-----

Rz to Ra conversion

Tall people, on average, weigh more than short people, so, to a limited degree, knowing people's height might help you estimate their weight (at least on a statistical basis) ... but you certainly can't "convert" their height to a weight.

The most important thing to realize about Ra, Rz, and other surface measurements is that they measure different things, just like height and weight do, so the word "conversion" is simply wrong! This is why the experts tell us to measure Rz if that's what you need to control, and to measure Ra if that's what you need to control, etc. -- because the best we can hope for is a rough "correlation", a reasonably safe estimate, not a conversion.

Further, when we try to 'correlate' in lieu of measuring, we must wastefully provide overly smooth surfaces because we must apply a safety factor in each direction. If you measured the Rz you might divide by 4-7 for an estimate of Ra (in the same units), but if you measured Ra you might multiply by 10-15 or more to estimate the Rz. Estimating rather than measuring is just not a good idea.

Current question and answers:

Q. May I know the DIN & ISO numbers which specifies about the conversion factors 7.2 & 7.6 which San mentions?

Ramkumar NatarajanEmployee - Chennai

October 22, 2021

⇩ Related postings, oldest first ⇩

Q. Could someone please help me out with a conversion factor. I need to convert Ra to Rz. If my print states a machined surface to be controlled to a maximum of Rz125, what would be the Ra equal? My measuring equipment has parameter settings of Rz.J, Rz.I and R3z. Which setting would I want if the characteristic tolerance is Rz125? Help! Please.

Todd D [surname deleted for privacy by Editor]- Toledo, Ohio

2000

A.

Rz (din) = Ra*7.2

Rz(ISO) = Ra*7.6

Ra=Rz(din)/7.2

Ra=Rz(ISO)/7.6

- shanghai china

April 8, 2008

Q. Convert Rz value to Ra.

Subramani MOHAN KUMARMACHINING - HOSUR, TAMIL NANU, India

January 18, 2009

Q. Please guide me how to convert Ra 2 to Rz?

B MohosinAutomotive - GURGAON, Haryana, India

March 10, 2018

A. Hi Mohosin. The best advice is don't! Just MEASURE the surface's Rz instead. Although you can convert meters to inches or pounds to kilograms, because they are both units of length, you can't convert inches to pounds or meters to kilograms. The best you can hope for is some degree of correlation. If I tell you that my sister is 62 inches tall, you cannot tell me her weight; the best you can say is something like "It's reasonably safe to believe that she weighs more than 70 pounds and not more than 200 pounds."

The problem here is that going from Ra to Rz or vice-versa is a 'rough correlation' not a 'conversion' because Ra and Rz don't measure the same thing. For correlations to be relatively safe depends on which direction you want to go...

If you know the Rz, you can divide by somewhere between 4 and 7 to estimate the Ra that you will be able to pass with reasonable safety.

But if you know the Ra, you should multiply by probably 15 to 20 to estimate the Rz value you will be able to pass.

In other words, you can estimate that the Rz of your part is probably about 30 or 40, but even with such a conservative estimate you may not be able to promise it :-(

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 5, 2018

A. Dear sir

As per the discussion of all that was found very good.

We can convert any value Like Ra to Rz which was already measured.

But the condition of measuring is very important.

Ex.: Ra means average of maximum and minimum.

Rz means points to be taken only peak values (maximum )

Measuring conditions are standardised and that should be followed.

Before measuring check whether given Ra / Rz value is in MM or Inches. Most of the confusion starts here only.

- Chennai,Tamilnadu, India

Q. How to convert Ra to Rz1max?

Shanath PANDIAN- Chennai, Tamilnadu, India

July 18, 2019

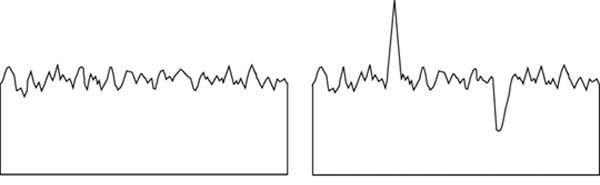

A. Hi cousin Shanath. When you use the word 'convert', despite what's written on this page (that a very, very rough correlation rather than a conversion is the best you can hope for) I get concerned that you may not have taken the time to understand what was explained here. You can try to estimate someone's weight by measuring their height but it is simply a bad idea to even try. Rz involves taking five measurements of maximum peak-to-valley, and Rz1max is the largest of those five measurements. This classic picture from

https://www.productionmachining.com/blog/post/the-difference-between-ra-and-rz

shows two surfaces with identical Ra but ludicrously different Rz (and Rz1max):

I note that some metal coatings like nickel plating will produce a beautiful mirror finish from the profile on the left, but will make the peak and valley on the right-hand profile "stick out like a sore thumb", which exemplifies why different measuring standards are used and important for different purposes. If you need to monitor Rz1max please start by realizing the need to measure Rz not Ra. Best of luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. What is difference between RaMax & Ra value, or can you provide comparison chart of above?

Rana Dny- Pune Maharashtra, India

May 3, 2021

A. Hi Rana. There can be no chart because because of what the word "Max" means, but your question is clearly answered at digitalmetrology.com/whats-with-the-max/

In brief and in summary, a limited number of Ra readings can sometimes exceed the specified value without the part necessarily failing the spec, but RaMax says none may. But please read and understand that page because in truth surface metrology requirements simply can't be summarized in a sentence -- since I don't work with it, every time a question comes in I have to spend half an hour refreshing my own memory. :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

May 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread