-----

Conductive Plating of Ceramic Cylinder (help and supplier needed)

2000

To any interested Supplier or Expert,

I am a R&D engineer for a small company that is developing micro-sensor systems for sensing pressures inside the body.

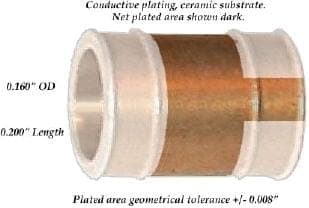

I need to coat ceramic cylinders that are 0.160" OD and 0.200" long with a conductive coating. There are several candidate ceramic materials to choose from that all have low coefficient of thermal expansion (CTE) as needed in this application. Some are porous, some are nonporous. All may be processed at high temp if need be.

We need to ultimately have only a circumferential strip (about 0.100" wide) on the OD to be conductive plus a small axially oriented strip that connects to the circumferential one.

I am considering the following processes although I don't know about the plating.

by Sha, Wu, & Keong

on eBay or Amazon

or AbeBooks

(affil link)

1. Electroless copper plate the entire parts.

2. Apply resist to the desired conductive areas.

3. Etch and then remove resist.

I need the conductive layer to be in the range of 100 micro inches

- to 1 mil and controllable in thickness to within ± 0.0002". We will be either soldering or conductively bonding to the surface. A supplemental coating of tin or other non-tarnishing material to the copper is desirable but not essential.

The quantities are about 100 for development, then batches of roughly 10,000-50,000.

Anyone interested, please comment on the following:

1. Recommended plating supplier (we can do the masking and etching elsewhere if the supplier is unable)

2. Does the electroless copper & etching scheme described above sound reasonable? Would selective plating be better? Would some other plating material be better?

3. Can this process (or another) be done to ceramic and if so should the ceramic be porous or nonporous?

Thanks in advance for your help.

- Los Angeles California

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q, A, or Comment on THIS thread -or- Start a NEW Thread