-----

Corten Steel -- Q&A, Applications, Problems

< Prev. page (You're on the last page of the thread)

Q. Does Corten Steel or the rusting produce any OFF GASES?

Can the rust be toxic? I'm concerned about using it in a Sauna.

I considering using Corten for my outdoor Sauna as a protective Heat shield to protect the walls beside my Wood burning stove. I like the simple look just want to ensure Corten does not produce any harmful gases or toxins.

Please kindly advise if you have any advice.

Sincerely,

- North Vancouver, BC, Canada

July 8, 2014

A. Hi Christian. Corten weathering steel involves a small amount of alloying metals to help the rust be more adherent. There are no toxic off-gasses or corrosion products that I've ever heard of, and the heat shields should not get very hot (don't fasten them tight against a plaster or wood wall, mount them on standoffs an inch away from the wall and an inch or more off the floor to allow airspace between them and the wall so they function as radiators and the heat is transferred mostly to the air rather than the wall).

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I heard that if you Sandblast Corten Steel it encourages and speeds up the aging effects?

Where I live they have a "UBlast" facility and I've been considering Sandblasting to help encourage the orange to brown effect. Its only $35.00 to blast, I was considering this approach rather that using acids etc.

Do you believe this is a logical/good approach in terms of helping the Steel age faster. The Steel will be in a steamy Sauna the rest of its life.

Cheers,

Christian

- North Vancouver, British Columbia, Canada

September 15, 2014

Q. I have an angled 2 story window that is 12 inches deep on the right side and 18 inches deep on the left side

I would like to have this window trimmed on both the front face and the sides in Corten steel.

What is the recommended thickness to maintain a flat plane while still being manageable for on-site bending and cutting?

Lastly, what is the recommended means for attaching the Corten to the structure - does it need baffles?

- Carlisle, Massachusetts USA

September 20, 2014

Q. Great thread, really enjoy the information. I recently installed a Corten fireplace surround and one of the work crews leaned up against the steel and left hand prints. A strong muriatic acid solution had already been applied and the surface was brushed with a wire brush to remove the flaking and hopefully the hand prints however, they are still very visible.

How do I remove the hand prints? Thanks!

Roger Andrews- Dallas, Texas USA

October 20, 2014

A. A continuous repeated application of a simple acidic solution, lemon juice and water if you like, will cover up the handprints in a matter of weeks ,be sure to allow to dry between apps). However, you might find that the treated area appears differently colored in the long-term. I personally, would simply keep the area damp then dry, damp then dry, and so on until the affected area catches back up with the surrounding. Until then, it will just have to make for good conversation.

Good Luck!

- SLC, Utah, USA

July 29, 2023

Tip: This forum was created to build camaraderie through sharing of tips, opinions, pics & personalities.

The operator & readers who are here for that often won't engage with anonymous posters.

Q. I was wondering if anyone knows if Corten steel can be extruded? I know it is possible to Hot extrude some steels - is this possible with Corten? - the profile looking to be extruded is large, flat, thick and simple. Unlike a detailed thin aluminium extrusion.

Stefan Posthuma- Narrabundah, ACT, Australia

October 25, 2014

Q. We're looking at a "Corten" type weathering steel for a landscape edging application. Any advice on finishing to the top so it is not sharp? My guess is that most commercial products that might powdercoat a color will have a naturally "dull" edge through the powdercoating. How do we create a safe edge without rolling the edge and lose that minimal look? I'm concerned if it is bordering a walkway that someone might step on it without shoes.

Thanks

Landscaping - Los Angeles, California USA

November 4, 2014

Q. I'm a steel fabricator in Los Angeles, interested in creating a raised garden bed. I've seen 1/2" Cor Ten plate used for this, to build a box filled with soil.

What is a cost effective method to cut the 1/2" plate to preserve the weathering qualities of the steel?

Will flame cutting (laser, plasma, flame) require the cut edge to be ground to 'clean' steel?

SPECIALTY STEEL CONTRACTOR - COMPTON, California, USA

November 17, 2014

Sealant Bond to Corten Steel

Q. We need to apply a continuous sealant fillet along the top of a roof membrane termination bar on the side of a large roof top Corten steel planter. What preparation to the steel surface is necessary if any prior to applying a building silicone sealant to the steel to achieve long term adhesion?

Robert TrahanArchitect - Seattle Washington

February 11, 2015

Q. I have had very good luck sealing rusty surfaces - both Corten and ordinary mild steel with Por-15 Clear

[adv: Por-15 2k Clearcoat on

eBay or

Amazon [affil link]

. It leaves a slight gloss and touch of Amber, but is extremely durable and shows the natural iron oxide color very well.

It is quite pricey, however, and I'd love to hear about a more economical option.

- Berkeley, California, USA

March 20, 2015

![]() Hello Berkley Choate. I'd really like to dialog with you about Por-15 clear coat since I have a corten project I need to seal. Please reply to this message if you are still active here. Thank you.

Hello Berkley Choate. I'd really like to dialog with you about Por-15 clear coat since I have a corten project I need to seal. Please reply to this message if you are still active here. Thank you.

- South St. Paul, Minnesota

July 13, 2023

Q. Hi. Will the corten steel run-off contaminate the surrounding vegetation and waterbody if I used it as the material of a bridge?

Limay Foo- Johor Bahru, Johor, Malaysia

April 4, 2015

A. Hi Limay. Corten lasts longer than other steel because its rust is more stable and less prone to powdering off. Iron makes up 6% of the earth's crust, so a little rust washing off of things sounds pretty harmless.

However, if the bridge is over salt water you might want to investigate Corten's resistance to salt water first.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

April 2015

Effect of plasma cutting on Cor-ten

Q. Hi

I want to cut letters out of Cor-Ten steel sheet using a plasma cutter. What effect if any, will that have on the "decorative rust" finish on the steel?

Forest Iron Works - Locust Valley, New York USA

December 7, 2015

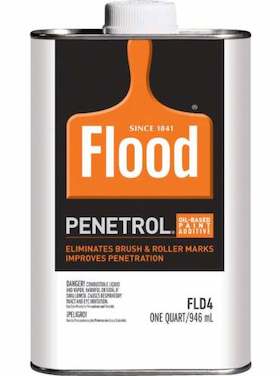

Q. I had corten steel panels installed on my patio to serve as a privacy fence and a backdrop to a firepit. Our climate is 4 Seasons hot in the summer, cold in the winter. My contractor has left me on my own now to figure how to solve the problem.

The panels were sprayed with some sort of rust accelerant then sealed with penetrol. The surface has bubbled and blistered and have popped and now show a rusted finish underneath in small spots all over the panels, the finish is very erratic and not nice. Would like to know how to take it back to original and

finish it with some paint or some other finish.

Thank you, Karen

- Wenatchee, Washington USA

June 29, 2016

Q. Good day,

I am currently a masters student at the University of Stellenbosch. I am working on a project and would like to know whether it would be possible to use corten steel in a stamping process? I would like to form shells for a tube.

- Stellenbosch, Western Cape, South Africa

August 30, 2016

A. Hi Robert. Because weathering steel is similar to other steels (about 1/2% of chrome and copper added though), I don't see any reason it shouldn't be stampable.

By this point in your education, you probably realize that the best way to learn is by trying to teach! So, as a Masters' student working with Corten, please try to answer one of the many unanswered questions on this thread. Thanks!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Remove rub marks & handprints from Corten steel

Q. Hi - I saw a question asked on how to remove hand prints on rusted corten. I have a similar situation of rub marks that I want to remove. It looks "cloudy" with these rub marks next to the normal rusted steel patina affect. So what is the best way to remove rub marks / handprints so you get the nice rusted steel patina again?

Any suggestions would be great.

Not sure if oxalic acid might help as a way to remove marks, then rust again?

- Melbourne, Victoria, Australia

September 18, 2016

Q. My question relates to the removal of fingerprints from corten steel, without starting the patination process. I have installed a corten sculpture in an art gallery in its unrusted state, not knowing if a potential buyer will want to display it indoors or outdoors. The fingerprints are unsightly, and spoil the clean effect of the work. How can I remove them? I have seen similar questions on this thread, but no answers.

Lizzie HorneSculptor - New south Wales, Australia

November 8, 2016

Q. Does anyone know where I can get Corten round head rivets or threaded bolt. There not a structural component just need for aesthetics, thanks

Mary Barrett- Limerick Ireland

December 2, 2016

A. I am also looking at using bolts to join Corten and I don't think you can get these made of corten. So I am going to either paint the heads or get some that will rust. They won't last as long as corten but I think they will do the job. By the way I only live up the road from Limerick. What a coincidence!

Joe Griffin- Mountshannon, Clare, Ireland

December 6, 2016

Q. I'm gathering information for welding Corten with a mig machine. There seems to be a split from standard welding wire to high alloy fillers. My sculptures are 3 feet more or less. I'm mostly concerned with color match. 14 gauge with one pass in what I`ll be doing, some 12 gauge.I`ld appreciate some input. Thank you, Ken

Ken Engelhardmetalsculpt - Pacifica, California, USA

December 19, 2016

Q. I have provided a number of Corten steel bollards to a public area. I got them from Spain. The rust is actually chipping / flaking off? Is this normal? I thought the idea was to get a patina finish rather than chipping?

rachel cowgilllighting - manchester england

March 30, 2017

Q. Hi!

I am a student of architecture in Croatia and my current project in class is an art gallery which is lined with Corten. I was wondering if anybody would know something about using Corten as a walkable surface and if there is a way of protecting the material and the people who would walk over it?

Thank you in advance! :)

University of architecture, Split - Split, Croatia

May 14, 2017

A. Hi Kristina. I'm certainly no expert on weathering steel, but it seems to be 97%+ iron, with about 2.5 to 3% combined manganese, copper, chrome, and nickel. In other words, it's not terribly different from hot rolled low carbon steel, just better at producing a stable corrosion product to slow the continued rusting.

Sheets of steel would not seem to me to be a good public walking surface, as they might be slick, although probably fine as some sort of perforated or expanded metal grating. But if you do a Google image search for "Corten as walking surface", I think you'll find many examples that you can further investigate. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Will Corten near roofline stain our siding?

Q. Hello All,

Can anyone tell me if corten, once it is rusted will bleed onto surfaces next to it? We built a house that has a band or strip of corten along the entire length of the house just under the roof. It's beautiful and I really like it. I did have some concern that it might get wet and then bleed down the painted siding of the house. The house is built under a canopy so it is largely protected, but we do get that terrible sideways rain here in east Texas and it can get wet. The builder assured me it will not run, but I am not sure I believe him. I do not believe this metal was pretreated with anything either.

Thank you for you help and advice.

- Cayuga, Texas, USA

August 21, 2017

A. Hi Carran. Life is complicated, and oftentimes we must take our best guess. I doubt that the many people on this page who are complaining of Corten staining are lying, but I'll bet also that your builder has some local and relevant experience with it.

Your town is well away from the ocean, thus minimizing the problem. Your painted siding is a relatively slick surface compared to porous concrete, and it will be exposed to that same "terrible sideways rain", helping to wash down any rust. My guess is that your builder is not talking through his hat, but has found that it is unlikely to be a serious staining problem for you in this particular application.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

August 2017

Q. Hello!

I am working on creating a new sign for my business. It is Corten steel back with stainless steel letters. I had a fabricator create everything for me, but I have to put it all together myself. The idea was for the stainless letters to sit atop the rusty steel back. (The letters will sit 1" out so as to look more 3D.) When I picked up the steel back it was not rusted and they wanted to charge me an extra $425 to do it, but told me it would rust up over time, but could 6 months or more. They then told me I could just give it a spray with muriatic acid and then come back a few hours later and it would be all rusted. Well I did this and it turned out very blotchy with large areas that are really dark brown, rather than a beautiful orangey rusted patina. I did wash it down the next day with water.

My question is if I just leave it at this point will the patina continue over time and maybe become a little more uniform and maybe get a lighter rust over these dark spots or will these dark brown areas stay like this forever unless I grind it all back down again and start fresh? The sign is 16' long and 32" tall, (It is in two pieces) so that would be a lot of grinding!

Cristi Mason-Rivera- Mcminnville, Oregon

September 1, 2017

A. Hi Cristi. Many metals can last a long time out in the world, not because the metal itself is corrosion resistant, but because its corrosion products tend to build into a somewhat impervious coating that tends to cover the surface and thus limit water and air from reaching the raw metal, and thereby slow down the corrosion. This is true of aluminum, zinc, copper, stainless steel, etc.

Steel does not enjoy this sort of corrosion resistance benefit because its corrosion product, rust, continues to slough right off, and the surface is hygroscopic, holding on to water and causing continuing corrosion.

But steel is much much cheaper than other construction materials on a strength for strength basis. The intent of Corten steel, as I understand it, was simply to formulate an inexpensive steel that is somewhat more resistant to deterioration than regular steel by virtue of a tighter-adhering, more impervious rusted surface.

Corten is a structural material, it's not a decorative finish, so it can be optimistic to expect a stain-free highly decorative appearance. Sometimes it's just hope for the best. The stains on your sign will probably not go away, and the most consistent results will probably be had by sodablasting [soda blaster on

eBay

or

Amazon [affil link] the surface and then simply allowing it to rust. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

September 2017

Q. I would like to know if using Corten steel in a fire pit design will negate the rust arresting properties of the metal.

I.e., is the price worth it to use Corten vs normal steel plate for fire pit construction.

Construction:

3mm plate (stamped into a bowl shape)

max heat zone ~800 °C (around the water drainage hole in the center of the firepit bowl)

- Balgach, SG, Switzerland

September 12, 2017

A. Hi Alex. Cost wise, steel painted with stove and BBQ paint

⇦ on

eBay or

Amazon [affil link]

would be the way to go, but if you want the raw steel look, the bowl will probably not have a fire in it 99% of the time, so I think Corten might be worth it.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. We are in the process of building a contemporary style home using cement board for exterior and corten at the front entrance and around the back view windows. After reading these posts I am very concerned about the idea of corten. I love the look of it, any suggestions that will work in place of Corten and still give the "look"? Thank you.

Kimberli Byrne- Auburn, Washington, USA

September 14, 2017

A. To the people questioning about streaking, mottled or inconsistent oxidizing patterns. It is in my opinion (whatever that's worth) that it is due to not blasting and/or solvent cleaning the raw plate surface before letting the surface oxide to form. During the sheet manufacturing (rolling at the mill) the surface layer may have inconsistent scale and/or oils on the surface. These of course, one would expect, need to be removed consistently to allow the climate (or any patina enhancer/accelerant)to effect the surface uniformly.

To those questioning about finger prints/hand prints etc. These of course are likely due to acids and oils from ones hands again interrupting a uniform condition on the surface. I doubt there is an easy answer other than blasting or otherwise etching the surface. If it is going to be touched, a protective coating of some type of oil or wax (as mentioned by others) should be applied.

Thanks everyone who has shared their experiences and problems with Corten weathering steel. I am currently researching the use of the material for a farm gate sign and some landscape pieces.

- Niagara Falls, ON Canada

Q. Hi there, I'm desperate for help with a COR-TEN steel planter that I bought recently for my home. It is designed to rust over time outside or you can rust it yourself by spraying a mix of peroxide ⇦ on eBay or Amazon [affil link] , white vinegar ⇦in bulk on eBay or Amazon [affil link] and salt. I rusted the planter myself. I did 6 applications and achieved the rust patina I was looking for.

The problem I have is … this planter will be in my home and when you touch it, the rust comes off onto your hand and clothes. Kind of like a rusty dust. Not chips of rust or anything like that. This rusty dust of course doesn't work for me as the planter is in a walkway, so I am trying to find a matte clear finish to coat this planter, to stop the rusty dust from coming off when touched. The company I bought the planter from advised me to use Everbrite Crystal clear coating. I bought the aerosol spray. After only one coat (I was told to apply 3-4 coats since it's rust I am coating and its quite porous) it changed the color drastically :(

It made it way darker than the original color and you could see a bunch of streak marks going across the planter where my husband had sprayed it. I was told it wouldn't change the color and read in their info that the "lines" of clear coating would disappear when it dried, but it didn't. I was so disappointed that it changed the color so drastically. I was in love with the original color and wanted to keep that look.

So, I had to sand the planter down and take the Everbrite coating off plus a lot of the rust patina to start the rusting process over. I have sprayed it down again to the desired rust patina and I'm hoping someone knows of a clear matte product I can use that won't change the color AT ALL and will also seal the planter so that rust doesn't rub off onto our hands and clothes. Also, before I put a product on it to seal it, do I need to wash the planter down with baking soda and warm water? I read in some of the previous comments that this needs to be done before a clear coat is put on? Is this the case for me too? If so, how much baking soda and how much water need to be mixed together? Thanks in advance and hope you can help!

Karen Cooper- Bracebridge Ont Canada

July 15, 2018

A. Hi Karen. Sorry for your disappointment! Unfortunately I think you will get the same result no matter what clearcoat you apply -- because the problem isn't that the clearcoat was tinted and lacking in clarity. The problem is that the lighter, diffuse, color you had achieved before clearcoating was the result of the surface topography: a field packed with miniature/microscopic rust boulders scattering the light in every direction. When you submerge those boulders in a clearcoat the look is different (if you've ever collected sea glass or beach pebbles you'll notice that they are dull and matte-looking when dry but bright and shiny as long as they're in water).

You might try a paint specially made to look like Corten, or see if a rust colored patinating solution ⇨

gives you the look you seek (those approaches have at least two parts: first, apply the metallic surfacer with the iron particles in it , then follow that with the rust activator, but usually an acid-blocking primer first, and sometimes a clearcoat after.

Baking soda [in bulk on eBay or Amazon [affil link] is a neutralizing solution for acids and it doesn't matter how strong or dilute you make it as long as there is enough baking soda in total to neutralize however much acid was left on it … and it was probably very little; I'd be pretty confident that half of a small box in a half gallon of water would be enough.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Thanks Ted! I'm disappointed to hear that most likely every product I use will make the rust look darker. What about a matte finish Polyurethane with thin coats? Would that have different results you think as far as the color goes? I saw that product mentioned to use various times on this thread. And which product overall would you say is best to use as far as a great clear topcoat. I don't want anything that will bubble or peel or show lines from spraying or painting it on. Just a nice clean clear coat. The planter is 30 inches tall x 38 inches wide. I also want it to keep moisture out and of course prevent more rusting from happening. I will for sure wash it down with baking soda and water first before applying a top coat.

P.S. Also, I forgot to ask … to get the best smoothness and to get the product applied evenly on the planter, what is best to use? A paint brush or roller? Or both? Thanks so much!

- Bracebridge Ont Canada

A. Hi Karen. To the degree possible, we try to suggest types of finishes not brand names (why?)

The manufacturers of super-quality chandeliers spray six or even more layers of very highly thinned clearcoats, so the secret to smoothness is multiple highly thinned layers, whether brushed or rolled or sprayed.

The only thing I can suggest at this point is to get another piece of Cor-Ten steel and do your experiments on a small piece, or multiple experiments each in a small area of a big piece. Conjecture gets us only so far, and you don't want to keep instantly ruining your carefully finished piece with experiments, but I have tried to explain why clear-coated rust won't look like bare rust. Best of luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Okay I completely understand :)

Thanks for the tip about testing on a small piece of steel. I have a corten steel shelf that fits inside for the plants so I will rust that to the same color and then test products on that.

Last question, I really appreciate your input. When I wash the planter with baking soda and warm water, which is the best way to do it? Do I spray it on? Mix it in a bucket and dump it over the planter? Or do I use a cloth and keep dunking that in the baking soda water and just keep wiping down the entire planter with the cloth?

And secondly, do I rinse the planter with water after I have washed it down in baking soda and water?

P.S.I also forgot to ask about what product is best to use to smooth out the surface of the entire planter before I put a clear coat on it? Right now you see the natural "rain lines" from the peroxide, vinegar and salt spray running down it. It dried that way. I would like to smooth out the surface so that you don't see all that. What would you recommend to use that won't necessarily take off a layer of rust? I need something more gentle that will just smooth it all out and give it a nice smooth appearance on the sides of the planter? Thanks so much!

Thank you so much! :)

- Bracebridge Ont Canada

A. Hi again. It is the baking soda [in bulk on eBay or Amazon [affil link] , not the water it is dissolved in, which reacts with and neutralizes the acid. So how you neutralize the small amount of remaining acid with baking soda probably doesn't matter much. But whichever way, neutralization creates carbon dioxide gas; so if you see fizzing, the acid is not quite neutralized yet. The baking soda should be rinsed off before doing the clear coating, and probably dried.

I don't have any real experience in trying this 'smoothing' idea, and you can see on the thread that others have difficulty getting a uniform finish. I suppose you could try a light steel wooling with a very fine grade (#0000 steel wool ⇦ on eBay or Amazon [affil link] ). As for limiting the streaking when your treatment chemical dries, maybe try a little dish detergent in it to make it wetter.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. If you want to preserve colour of Corten patina you must use very diluted Paraloid B 44 ⇦[paraloid on eBay affil link] clearcoat (1,5 - 2 % = 15 - 20 grams on 1 lit toluene or acetone ⇦ on eBay or Amazon [affil link] Flammable! ). Very diluted 'water glass' ⇦ on eBay or Amazon [affil link] can be an option too. Some testing on small corten plates can be helpful. Hope it helps and good luck!

Goran Budija- Zagreb,Croatia

July 25, 2018

Comment: I am a sheet metal fabricator who has only done a couple of jobs with Weathering Steel to date so I am not an authority. I have spent much time looking at jobs done with this steel, however, and I will say that if you weld it you need to sand your welds up to a good finish if you want a flat face without gouges in it. Finish them with an orbital sander. It is also critical that you use a compatible welding electrode of the same composition as the parent metal. After that sandblast it back to a matte finish all over. This is very important as you need to start with a uniform matt finish right across the job or piece you are making. All of the mill-scale needs to be removed otherwise it will form a patina with black patches in it. These will vary depending on the thickness of the layer of mill-scale. Ultimately it will get a uniform colouring after about 2 to 3 years if you don't do this. But you can achieve that uniformity of finish sooner if you start with a sandblasted matte finish at the beginning.

As to bleeding or leaching it is very very minor. I have my garden fence on white gravel and there is little to no colouration on the stones. It is nothing like you will get with Mild Steel.

It will get marks on it from bird excrement and if you try to wash this off it will leave scrub marks, where you cleaned it, which are very discernible. Leave it alone.

I have seen examples of people trying to speed the patination process up with chemicals but they generally look hideous. Especially if you are not a professional with much experience. They always have streak marks to varying degrees. My comment would be to just leave it alone and let it colour up at its own rate. Period!

- Rangiora, New Zealand

October 2, 2018

Q. I'm planning on building a Corten flat panel fence 7 ft tall. What gauge panels should I go with? FYI I will have more than enough support beams to get it sturdy. Thanks.

David Zarate- Modest California USA

March 5, 2019

Q. : I am making a metal bench from Corten steel. Can I make the seat not leave stains on people who sit on this? Is there a finish that will not change the look of the Corten.

Thank you

- Winnipeg, MB Canada

May 8, 2019

A. Hi Ryan. On a drive just this week I was noting that a disadvantage of Corten guardrails is that bad rust stains were running down the curbs and concrete roads even without friction and rubbing. The Corten itself looks okay, and if the guard rails are just over earth, probably okay; but the rust stains on the concrete are ugly. This shouldn't have been a big surprise to me as the brown coloration is, of course, rust. Some people experience very little rust staining, and I'm not sure why those guardrails seemed so prone to it.

There are paints which are designed to look like Corten and I think they'd be a better bet for a bench. But you can try a thin single-component clearcoat on your Corten, perhaps as Goran suggests, although I think it will be at best only partially satisfactory. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

May 2019

Q. I want to use Corten steel panels for an interior fireplace wall. The question is how best to install/affix them to the wall. Anyone done this in No. Virginia?

Alex Tab- Fairfax, Virginia

February 17, 2022

A. Hi Alex. I may not be understanding what you are trying to do when you say 'fireplace wall'. If they are strictly decorative pieces mounted on a wall near a brick fireplace and intended as artwork, you can probably attach them either with glue or screws.

But if you are using them as some sort of heat shield, such as behind a wood burning stove, you want them to return the radiant heat which they absorb back into the room, not pass it on to the plasterboard behind it. To do that you need to use some sort of 'standoffs' to create an inch or so gap between the sheet & the wall, and the sheet & the floor so air will cool both sides of the sheet, and the wall.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. We have used Corten steel materials in a few of our projects. We are facing some issues like water stain or water mark / moisture marks on planters and sculptures installed outdoors.

Is there any possibility to remove these water marks as part of preventive or corrective maintenance?

Please, requesting experts advice.

qc incharge - uae

August 3, 2022

A.

www.richard-brink.de/fileadmin/user_upload/download/pdfs/Materialhinweise/RB_Materialhinweise_Corten_E.pdf

Hope it helps and good luck!

- Cerovski vrh Croatia

August 17, 2022

A. Cleaning and caring for COR-TEN steel products:

"Once the patina layer is formed, COR-TEN steel is extremely low maintenance. Nevertheless, we recommend cleaning the surface regularly and checking it for any changes (once or twice a year).

• Do not using cleaning agents to clean the material. It is generally sufficient to lightly brush the surface in order to remove soiling.

• Never use cleaning agents containing chlorine.

• Use non-ferrous cleaning tools; never touch the surfaces of the material with non-rust-proof tools (scraper, file, etc.), ferrous sponges or non-rust-proof steel wool.

• Remove protective films early, as otherwise the film and steel surface may bond. Remove adhesive residues with spirit. Warming it up slightly makes removal easier.

• Dissolve scale and grout spots with phosphoric acid and rinse with clear water. Never use cement film remover or diluted hydrochloric acid.

• Avoid strong heat transfer to the material (e.g. from working with an angle grinder, drilling without emulsion, or from plasma cutting, the effects of fire, etc.)

• Do not allow sparks to touch COR-TEN steel surfaces.

• Freshly welded areas must be suitably cured.

• Ferrous particles must be removed immediately, as they can penetrate the passive layer of the COR-TEN steel and cause corrosion. Ferrite-free cleaning sponges or similar can be used for this purpose. If corrosion has already occurred, a pickling treatment may be necessary.

• Remove surface rust immediately.

• Avoid contact with salt.

• Oil and grease can be removed with organic cleaning agents. All cleaning agent residues must be removed.

• Residual paint can be removed with an alkaline or solvent-based cleaning agent. All cleaning agent residues must be removed.

• Avoid extraneous rust:

- Work on steel and COR-TEN steel in physically separate areas.

- Use separate tools for COR-TEN steel or ensure that tools are completely free of ferrous particles.

- Do not use transport equipment or hoisting equipment made of steel (forklift etc.), or if such equipment is used, protect the COR-TEN steel products accordingly using protective covers."

(According to previous link!)

- Cerovski vrh Croatia

August 31, 2022

Q. Hi,

I have a corten steel design fence. The patina became nice and brown in a few months time. But now it seems to blister. Bubbles show up and the nice brown patina falls off.

Corten is known for the self healing of the patina.

Is this a normal process that blisters show up then fall off?

Jean

- IJmuiden, Netherlands

December 17, 2022

Q, A, or Comment on THIS thread -or- Start a NEW Thread