, re-wax, cool, remove the jigging bar, clean the area to be hard anodised, then refit straight threaded bar for plating. Before this, seal around the part where you have screwed the new jig in. After plating, strip in hot water tanks. This is when we notice that where the jigging bar has been there is acid attack / pitting.

We do these parts in loads of 4; not all parts come out like this. Plating is done at 6.00 Amps, temperature 00.00 to 00.05 °C for sixty minutes. We have tried stop-off lacquers, but no good. Thanks.

andrew thomasplater - uk

December 10, 2015

A. Good day Andrew.

That is quite an interesting problem. You process four pieces at a time, and state not all pieces show the pitting.

Where on the flight bar are the defects? Is it at the ends, as HCD?

How large are the pieces and what is your voltage/ASF?

What is the sulfuric concentration?

What I am getting at is, do you have enough electrical contact area to carry the current?

You state that you remove the jigging, and install a threaded bar and seal before anodize. Are you sealing with the same wax?

I am thinking this sealing is compromised, and my question to you was do you have enough contact area, and how many? Maybe it is a "burn"issue.

I am thinking this is a situation where possibly heat is being generated, allowing anodize solution to "seep" into this area.

Food for thought.

Hope this helps.

Regards,

Aerotek Mfg. Ltd. - Whitby, Ontario, Canada

Arcing around plugged holes during chromic acid anodize

Q. The anodize operator in our shop is having an issue with arcing / etching around the top edge of threaded holes during the chromic anodize process. The holes were being plugged with green neoprene plugs. We switched to a softer silicone plug and the problem still persists.

My question is, Are the plugs causing this problem at all? Or could something else during the process be the cause?

Jeremy Wrightshop employee (masking) - Salt Lake City, Utah, United States

December 2, 2016

A. I'm not an expert in Chromic acid anodizing, but I've never heard or seen a plug causing this issue in sulfuric acid anodizing. Is it all of the threaded holes on the part? Is it the same hole every time? Are the same plugs being used on other non threaded holes in the part? Something weird is definitely going on here, I do not think it's related to the plug.

Marc Green

anodizer - Boise, Idaho

Q. Those are the only holes masked by plug on the part. It's not always the same hole that has issues.

Jeremy Wright [returning]shop employee (masking) - Salt Lake City, Utah, United States

A. Until you give us some more data, here is a very wild guess.I suspect the plugs are leaking, filing up with deoxidizer, then where the deox leaks out, since it is more conductive than the anodizing solution, it attracts high current which burns away the edge of aluminum.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Brown stains on chromic acid anodising

Q. Hi Ted and the community,

Here at our facility we chromic acid anodise parts made of AMS 4050 T7451.

It's a standard ramped process, preceded with aqueous degreasing, alkali etch, and de-smut. The parts are showing brown stains over most of the parts, but especially in recessed areas.

Other parts from other alloys anodise as normal in the same bath, with no signs of stain, it only happens on this one alloy.

One possibility that has been suggested, is that the areas showing the stain may have been stressed during their machining, or via over zealous hand linishing.

If anyone recognises this situation, then I would be glad to hear your remedy to it.

if you need any more information in order to better answer this request, then I can supply it.

Thanks and best regards

Mark

Industrial Chemist - Windy rock in the middle of the Irish Sea

October 3, 2017

A. Hi,

This is called Machine abuse or localized heating during machining, exhibited after anodising.

This can be corrected in machining with Feed, speed and coolant circulations.

All the best

- Belgaum, Karnataka, India

![]() Thanks Shankaranrayanan,

Thanks Shankaranrayanan,

we had our suspicions that some sort of machining damage was at the root of this.

Thanks for your corroboration.

Best regards

Mark

- A not so warm rock in the irish sea

Increasing aluminum in chromic acid anodizing bath

Q. Hi to everybody, we have a new bath of chromic acid anodizing and we need to "age" it before starting the process. Usually for doing it we treat some scrapped aluminum sheets until we reach the minimum Al content of 1.5 g/l. This process is quite long. Is there another solution for aging the bath?

What happens if we use an anodizing bath with too low Al content in it?

Thanks in advance for your help. Have a nice day.

- Sesto Calende (VA), Italy

April 4, 2019

Q. Hi, it's possible the chromic anodize application could "eat" the material (al alloy) and reduce the part dimensions, is it? Why?. We had this problem.

Thanks.

Landing Gears overhaul - Sunrise, Florida USA

October 5, 2019

A. 1. Some imported chromic acid is high in sulphates.

2. Look for chlorides in your water, especially in Florida.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Hello. We are performing type 1 Anodize on aluminum material. When we run production we use an uncoated titanium rack. Upon ramp up the amperage does climb a bit while we try to achieve 40 volts. At times on the ramp up and when we reach 40 volts both the amperage and voltage meters will fluctuate quite a bit. Also when we run monthly test panels 2024 aluminum we use a coated titanium rack. The thing is when re-run our panels our amperage barely rises to about 9 amps. Any thoughts

Steven Sanchez- Laveen, Arizona

April 9, 2021

A. Hi Steven. I don't know enough about the spec requirement to say, but I think you need to run your test panels the same as your parts -- so uncoated racks for production parts and coated racks for panels might be an issue.

In my limited experience when the amperage momentarily jumps in anodizing it is because a part that was not making proper contact suddenly starts to at a breakthrough voltage.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. 1. What Ted says above, then

2. Is the air agitation hitting the parts and randomly displacing solution.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

A. If you are doing Type I chromic acid anodizing it is most likely Aerospace. If it is Aerospace then you must be NADCAP approved! Nadcap REQUIRES that test panels are run with and the same as production work. This is just a guess but I would call in a rectifier supplier and have the DC power supply checked out and certified

Drew Nosti, CEF

Anodize USA

Ladson, South Carolina

Q. I have done chromic anodizing on aluminium material 2014 T6 grade but after anodizing I found that part came with a shade like some patches. I unable to resolve this problem

My bath concentration

Density is 1.06

Voltage 50 volts

temp 26 °C

Kindly suggest

- Nagpur India

December 14, 2021

A. Hello Anmol.

It might be easier to help determine the cause of the problem if you could show pictures. My initial thought is if the cleaner did an adequate job in removing any grease and or oils.

Thank you.

supervisor - Cicero, Illinois

Saporito Finishing Co.

Q. Currently we are facing problems in the chromic acid anodizing process, when the CAA process was carried out on Al 2024 T3br material, (with 20 Volts, processing time 50 minutes, sealing dilute chromate temperature 92 °C, time 25 minutes), there were several problems:

1. there is a powder in the formed layer

2. After 336 hours of corrosion testing, there was "discoloration" and a lot of corrosion pitting.

What factors are the cause and what solutions should be implemented?

I would really appreciate all the feedback that comes in, thank you.

employee (manufacturing process development) - Bandung, west java

March 24, 2022

A. This may help:

Obtain 22 ±2 volts DC (Optional: 40 ±2 volts) starting at a setting not greater than 5 volts and a rate not to exceed 7 volts/minute.

Anodizing at 22 volts is required for 2090, 2019, 2091, 2219 and 7178 alloys, for 7075 alloy in the - T73 condition, and for Class 4 sealed parts.

Achieve 22 ±volts or 40 ±volts within 7 minutes after application of voltage.

Drew Nosti, CEF

Anodize USA

Ladson, South Carolina

Q. I'm trying to anodize AA 2219 T85 with chromic acid (Temp. 38-40 °C) at 50V for 40 minutes.

After sealing at 97 °C for 40 minutes, parts are turning to dark colour.

We use sodium hydroxide (8% w/v) at 60 °C for de-scaling and Nitric acid (50% v/v)- room temperature for de-smutting.

Duration is 2-3 minutes for De-scaling & De-smutting.

We use DM water for all processing tanks (tank capacity: 5000 liters each bath).

Anodising process parameters: 0-40V in 10 minutes. Hold at 40V for 20 minutes. 40-50V in 5 minutes and holding at 50V for 5 minutes and then 50-0V within 1 minute.

Sealing parameter: DM water( pH: 4-6) at >96*C for 40 minutes, but we are doing it for only 30 minutes ( if we are dipping the parts for longer duration they are turning to dark brown colour)

We are getting more and more AA 2219 for chromic acid anodising.

Can anyone suggest what wrong I'm doing. Any advice would be welcome.

Shop employee - INDIA

December 8, 2022

A. Hi Tarun

I suppose my first question back to you is... what does too dark mean? Too dark compared to past production runs, too dark compared to an existing or approved color sample? I can tell you that color will change as more thickness is added. Color may also change based upon alloy being processed.

I do not normally see thickness build up much beyond the .0002" so maybe you are surpassing that by quite a bit. According to MIL-A-8625 / MIL-PRF-8625

[⇦ this spec on DLA] the thickness range is .00002/.0007. (I have no clue about anything when it comes to metric) so i cannot respond as such. I am familiar with process times being 40 volts for about 1 hour give or take. I am also familiar with low voltage of ramping up 5 volts per minute until you reach 22 volts and processing for about 35 minutes.

I would question what is the reason/logic/benefit of processing at 50 volts for the length of time that you are doing. Is this somebody's spec? is this the way you have always processed chromic? I can understand cutting down the time on the final hot water seal as it is perfectly understandable that the parts turn brown in such hot water for that duration of time.

So back to my original question ... has something changed with the current batch of parts processed as opposed to how parts have been processed in the past that causes you to say the parts are too dark. There is a difference between saying the parts are dark as opposed to saying the parts are too dark.

supervisor - Cicero, Illinois

Saporito Finishing Co.

A. 1. The Mil Spec recommends not chromic acid anodizing any alloy over 5% copper "unless otherwise requested".

2. In 1957 in their Aluminite booklet, Alcoa found that chromic acid anodizing is deteriorated with sealing over 15 minutes in hot water, the Mil spec never acknowledged that, but Boeing did recognize and added a smidgen of chromic acid to the hot water - which works.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Thank you Mr Philip and Mr Robert for your responses.

Processing at 50V for 40 minutes is our customer specification. Sorry I mentioned too dark ... I mean parts turn to brown (as seen in image.. attached) after sealing at 97 °C for 40 minutes to all production runs. So, we cut down the sealing time to 25 - 30 minutes.

Does more cathode area while anodising cause this kind of problems? If so, do I need to change or replace the anodising solution (chromic acid) for next production runs?

(I have gone through process records of our last year production runs; here I observed in most of the batches Anode/cathode ratio is 1/3 or 1/4 )

Thank you again

Tarun Reddy [returning]- INDIA

December 16, 2022

Q, A, or Comment on THIS thread -or- Start a NEW Thread