-----

How to do nickel acetate sealing

Readers who want a quick introduction to anodizing of aluminum, please see our "Aluminum Anodizing: Intro & FAQs".Nickel acetate sealing is one of several possible sealing methods, widely used on dyed/colored anodizing; its advantages include lower operating temperature than steam sealing or boiling DI water sealing, and less likelihood of leaching of dye from the anodizing.

Phosphate Contamination in Nickel Acetate Seal

Q. We have an issue where I work with the nickel acetate seal leeching color out of type II anodized, dyed parts. Early in my career I worked at a shop that tested for phosphate contamination in our nickel seals, but it's been 20+ years since then, and method of testing and PPM limits have long since escaped my memory.

Matthew S.Employee - Illinois

August 14, 2025

Tip: Readers are welcome to browse this site anonymously!

But its main purpose is to build worldwide camaraderie through sharing.

Those who believe in this might not engage with anonymous posters.

A. Hi Matt,

Not sure you need to check for the contamination because your proof is already there, but it may be just a matter of what the seal is contaminated with. It really does not matter how much of whatever is in the bath but rather what is in it that is giving you the headache. pH is a critical factor for proper sealing as is nickel concentration.

Cleanliness of the seal is important and at least two things contribute to this:

• How clean are the rinses ... all of them. (What is the benefit of rinsing in dirty rinses?)

I have seen caustic play the part of the culprit, yes, all the way down to the nickel.

By the way, that hot seal has a way of loosening up contaminants that may not have been rinsed out of the parts properly.

Poor rinsing contributes to so many woes and headaches in the anodize process. Poor rinsing is going to introduce contaminants into the seal which is ultimately going to affect the pH. A high pH lends itself to caustic contamination and low pH speaks to acidic contamination. This is just coming from the anodic process never mind how well your customer did or did not clean the parts prior to you receiving them.

I have also seen a low nickel concentration contribute to color leaching. Anyhow, keep an eye on the pH. You are probably using ammonia to raise it when it is low and acetic acid to lower it when it is high.

Temperature is important as well. If you are using a mid to high range seal, then when the tank travels towards cold (meaning 10 or more degrees under operating temp, this can have the same effect on parts that you are currently encountering, color compromise.)

You can also have issues from your water supply. If you are using city water as opposed to D.I. water there are additives which can cause you headaches such as excessive chlorine content. While the chances of this are slim, it can still happen

The proof of the pudding is in the eating. Poor maintenance of the baths, be it by design or otherwise, is going to lend itself to anodizing headaches. There are a myriad of issues which are encountered during the anodize process, some are beyond our control and some are not. You would do well to tend to the ones that you can.

Retired - newport, tennessee

August 18, 2025

⇩ Related postings, oldest first ⇩

Q. We currently warm seal anodized aluminium extrusions in water at approx. 100 °C (212 °F). I understand that appropriate quantities of nickel acetate will help the sealing process. Could someone explain how it works? How much nickel acetate should we add? How can we check the concentration of nickel acetate?

Thanks

- Bombay, India

1996

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

on eBay or Amazon

or AbeBooks

(affil link)

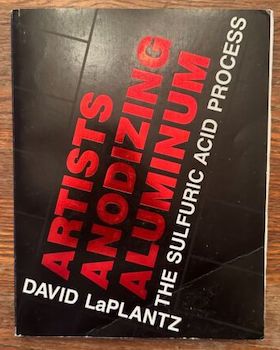

The Sulfuric Acid Process"

by David LaPlantz

on eBay or Amazon

or AbeBooks

(affil link)

A. Nickel sealing is often used for dyed anodic oxides, since it is colorless. The corrosion resistance afforded by the process is generally not as good as boiling water or steam seal, unless the nickel acetate process is done at boiling temp. Cobalt acetate may also be used. A practice [mix] found in

The Surface Treatment & Finishing of Aluminum and its Alloys by S. Wernick, R. Pinner, P.G. Sheasby is:

5 g/l nickel acetate, 1 g/l cobalt acetate, 8 g/l boric acid (in distilled water) for 15-20 min at 70-90 °C and pH 5-6.

Alcoa Center, Pennsylvania

A. You might want to review the following two references which explain what occurs during sealing and provide information on seal bath make-up:

1. "Sealing of Aluminum and its Alloys," Roy C. Spooner,

Metal Finishing, December 1968, page

44.

2. "Sealing of Anodized Aluminum -- A Review," Benjamin Yaffe, Metal Finishing, May 1990, page 41.

In order to determine the nickel acetate concentration in a solution, we use the following method:

Reagents:

EDTA (21.4 g/l = 0.0575 M)

Ammonium Hydroxide

murexide

[affil link] (0.2 g Murexide to 100 g NaCl)

Procedure:

Take a 2 ml sample in a 250 ml Erlenmeyer flask and 50-75 ml of water. Add 10 ml ammonium hydroxide. Add a pinch of murexide and titrate with 0.0575 M EDTA to a blue-purple endpoint.

Calculation:

oz/gal Ni Acetate = mls EDTA x .678

aerospace - Windsor Locks, Connecticut

A. Nickel acetate works as as catalyst in the sealing process. Also, the nickel ions are incorporated into the pores on your coating, which is why the nickel acetate bath can seal anodized aluminum more quickly than water alone. The nickel ion basically blocks or fills up the opening to the pore.

Also, nickel acetate will not leach the color out of your dyed parts, which makes it very effective in dyeing operations.

- Streamwood, Illinois

Experiencing a color shift when sealing anodized parts

Q. We experienced from batch to batch a color shift during the sealing process. We use a nickel sealing salt at 96 C with pH at about 5.8. This black dye used is from Japan at a low concentration to produce a titanium shade. We do not have problems on dyeing but when it comes to seal problem starts there. Anybody has experience on such a problem and what are the reasons? What should we do to improve the situation?

S. Y. Yuen- Hong Kong, China

1998

Aluminum How-To

"Chromating - Anodizing - Hardcoating"

by Robert Probert

Also available in Spanish

You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

by Runge & Kaufman

on eBay or Amazon

or AbeBooks

(affil link)

A. There are a number of things that can cause leaching of dye into a nickel acetate sealing bath. if your seal bath contains a surfactant (and it probably does if it is a commercially available product) then this is a likely culprit. check with your supplier on this issue.

it is important to keep in mind that nickel salts will always leach some amount of dye from your parts. maintaining a proper coating thickness and dye bath chemistry will help eliminate differences between one batch and another. and finally, the dye you are using is not designed to deliver the color you want. using a lower dye concentration will cause inconsistencies in the color that are not visible until after the part has been dried, and these inconsistencies may be independent of your seal bath. I would suggest you try a dye or dye combination designed to deliver the color you are after. contact Clariant Corp. in Charlotte, SC (or is it NC?) as they are the leader in dye manufacturing for anodized aluminum.

Gerald Janssen-coil anodizing - Streamwood, Illinois, USA

A. Color matching is difficult, and requires very good process control of the anodizing process to start with because small changes in concentration of the electrolyte, temperature and current density, as well as ramp rate parameters affect the anodic pore dimensions and thickness. Then one needs to work with the customer to develop two samples which reflect the acceptable range of color. One sample is a light sample and one a dark sample and anything between the two is acceptable. Of Course both the process house and the customer have a set of these samples. That said, because the dye bath and the seal work in combination, with color impregnated and color leached out, usually a beginning production run of the day will be used to determine both the times in the dye and in the seal. Those times will change sometimes hourly, and when very critical appearance dye parts are to be run, the dye and seal times may need to be established from batch to batch! Naturally, both the dye bath and seal parameters need to be maintained very tightly.

Ward Barcafer, CEFaerospace - Wichita, Kansas

A. Mr. Janssen and Mr. Barcafer have stressed very important points, which many of us have learned through experience, and I believe the root problem is trying to dye parts grey with a dye that is designed for black (assuming that titanium refers to a metallic grey color.)

Experienced color matchers know this, but here is a factor to consider in case you are a novice- the proverbial comparing apples to apples. When you say you have no problems with the dye, I hope you are comparing apples to apples, that is, comparing wet parts to a wet standard, or dry parts to a dry standard. The water on parts as they leave the dye rinse will make the parts darker than they will look when dry, especially if the parts have a matte finish. It's basic optical physics where the water turns normally refracted (scattered) light into reflected light from a glossy surface.

Checking the actual in-process color vs. your color standard(s) can be done in two ways: several shops I have been in take an air hose and blow-dry a part or small section of a large part to check color vs.standards. Naturally the blow-off air must be completely oil-free. The other way is to compare two wet surfaces. A well-sealed color standard may not wet very well, plus the constant wetting can eventually change the color of the standard. I used to get around that by applying a water-white clear lacquer to half of one surface of my color standards. The lacquered surface has the color of a wet part. You may later need to worry about yellowing of the lacquer, but color standards need to be retired periodically for new ones anyway.

Another factor in matching colors: it goes without saying to do the color matching in a well lit area, but also consider that the color match should be done under the same light conditions as the lighting conditions where your customer will be looking at the parts. Colors can match under fluorescent lights, but can look different under incandescent or natural lighting. A prime example of this phenomenon is the color comparison between the old integral colored anodize and two-step electrolytic colored anodize. When the two-step process first broke into the market, there were many arguments over color matching.

As the two previous letters state, one can expect some degree of leaching in any seal, and you may find it beneficial to establish a "before seal" color standard slightly darker than the final color.

Phil Johnson

- Madison Heights, Michigan

A. An addition to Phil's comment.

We had a significant argument with a customer. Finally went to his place and looked. The cause of the difference of opinion was we used cool white fluorescent tubes set high, and they used warm white set lower. It made a big difference in what showed up. Replacing one bank of tubes solved all of the difference of opinion.

James Watts- Navarre, Florida

![]() James is so right about paying attention to lighting. One company I know of provided black anodized high-end audio equipment and encountered the problem that, in the faint light of darkened stages, their parts from one anodizer were red while parts from another anodizer were blue.

James is so right about paying attention to lighting. One company I know of provided black anodized high-end audio equipment and encountered the problem that, in the faint light of darkened stages, their parts from one anodizer were red while parts from another anodizer were blue.

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Although you mentioned that your sealing bath operating with pH 5.8, I do suggest that you better recheck your bath pH control. As far as I concerned, if your bath pH is too low, less than pH 5.0. Fluoride (might be part of the formulation) is too aggressive and at this moment, it would attack the boehmite film and eventually deteriorate the colour. Besides that, I also like to suggest that the sealing water quality have to be checked. If the sealing water quality is too bad, for example, silicate content is too high, more than 10 ppm, the sealing process is not efficient as the result, the color leached off.

Lim Heng Kam- Malaysia

Q. We are currently using a Nickel Acetate Seal Bath. It is only nickel acetate and a desmut agent in the bath. I see that you say to use cobalt acetate as well as boric acid. Could you explain the advantages of using these chemicals in addition to nickel acetate?

It says in The Surface Treatment and Finishing of Aluminum and Its Alloys, on page 894 that there is little or no difference between the nickel and cobalt salts, but are frequently used together.

Also when controlling the concentration of nickel acetate in the bath, are you trying to control the amount of Nickel Ion in the bath? Or are you trying to control the amount of Nickel Acetate in the bath.

Thanks, any help is appreciated.

⇐ answer?

- Boulder, Colorado, USA

August 1, 2012

Q, A, or Comment on THIS thread -or- Start a NEW Thread