-----

How to make 0.1N sulfuric ACID

(to provide context, hopefully helping readers more quickly understand the Q&A's)

A 'molar solution' or '1.0 M' solution is defined as a solution which contains one gram-equivalent weight of the substance in question dissolved in 1 liter of solution (the water).

The atomic weight of a molecule of sulfuric acid, H2SO4, would be the atomic weight of 2 atoms of H plus 1 atom of S plus four atoms of O (the atomic weights can be obtained from the Periodic Table, or an appendix in the Metal Finishing Guidebook) as

2*1.008 + 32.066 + 4*16.000 ... or 98.082

-- let's round it to 98.

So a 1.0 M solution of sulfuric acid contains 98 grams of sulfuric acid per liter of water. Working with different strengths like 0.5 M (1/2 molar or 49 g/L) and different volumes is then a matter of simple arithmetic.

Since two protons [hydrogen atoms] are available to react in sulfuric acid, the normality of sulfuric acid is always twice its molarity, a 1.0M solution is a 2.0N solution.

Q. Are you able to make 0.1N sulfuric acid from 50% sulfuric ACID? What would be the proper amount of D.I. to make this happen?

BLH HanshawLAB TECH - Chandler, Arizona

October 13, 2021

A. Hi BLH. Yes, you can do this but if you could set the stage by telling us why you want to do it, the answer might be better. For example, usually when something is expressed as a low normality solution like that it's because it will be used in analytical work, and you don't want to be making a test tube size batch of 0.1N sulfuric acid from 50% sulfuric acid for an analytical titration, you want to buy lab chemicals :-)

As you see from the tutorial, a 0.1N solution of sulfuric acid is the same as a 0.05M solution, so it would have 5% of 98, or 4.9 grams per liter of acid. You would want to put the better part of one-liter of D.I. water in a large flask, then add 9.8 grams of your H2SO4 (because its 50%), and then add the remaining D.I. to fill the flask to the 1 liter mark.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 2021

(affil links)

free pdf is currently available from academia.edu

![]() Thank you for getting back to me sir. The solution will be used for analytical testing. The reason I am seeking out the proper way to make the solution is because the wait time is too long for a bottle to arrive. Our vendor will not be able to have it delivered until 2nd week of DECEMBER. We cannot wait that long.

Thank you for getting back to me sir. The solution will be used for analytical testing. The reason I am seeking out the proper way to make the solution is because the wait time is too long for a bottle to arrive. Our vendor will not be able to have it delivered until 2nd week of DECEMBER. We cannot wait that long.

So in the meantime I am trying to find alternative solutions -- no pun intended.

LAB TECH - Chandler, Arizona

October 14, 2021

A. Good luck. Hopefully a reader will double check my numbers as I am not a chemist :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

October 2021

December 28, 2021

A. If you are running in an accredited shop you need to quickly write an SOP allowing use of homemade titrants from certified stock, using class A glassware, and calibrated measuring devices (pipets, balances, whatever).

The most accurate dilutions are always those made in large volumes. Get a 1L flask of the sort with a giant bulbous base and tall skinny neck with a volume band etched in. Test the conductivity of your dilution water and record it as part of your self-certification SOP. Make sure it conforms to ASTM lab water standards, under 5 µS/cm. Log and file it as you would with incoming chemical certs. You may end up arguing with an auditor but walk away clean if the documentation is correct and your SOP is written well.

As for the calculations... there are a lot of online resources to help because this is a standard question on high school chemistry exams.

Example:

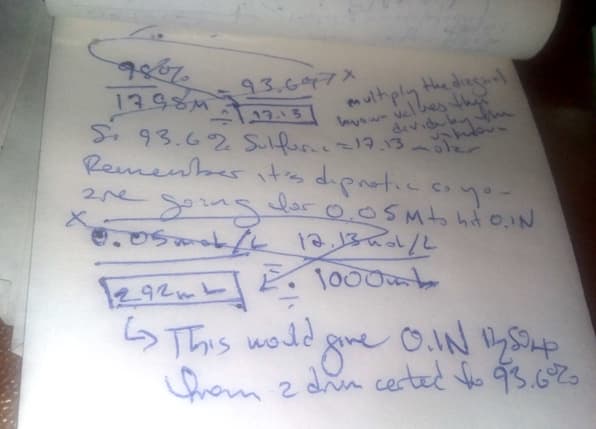

If you have a drum of 94% sulfuric certified as 93.6, look up its molarity and normality. Yes there are online calculators :) but good luck with those... if 98% is 17.98M and 95% is 17.8%, you can do a calculation like so:

(See pics) and check your accuracy using the same calculation for the other known value to ensure your interpolation is correct.

It's a diprotic acid so keep that in mind. Molarity (moles per L) and normality (basically, active moles per L) are not the same. Figure out the exact NORMALITY of your stock. Apply a dilution factor that will bring you where you need to be.

By my calculations shown, you would need 2.92 mL of 93.6% drum stock in 1000mL of DI water to make this titrant. Use this method adapted for what your drum cert says. And as a lifelong analytical tech... there's more nuance to making good reagents than I care to get into here, because I'm tired and my thumb hurts.

Always back-titrate it against a known certified reagent before use; any anodizing shop will have 1.0N NaOH [1N NaOH on

Amazon [affil link]

and id use double the sample size (at least) and some math to verify accurare dilution since it's so weak compared to a tank, so the error increases. Document both lot numbers plus the back titration, and be prepared to prove your math.

You will probably need to invest in some high end pipets if you're going to pull this off.

And you need to scold your Purchaser/inventory person with regards as to why you ran out to begin with. I'm having sourcing issues with one specific conductivity standard lately but it's admittedly a bit obscure (10uS as NaCl, and I'll only accept Ricca lots not sold in freaking pouches). But forgive my bending of site rules here- Grainger Industrial Supply is a decent fallback and easier than math. You'll spend less time on the phone, and less money on the company card, finding something with a cert that can be expedited.

Lab Rat and some other things - Greenfield

December 31, 2021

A. If I could add a little to Rachael's answer.

The most important point is calibrating your solution.

98% sulfuric acid absorbs moisture rapidly so whatever it was originally certified does not last and no auditor would accept simply diluting it as acceptable. It must be calibrated against analytical grade (and dried) sodium carbonate but standard sodium hydroxide may be acceptable as a short term measure although that also deteriorates by absorbing carbon dioxide - the burette should have a trap if you want to impress an auditor !

I would never insist on grade A glassware in a finishing shop lab. Within the accuracy needed for plating solutions, accepting all the other variables, B grade is sufficient; and a lot cheaper. A grade is for research labs.

Geoff Smith

Hampshire, England

Q, A, or Comment on THIS thread -or- Start a NEW Thread