-----

Gold Tone Finish for Aluminum

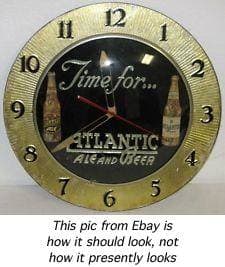

Q. I am restoring a 1940s advertising clock whose outer edge was originally a gold tone. The clock is made from a thin stamped piece of aluminum that has been painted and decorated with paper pictures of the product glued to the surface. The thin round aluminum sheet is mounted a piece of fiberboard. The clock is approximately 20 inches in diameter and the gold tone edge is approximately 1 -1/2 inches wide and contains raised painted numbers. The gold tone has faded away over the years and only remains on a small portion of the surface that was covered be the bezel ring. The gold tone inscription that was under the glass is still bright.

I would like to restore the clock to its original appearance. I'm guessing the original was an anodized finish. I have investigated using a chem-film finish like Alodine 1201

⇦ on

eBay

or

Amazon [affil link] and then covering it with a clear lacquer. I could do this but I'm a little concerned about doing it in a home environment. I don't really need a finish for harsh environments I would just like to re-create the original glossy gold tone finish.

Does anyone have suggestions on to best achieve the desired look?

Hobbyist - Lutherville, Maryland, USA

August 29, 2012

A. Hi Michael. There are paints made for this purpose. They are not perfect, but they're not bad -- and they're very practical. Anodizing or Alodining that old clock would be a big job with a good amount of dangerous chemicals and required expertise.

See letter 26417, "True gold anodizing spray paint?"

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August , 2012

Q, A, or Comment on THIS thread -or- Start a NEW Thread