-----

Cadmium Cyanide Plating Bath Maintenance & Analysis

Cadmium presents toxic biocumulative effects much like lead and mercury, so there have long been intensive efforts to get it out of the environment, and some places do not allow it. Nonetheless, cadmium plating offers a combination of engineering properties which no other materials has (corrosion resistance, cathodic protection, freedom from bulky & gummy corrosion products, compatibility with saltwater, malleability, galvanic compatibility with aluminum, ability to plate onto carbon-rich substrates with good covering power, etc.)

So there are still some critical legacy applications where substitutes are not possible.

Q. Hello,

I have a cad plate supplier that outsources solution analysis on a monthly basis.

The tank solution range is as follows:

Cadmium Oxide: 3.0 - 4.5 oz/gal

actual = 3.5 oz/gal [26.3 g/l]

Sodium Hydroxide: 1.5 - 3.4 oz/gal

actual = 0.9 oz/gal [6.8 g/l]

Sodium cyanide: 13.5 - 16.4 oz/gal

actual = 11.6 oz/gal [87 g/l], and

Sodium Carbonate: 8 oz/gal max.

actual = 9.6 oz/gal [72 g/l]

Their regular practice is monthly testing, then make corrections / additions accordingly.

I could not find any limitations in AMS-QQ-P-416 or other industry standards.

Part of the monthly conformance testing is to also test corrosion 200-hour salt spray, hydrogen embrittlement test, adhesion and appearance.

All of these tests show conforming results.

Based on the solution analysis outside of their internal control range, should the supplier be checking more frequently and making the adjustments? Finally, with the solution analysis out of range, is there risk to product?

Quality engineer - ORANGE, California

April 18, 2025

Ed. note: We appended your inquiry to a thread where you can compare these values to those of other shops.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. We are currently running a cyanide bath cad plating line, and have been having trouble keeping our solution parameters in spec. We recently started precipitating out sodium carbonates (as they were creeping above 60 g/L) by cooling buckets of the solution to around 1 - 2° C. Once we began doing this, we found that it became very difficult to maintain our cadmium oxide levels (getting down around 19 or 20 g/L). Presently, we do not agitate or filter the solution (we stir it thoroughly prior to plating or taking bath samples), but will be purchasing a pump in the near future to perform both of these functions.

I was told by a reputable source that cadmium oxide shouldn't be added to the tank unless making up a new solution, and that the anodes should provide the supply of cadmium ions necessary to balance the tank. I have since seen several other specs (as well as postings here) that recommend adding cadmium oxide when the levels get low.

Is the fix as easy as adding the cadmium oxide? Is this what we need to do to maintain our solution parameters on a regular basis? So far, when the cad levels drop, we have been plating sheet stock until our levels come back, then beginning production again. We recently changed out our anodes, with the concern that the older ones had become passive.

Our solution specifications are:

Cadmium Oxide = 21 - 42 g/L

Sodium Cyanide = 87 - 150 g/L

Sodium Carbonate = 15 - 59 g/L

NaCN / Cd = 2.8 - 6.0

Our tank temperature sits around 75° F (24° C). Should we operate it at a higher temp? ASM seems to recommend 80 - 85° F. Should we also measure sodium hydroxide?

Any other pieces of advice for improved operation of this process would also be greatly appreciated.

Thanks in advance,

Manufacturing Engineer - Sidney, BC, Canada

June 14, 2011

A. Hi Nathan,

When I was involved with cadmium plating it was normal practice to add cadmium oxide if the cadmium levels were low. We would also look at the anode configuration if the cadmium content continued to fall and the anode area increased as necessary to try and maintain the cadmium levels without having to make additions. When you add the cadmium oxide it will have more of an effect than you expect as your free cyanide will drop and you sodium hydroxide will increase. It takes some playing with to get the balance right, but a couple of good books such as the Canning Handbook [on

eBay,

Amazon,

AbeBooks affil links] or the Electroplating Engineering Handbook ⇦ this on

eBay,

AbeBooks, or

Amazon [affil link]

contain some good advice.

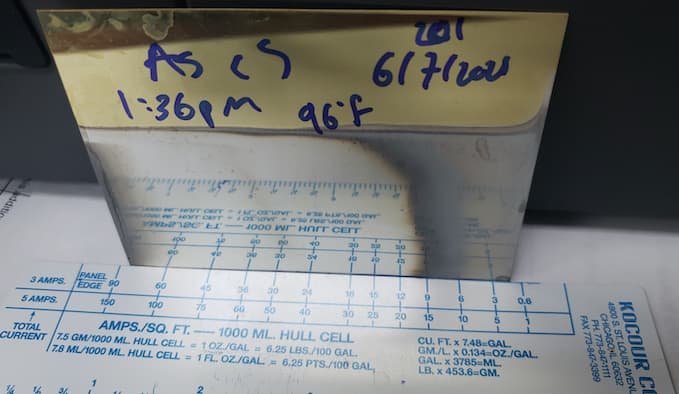

We always monitored the sodium hydroxide as well. We also did Hull Cell

⇦ huh?

s when there was suspect quality in the plating that couldn't be traced to any of the cleaning operations (a good quality control test).

Aerospace - Yeovil, Somerset, UK

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Hello,

We have a cadmium cyanide plating bath and I was hoping someone could help clarify my understanding of the solution analysis for cadmium metal.

Our process:

We take an aliquot and add the following:

pH buffer 10 consisting of ammonium hydroxide, ammonium chloride, and water (~ 10 mL)

10% formaldehyde (~ 15 mL)

and Erichromte Black T

We then titrate with EDTA.

I have three questions:

1) What is the purpose of the pH buffer (or really the addition of the ammonium hydroxide)? Is it to help drive a reaction?

2) Can someone confirm that the formaldehyde is there to liberate the cadmium-cyanide complexes freeing the cadmium for the titration?

3) In the books I have been reading, some recommend adding a few drops of 25% HCl prior to adding the ammonium hydroxide, is this step necessary and if so, what is its purpose if the next step is to add a few mL of a alkaline liquid?

Thank you all in advance.

- Denver, Colorado, USA

February 29, 2012

A. I must say that whenever adding acid to a cyanide solution you are analyzing, it MUST be done in a fume hood. Deadly Hydrocyanic Acid is liberated.

I used to use premixed 1:1 sulfuric acid dropwise until the aliquot just turned milky.

Ammonia/Ammonium Chloride buffer is added to make it alkaline.

Indicator used is eriochrome black t

⇦ on

eBay or

Amazon [affil link]

. (Mixed at 1 Gram of dye to 99 Grams Reagent NaCl. Correct amount of dye is a learned skill. Too much; and the color is too dark to see the endpoint. Too little; and the color might fade.

After the dye is added, and JUST before titrating, add about 10 ml. of 1:9 Formaldehyde. Titrate immediately. Titration times the "factor" will give oz/gallon of Cadmium. When you get to the endpoint, add 5 ml. more of formaldehyde. If it reddens, continue the titration to a Blue endpoint. Note that the endpoint may turn red in a minute or so. You have reached the endpoint, and use that for your calculation.

(affil links)

free pdf is currently available from academia.edu

Why do we use 0.0575 Molar E.D.T.A. in plating? Long ago, a man named R.O.Hull noted that when analyzing zinc, that this Molarity gave a factor of 1. Other factors may be calculated. The Metal Finishing Guidebook ⇨

might be a good source of the correct factor to use for your analysis.

Remember: Safety first. You are analyzing a cyanide solution, and all care must be used. I've done thousands of these cadmium titrations, and must say that you will develop the skill to "know," how the color will change. Some baths that are high in iron contamination will act differently and you need to know the individual characteristics. Practice and hone your skills.

Ed Budman [deceased]

- Pennsylvania

With deep sadness we advise that our good friend Ed passed away Nov. 24, 2018

Q. I'm having trouble with the sodium hydroxide level (too high) and sodium carbonate level (too high) in my cyanide cadmium plating tanks (barrel and tank). The specification for NaOH is 1.6 - 4.0 oz/gal for both (result is 5.1 for tank and 6.6 for barrel). The specification for Na2CO3 is <8.0 oz/gal result is 11.0 oz/gal for tank and 10.9 oz/gal for barrel) I've tried chemical removal using calcium hydrated lime which did nothing but increase NaOH. Freezing is not an option.Tank sizes are about 2500 gallons for tank and 175 gallons for drum.

Please help if you can.

- Birmingham, Alabama, USA

June 13, 2013

Q. I posted earlier, but entered incorrect data. I'm having trouble with high NaOH in both baths (5.1 oz/gal in 2500 gallon tank and 6.6 oz/gal in 175 gallon tank - range is 1.6 - 4.0 oz/gal), low pH in both baths (11.7 in 2500 gallon tank and 11.6 in 175 gallon tank - range is 12 - 14), and high Na2CO3 in both baths (11.0 oz/gal in 2500 gallon tank and 10.9 oz/gal in 175 gallon tank - range is <8.0 oz/gal). I've tried to precipitate Na2CO3 out using calcium hydrated lime which only increased the NaOH. Freezing out isn't an option.

Please help if you can.

- Birmingham, Alabama, USA

Q. I have an aerospace plating spec that lists as a makeup for our cyanide cadmium plating bath the following:

Chemical

|

Initial conc. oz/gal

|

Oper. range oz/gal

|

Is just "Sodium Cyanide" the same as "Total Sodium Cyanide""?

and is "total Sodium Cyanide" the same as just "Total Cyanide"? Our cust. spec seems to differentiate as shown in the list above but I can't seem to get answers from labs whether I can test for all that's listed. Your help would be greatly appreciated.

Thanks

Sherrill Connell- Monroe, North Carolina, USA

July 29, 2013

A. With Cd it doesn't make a lot of difference. The complex that it forms with CN- is quite weak and you're pretty much titrating it all.

Dave Wichern

Consultant - The Bronx, New York

Q. Hello, I am quite new to the electroplating industry and have been hired on as my company's chemist. Unfortunately there was no one in the position before I entered the scene and I am woefully uninformed on nearly all the analyses which need completed to ensure proper functioning of our process tanks. My current headache is my Cadmium metal content in our Cad / Cyanide plating tank. The only procedures which I have to follow or go on are several older metal finishing books and what I can glean from sites online such as this. That being said the current procedure I am attempting to follow is that spelled out in the metal finishing guidebook for Cad metal content analysis.

It goes as such:

Add 2 ml sample from Cad tank

Add 100 ml DI water

Add 10 ml pH 10 buffer

Add EBT powder

Add 15 ml 10% Formaldehyde

Titrate with 0.1M EDTA

Color change of Red to Blue

I am having significant problems. The first being recognizing the endpoint. From what I have researched online the color of EBT in an alkaline solution complexed with "metal" ions should be somewhat of a "wine red." After following the above outlined procedure and adding the EBT I am NOT getting any sort of red color, more of a purple that seems to be what I have seen as the color of the EBT as it nears an endpoint. In an effort to determine the endpoint more exactly I took a flask of tap water, added a small amount of of EBT / NaCl mixture (1/100) and a small amount of my pH 10 buffer and to my delight began to see the red color I was supposed to. I wanted it a bit darker and proceeded to add a bit more EBT mix and splashed in a significant amount of pH 10 buffer and to my dismay the solution turned a deep purple blue. This confounded me. The pH 10 buffer I have is 0.38% Sodium tetraborate, 0.05% NaOH, and 99.57% water.

I am now here asking for any help that anyone may be able to offer. I have no other resources available, no procedures to follow, no one to ask. We do not run our Cad with brighteners, and I have very little information on the bath other than its current pH. (13.2) If I can determine Cad metal, I can determine total CN- and then free.

Again any help would be more than appreciated, or any resources anyone could point me towards would be fantastic.

Thank you in advance.

plating shop - Huntington, West Virginia USA

November 21, 2017

A. Hi Jordan

Welcome to the frustrations of EDTA titrations.

A full answer is not practical here but there are several alternatives. These partly depend on what kit you have available; do you, for instance, have a fume cupboard to drive off the cyanide? (and incidentally do you know about cyanide first aid etc?)

by Langford & Parker

on Amazon

or AbeBooks

(affil link)

Long term, you should try to get hold of a copy of "Analysis of Electroplating and Related Solutions" By Langford and Parker ⇨

a rather old book but sound. You can download a pdf copy (at some cost)

http://jes.ecsdl.org/content/106/6/151C.abstract ⇩

Longer term you might try to get hold of Atomic Absorption

⇦ on

eBay

or

Amazon [affil link] kit. You will not need the latest bells and whistles so an old second hand unit might be cheap.

Your quickest way to get help is to contact your chemical supplier. You will find them very helpful and anxious to ensure that their processes are well maintained. Most have standard analysis methods for their products.

If you are new to cyanide plating, this may help

https://www.academia.edu/10635761/Cyanides_in_Metal_Finishing_Risks_and_Alternatives

If you are new to plating, there is much to learn. You may consider the distance learning courses offered by e.g.,

https://www.materialsfinishing.org/

Geoff Smith

Hampshire, England

Ed. update: Sorry, jes.ecsdl.org no longer offers "Analysis of Electroplating and Related Solutions"

Geoff's other links have been updated to https (secure/encrypted)

Q. Geoff, thanks for the response. I will attempt to answer your queries in the order which you dispensed them.

by Terrance H Irvine

on eBay or Amazon

or AbeBooks

(affil link)

I have a copy of The Chemical Analysis of Electroplating Solutions by T.H. Irvine ⇨

although it is somewhat dated and preaches a sulfide method for metal determination.

I will have to look into an Atomic Absorption Kit.

As far as contacting my chemical supplier I would say that is an excellent idea, however, our Cad tank is run without brighteners, off a metal finishing handbook "recipe" which I have inherited and as such has no technical data associated with it. I guess there is nothing to lose in asking, although I have run into some issues with companies being wary of cyanide baths.

I will look into your additional links and hopefully they may give me some additional direction.

If I may place another question, what is the use of the 10% formaldehyde in the titration and would a different buffer solution provide better results? As I mentioned, I have yet to achieve the "wine red" color associated with complexed EBT in an alkaline solution and am attempting to fully understand the mechanisms by which everything is taking place.

Again, thank you for your quick reply and sources, glad to hear I am not the only person that experiences issues with compleximetric titrations.

Regards Jordan Egnatoff [returning]

plating shop - Huntington, West Virginia USA

Q. I do not see an answer to the situation addressing how to reduce a high NaOH concentration exceeding the control limits. I have inherited a new LHE Cadmium solution make up that did not fully take into consideration of the increase from the cadmium Oxide. This is an Aerospace company with Boeing and Safron specification requirements. Besides decant, is there a treatment to reduce the NaOH concentration in an LHE cadmium solution.

Thank you.

Landing Gear Overhaul - Longwon, China

March 22, 2018

Q. Can I know what is the reference document for cadmium plating (titration method)?

Nor Elly- JOHOR, MALAYSIA

December 14, 2018

A. Hi Nor. I don't do titration nor maintain reference texts about it in my library, but on this page and on many other occasions both the Langford & Parker [on AbeBooks or eBay or Amazon affil links] and the T. H. Irvine ⇦[this on Amazon or eBay or AbeBooks affil links] texts have been suggested. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Hi Nor, after several months, I have managed to get my cad cyanide titrations down pat. What specifically are you interested in determining? Cad metal was my biggest headache, but with the right buffer (and timing) I can get reproducible results every time which are within less than 5% of what my outside lab tested by ICP. Cyanide is a cinch and OH- content is best done with a pH meter instead of sulfo-orange ⇦ on eBay or Amazon [affil link] . Let us know what you require.

Jordan Egnatoff [returning]plating shop - Huntington, West Virginia, USA

Q. Hi,

Currently I have troubles with the conductivity for my cadmium cyanide tanks, we established optimal parameters but it was in February. In February the weather is too cold here in Nogales, and we started to get troubles when we notice that the tank temperatures started to get high and we do not have currently chiller equipment.

I've tried to go High with different parameters like Sodium Cyanide, Sodium Hydroxide, brightener, Cad oxide and wetting agents, but we cannot get good results yet.

These are our parameters before the temperature getting up.

Cad metal (Oz/Gal)= 3.0

NaCN (Oz/Gal)= 15.0

NaOH (Oz/Gal)= 3.0

Ratio (NaCN/Cd)= 5.0

Temperature= 75 °F (70 °F-82 °F)

And our current temperature is 95 °F-115°F. I hope that you can advise us.

- Nogales, Mexico

June 7, 2021

A. You must cool it down to 75 °F and that will clear the high. Add CN to 18 and that will clear the low.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

![]() Thank you Robert H Probert!!

Thank you Robert H Probert!!

Yes, actually I've cooled down the cad from 105 °F to 87-91 ° F and with cyanide additions (from 15 Oz/gal moved to 17-18 oz/gal) I got good results.

- Nogales, Sonora

Readers may also be interested in this related thread:

• Topic #83/59 "Spec QQ-P-416 and AMS-QQ-P-416?"

Q, A, or Comment on THIS thread -or- Start a NEW Thread