-----

Help With Plating Tank Height Requirements

Q. I am dealing with a citation received from Cal/OSHA on the height of our cleaning tanks. These tanks are 32 to 34 inches high and OSHA is requiring us to raise them (or use guardrails) to 36 inches. Has anyone else out there run into this problem?

Another issue: Chrome in polishing and blasting stainless steel -- Carcinogenic?

LaVaughn D [last name deleted for privacy by Editor]- Arcadia, California, USA

A. Regarding tank height requirements, they do need to be raised or to have guard rails added, and not to 36" but to 42"! You can't win on this one unless if the tanks are so small that falling in would be impossible.

Although hexavalent chrome is carcinogenic (it is what the movie Erin Brockovich was about), hexavalent chrome is an acid -- not a metal. Stainless steel is a metal, and it is the FDA "material of choice" for food processing. What could possibly lead anyone, let alone a trained inspector, to thinking it is carcinogenic? You've misread the citation, or I've misread your inquiry. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Greetings - I need help! My company is currently considering an expansion. We are getting conflicting reports of tank height requirements for metal finishing facilities. Some tanks will be used in a hand line for racks weighing approx. 10-20 pounds. Other tanks will be used for barrel plating primarily. Are there any tank height requirements? Are they published anywhere? Many thanks for this great forum and all the helpful finishers out there!

Victor Waldman- Naugatuck, Connecticut USA

2001

Peter Drucker in one of his books asks/answers a question "How big should your company be" with the answer, that "Size should suit the function"! It's not very different with Plating Tanks. Depends on the Electrolyte. I like my Zinc Tanks deep as I let sleeping sludges lie. However my Nickel Tanks not deeper than 8 inches below the rack so as to get any residual waste into the filter and not lie in the tank. Also keeps the heating costs optimum and uniform till bottom.

Post more details about the process and component sizes.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

2001

2001

![]() Thanks KV. You interpreted Victor's question differently than I, but I always learn something from your knowledgable replies.

Thanks KV. You interpreted Victor's question differently than I, but I always learn something from your knowledgable replies.

A. In a word: 42", Victor

The longer answer is that there is an OSHA rule about walkways above pickling and galvanizing lines requiring standard 42" high railings ...

Regardless of height, open-sided floors, walkways, platforms, or runways above or adjacent to dangerous equipment, pickling or galvanizing tanks, degreasing units, and similar hazards shall be guarded with a standard railing and toe board.

This regulation has, by continuing usage and court interpretations, been extended to involve all plating lines. And rightfully so, I might add, because there have been many fatalities and injuries from workers falling into plating tanks at back of the knee height.

In the case of automated lines, barrel plating lines, etc., the best solution may be to put the rims at 42" and dispense with any railing. Most people, including OSHA inspectors and judges, appreciate that adding a railing to such an installation will add dangerous pinch points; and that if the danger of falling into the tank has been eliminated by setting the tank rims at 42" without adding any pinch points, that is a better solution.

For a manual line though, the ideal situation from an OSHA and liability standpoint, is usually to put the tank rims at a more workable height of say 30", and then put that standard pipe railing around them to 42" off the floor. I've seen this done and it can be very workable.

The advantage to this approach is that workers are protected to 42" as intended, but only need to raise the bottom of the plating racks 30" above the floor. I have seen manual installations with 42" tank rims where shorter workers end up climbing on a stool, or an upside down bucket or other poor excuse for a stool, and now find themselves right back into the possibility of being high enough to fall into the tank but now from the poor footing of a rickety "stool" :-(

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Ted,

I read with interest your response to an inquiry on plating tank heights in a recent Metal Finishing publication. I wonder if you wouldn't mind elaborating a little further on situations where this regulation has been applied to companies with tank heights of less than 42 inches.

The company I work for has automated electroplating/conversion coating lines. With the exception of one individual per line who monitors the chemistry and makes additions when required, there is very little work required around the tanks. The height of our tank rims is approximately 28 inches above the catwalk. The opposite side of the catwalk is protected by a 42-inch railing.

Have there been precedent setting rulings you are aware of, by the Standards Board, that compel the installation of higher protective railings? The company I work for has never had a related loss in 35 years, so I will need something compelling to present to management if we are to contemplate the modifications. Also, I was not able to visualize the setting where you described a 33-inch tank height with a 42-inch standard pipe railing around it. If the railing is immediately around the tank, it seems that the operator would still have to get the bottom of the rack 42 inches in the air to get it over the rail and into the tank.

I would appreciate any additional information you are able to provide.

Mark Smith- Santa Fe Springs, California, USA

2001

A. I will be happy to clarify, Mark.

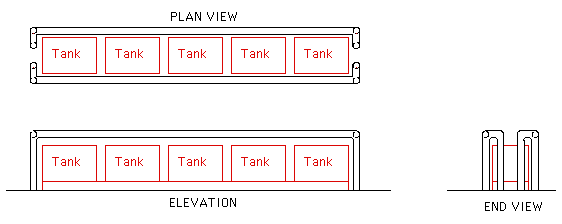

First, some people were confused by my statement "put the tank rims at a more workable height of say 30", and then put a standard pipe railing around them 42" off the floor", asking me how this saves the operator from having to lift the bottom of the work 42" off the floor. Well, these railings are along the rim area of the tanks, but if the tanks abut one another, there is no pipe railing between the tanks, so the wet drippy work need be lifted only above the rims:

For the rule itself, as printed, please see www.osha-slc.gov/OshStd_data/1910_0023.html#1910.23(c)(3)

As for my interpretation of the OSHA rule, please see www.osha-slc.gov/OshDoc/Interp_data/I19791129.html and I think you will infer the same things that I do. But if anyone is hurt by falling into a tank, an after-the-fact assertion that OSHA might have considered the violation "de minimis", had a variance actually been sought, sounds like pretty weak ground to stand on anyway. Having been an expert witness on the defense side of the table in several cases, I would not have been very comfortable had the tank rims neither been at 42" nor was there a railing.

Obviously, it's not possible to fall into a very small tank, but people used to fall into large plating tanks frequently in the old days when rims were 21" to 24" off the walkway and they got caught at the back of the knee. I am 6' 4" tall and to me 26 to 27 inches is still a back-of-the-knee problem (I just checked it with some low tables). 28" is getting into the "iffy" range. A height of 30" is obviously better, but who can argue that 33" to 36" or the European standard 1-meter is still better, but that the ideal is the same height you would want on any protective railing?

If you walked onto the balcony of a 10th floor hotel room and the railing was 28" or even 30", how comfortable would you feel? Plating tanks are often HOT enough to burn a person so severely in a few seconds that death is inevitable. You should feel no more comfortable standing next to a large 165 °F tank than you feel on a 10th floor balcony.

It's all just my opinion, and yours is welcomed.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2001

A. Hi Victor and Mark,

It sure seems that poor old Ted has gone to a lot of work for you people. Lucky you.

Regarding Ted's 2nd last para about tank heights, I cannot help thinking of the adage, RULES ARE TO BE (blindly?) OBEYED BY IDIOTS BUT ARE A GUIDE TO WISE MEN !

A good ergonomic access height is 36", i.e., a hair to two less than a meter.

In the case of fume hoods having large hotplates, they should not be over 30" high because the operator has to be able to easily access any beakers [beakers on eBay or Amazon [affil link] & petri dishes on the 6" or so high(er) hotplates.

Regarding hotel railings ... well, over here railings now have to be 42" but low level large plating tanks would frighten me. Never seen any, coming to think of it.

May I then suggest for small tanks you elevate to the good ergonomic height of 36" as this would make it much easier for the worker = increased productivity, too. For Asiatics, ah, you'd maybe need to be a few inches less.

Cheers !

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

![]() I'll bet most Americans saw the recent return of the spy plane crew, Freeman. Some crew members looked as big as linebackers, whereas one of the female crew members was small. I hope that crew isn't considering retiring to the plating industry. How can anyone design an ergonomically correct manual plating line considering things like that?

I'll bet most Americans saw the recent return of the spy plane crew, Freeman. Some crew members looked as big as linebackers, whereas one of the female crew members was small. I hope that crew isn't considering retiring to the plating industry. How can anyone design an ergonomically correct manual plating line considering things like that?

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2001

2001

(In reply to Ted Mooney's last rejoinder)

Sir!

I doubt very much that the crew of the spy plane would be as tall as you give yourself to be, i.e. 6'-4" as they'd have seating problems.

But isn't 6'-4" the exact height of another Irishman, one Serjeant Harper from the book of the superlative SHARPE series by that now-living-in-the USA author, Bernard Cornwell? ... a few, but only a few inches more than me but doubtless much much heavier!.

Every time I read about Sgt. Harper I think of Ted Mooney! Maybe Cornwall got that idea from you, eh?

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

Readers: if you don't care for the style of this forum, sorry -- but thanks for trying it.

If you do like it, please don't go away, we have thousands of pages like it --

but we badly need YOU to keep finishing.com "the most fun you can have in finishing".

Q, A, or Comment on THIS thread -or- Start a NEW Thread