-----

Misplating on Zinc and Nickel-Chrome Parts

Q. We are trying to plate parts with Zinc or Nickel chrome. After plating we see a white line of misplating on parts. On analysis by SCM [scanning capacitance microscopy] it shows carbon. From where is it coming and how to avoid this.

Any answer to this?

Electroplater - Toronto, Ontario, Canada

2006

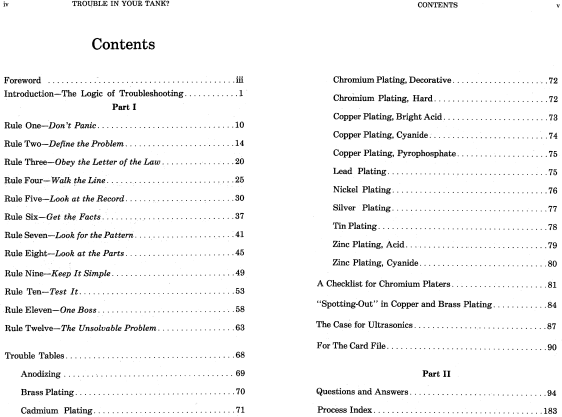

A. Hi Sunil. Please observe that Larry Durney's famous "Trouble in Your Tank?" doesn't even mention microscopic examination: .

Likewise, rightly or wrongly, I've always strongly believed that the truism "you can't see the forest for the trees" applies to attempts to use elemental analysis equipment to troubleshoot plating problems -- and that you usually can't determine much by looking at the parts, without studying the process sequence and walking the plating line.

But if you can, please send us pictures of the parts, and some details like what the substrate is, whether you rack or barrel plate, and what the process sequence is, whether the defect occurs on the top row of parts, bottom row, or all rows . . . and maybe we can help you decide what to try to look for. I find it strange that zinc plated parts and nickel-chrome plated exhibit the same defects. But I did once see an installation where a defect in the electrocleaning tank design caused high current and consequent dezincification "along a line" in brass parts. Best of luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2006

Q, A, or Comment on THIS thread -or- Start a NEW Thread