-----

Silvering formulas using silver nitrate

[editor appended this entry to this thread which already addresses it in lieu of spawning a duplicative thread]

Q. Hi It has been a while since I was in this site. I have been trying to find the formula for silvering solution. Can anyone please help me to drop the link to it?

I am pretty sure there is a use of sucrose somewhere in the processing ... as I got at the moment is using

Silver Nitrate solution with caustic soda with ammonia and distilled water.

And yes I am kind off loss after these steps.

- Jakarta Indonesia

March 2, 2024

A. Hi Selwyn.

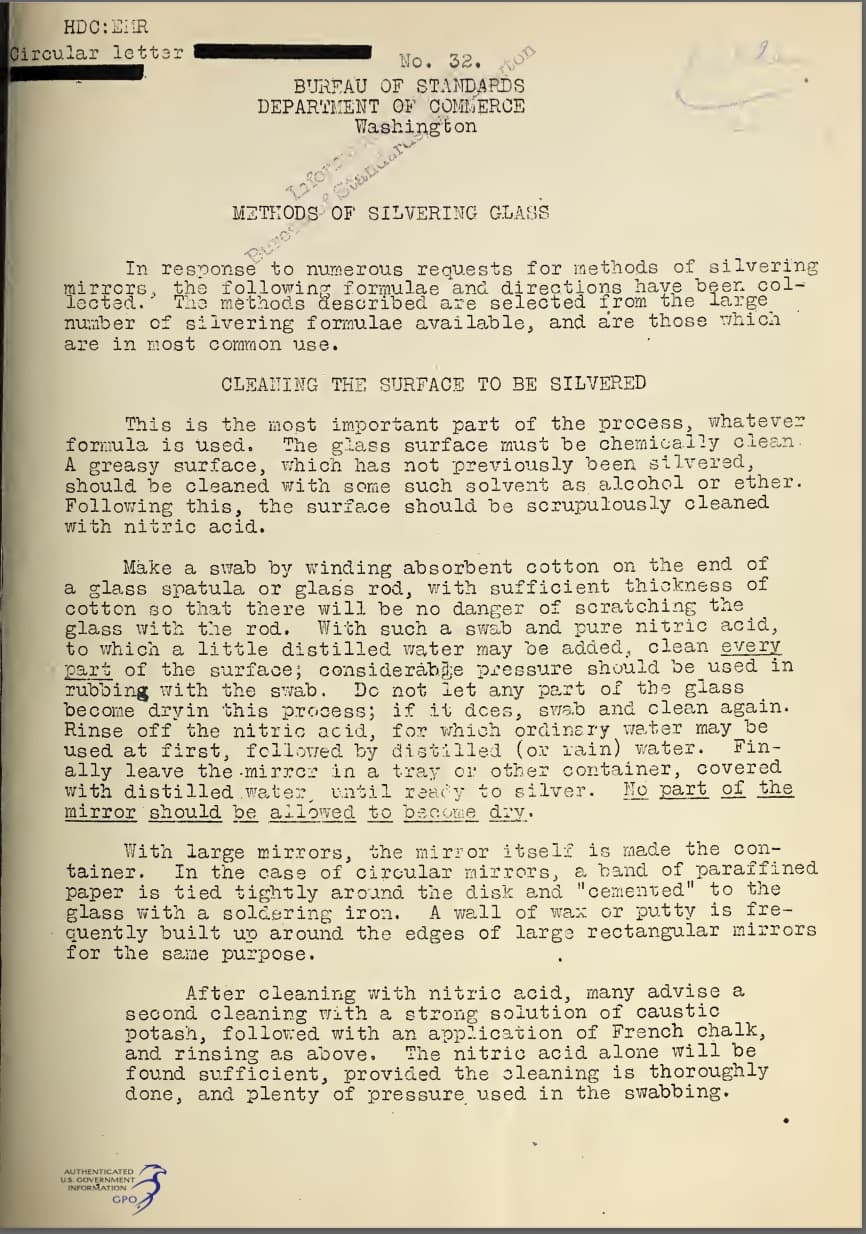

Mirror silvering was invented/developed in 1835, nearly 190 years ago, so naturally there have been dozens if not hundreds of alternate methods and proposed improvements, so asking for "the formula" will be an open and contested question. You can see this 100+ year old circular from the Bureau of Standards for the many methods already offered by 1919 ⇨

We've appended your inquiry to a thread which includes a lot of information, and you can also search the site for a half dozen other threads on 'silvering'. Or google for "Brashear process".

Note that the best formulas may depend on what you are attempting to metallize and why. What may be an ideal formulation for applying silvering to glass for use as a mirror may not be the ideal formula for 'spray chrome' on plastic. But please read the rest of this thread and its warning about experimenting with silver compounds.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇩ Related postings, oldest first ⇩

Q. After using a silvering solution from Peacock Labs has anyone tried to make their own chemical? If so what success did you have.

Dean Smithowner - UK

2007

Ed. note: Readers are encouraged to answer by referring to books or published articles. Sorry, we can't print formulations except those offered by readers well known to us because we must be careful to avoid crowdsourcing the theft of Peacock Labs (or other suppliers) trade secrets :-)

For safety sake we also warn that people carefully investigate the concept of explosive "silver fulminates" before mixing anything with silver chemicals!

A. Dean,

Old texts contain many formulations for silvering solutions.

I cannot recommend any. You exchange a known and acceptable problem (cost) for an unknown process involving a significant possibility of accidentally generating explosive silver compounds. Many of the recommended reducing agents like hydrazine are also difficult to justify in today's safety culture.

Geoff Smith

Hampshire, England

A. A very old recipe I came across did the following:

1) prepare a buffer solution of 200 g sodium hydroxide and 150 0.88 ammonia

⇦ on

eBay or

Amazon [affil link] solution in 1 litre of water.

2) Mix 90 mls 0.88 ammonia and 35 g of silver nitrate with 1 litre of water and add 70 mls of the buffer solution. Dilute this with 1 litre of water. This is the spraying solution for silver;

3)Dissolve 150 g of glucose in 1 litre of water and add 140 mls of formaldehyde. This is the reducer and should be diluted to 65 ml/litre with water when sprayed.

This is a very good two-part silver spray solution that gives a bright shiny deposit. However, many substrates need to be sensitised before the silver will adhere to it, especially if it is a plastic, so the correct activation process is needed.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

Ed. note: This forum has numerous threads about silvering, but topic 23536 specifically covers the sensitizing issue that Trevor mentions.

Silvering inside a bottle

Q. I wonder if someone could tell me the best solution for silvering the inside of a bottle. I remember at a thermos factory, 2 solutions being mixed together and then swilled around the inside of a bottle.

The result was a wonderful silver mirror finish.

If someone could help, I would be very happy?

gilder and designer - London, UK

March 21, 2009

A. I found a answer on Google by searching "silvering the inside of a bottle".

I think I should post this as I have been looking for this information for quite a while, see:

www.terrificscience.org/freeresources/presentations/pdfs/silvering_with_note.pdf ⇩

This is a copy of a textbook from 1990. Good luck, J

- Harwood, Maryland, USA

June 9, 2009

Ed. note: Unfortunately that link is broken and archive.org did not archive it.

How to Silver a convex mirror

Q. I tried to make a convex mirror but something is not working.

I have a description for flat mirrors where it said to keep 2 mixed solution on the surface of glass for 30 minutes, but on convex glass I can't do that.

Can somebody give me an advice?

hobby - Brampton, ON, Canada

April 13, 2009

A. Hi, Virgil. The cost to do it the way industry does it may be cost prohibitive, but I think the way it would be done would be to mount the mirror on a spin table, and spray it with 2-part silvering solution, allowing the excess to run off for re-use and eventual treatment. I haven't actually seen convex mirrors done that way, but I have seen similar products like vinyl masters for recordings done that way. Maybe a children's spin paint machine with a wetted sponge will do it, or just a wetted shammy big enough to cover the mirror.

But if you really want 30 minutes exposure rather than a few seconds, why not put the mirror in a container with enough soution to cover it? Good luck.Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Fire chrome/plasma chrome/flame chrome

Q. Hi all. I found a youtube video regarding a fire chrome. Some says flame/plasma chrome. I'm not much of a chemist but it looks like a simple process. The chrome activates when you flame treat it.

I'm a metal hand engraver by profession and I would like to have a chrome finishing look on my product. Based on my research, I assumed silver nitrate would be the main ingredient. Appreciate if some would assist me on this.

Hobbyist - kuala lumpur, malaysia

March 24, 2020

A. Hi Sham. Yes, it's probably silver nitrate or a similar compound where silver ions are dissolved; and apparently flame is used as the oxidizing agent or one of the oxidizing agents. You should speak to the vendor about it's applicability to metal surfaces, and about buying it or licensing the technology. We're happy to continue to post references to published literature, and replies from people well known to us, but we can't crowd-source info on how to duplicate a proprietary product -- there's no way for us to know the legitimacy of an anonymous poster's knowledge; they could even be a disgruntled employee such that we'd be crowd-sourcing industrial espionage :-)

Good luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I am trying to find flame chrome/fire chrome/plasma chrome.

I just watched youtube video of flame chrome.

We want chemical formulation of flame chrome?

How to apply ?

- MUMBAI INDIA

May 12, 2021

A. Hi cousin Darshan. 'Open source' can be a good idea, we're all for sharing here :-)

And if anyone can offer published references on the subject, we're happy to post them! But as we've explained on this thread before, we can't post info on how to duplicate proprietary products! There's no practical way to know whether a poster is offering knowledge they developed themselves, or whether we'd be participating in crowd sourcing of theft of trade secrets :-(

But there are some general hints on the page :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread