-----

Valve Body Deburring

Q. I am currently working to remove burrs from valve bodies. We use strictly manual methods right now and are looking to automate this process. The burrs occur in intersecting holes and one hole only partially breaks into another leaving part of the hole remaining. This has prevented me from using deburr tools. I also have a problem with pipe threads in one hole and an orifice which if nicked causes the part to be scrap. Is there a fast deburring method out there that can remove burrs in hard to reach places without damaging delicate areas.

Patrick Rogers- Bristol, Connecticut USA

2000

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Pat There are 2 possibilities, but because of the threads, I suggest you check out a system for thermal deburring. This is a controlled explosion in microseconds that has tremendous heat that will remove burrs especially good on I.D.'s. and threads. There are a number of valve manufacturers using this type of equipment in this area.

AF Kenton

retired business owner - Hatboro, Pennsylvania

2000

Q. I saw your response on thermal deburring. I understand that is effective on aluminum, but we are making a lot of valve bodies out of 316 cold worked stainless. Do you know of any options other than hand deburring for this type material?

M Steffen- Cincinnati, Ohio

July 28, 2011

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

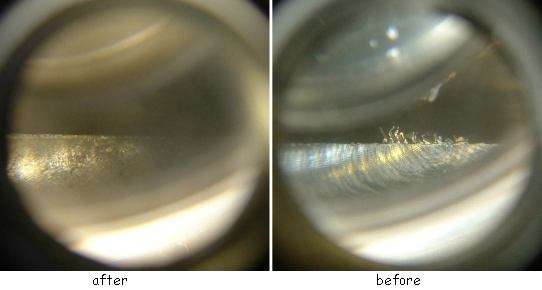

A. We specialise in thermally deburring manifolds in steel, aluminium and stainless 316. We get excellent results.

Although the explosive deburring removes less material with 316 than with aluminium or steel, the milled burrs tend to be smaller and finer. So better to oxidise.

If too much heat is put in (for bigger burrs) you can start to get discolouring like the bluing from welded joints.

Martin Bridges- Poole, Dorset, UK

November 29, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread