-----

Nickel Plating defect: white patches

Q. Hi. I am facing an issue in nickel electroplating on Aluminium part, where white spots are observed on surface after a week. we have tried using surfactants to avoid hydrogen embrittlement. I hope you might help us with this. What could be the possible root cause of this problem and what could be solution to that?

Naman Savaliamanufacturer - Jamnagar [India]

April 24, 2025

A. Hi Naman,

I think you may need to retain an experienced electroplating consultant to help you with this one.

Did you mean "hydrogen embrittlement" or was that a mistake? It's rarely a problem in aluminum except high strength aluminum in special applications, and surfactants would be unlikely to reduce it ... so I suspect you meant to say "hydrogen pits"?

You could probably take a few finished parts, scrub them with a brush and detergent, then carefully rinse them in DI water and set them aside for a week to get a sense of whether the problem is some addition agent left on the parts or some contaminant in the final rinse rather than a problem earlier in the process sequence.

If that doesn't fix it, we have no idea what kind of parts, what alloy, whether you are barrel plating or rack plating, what pretreatment you are doing, whether you are plating the nickel directly on the zincate or on an intermediate layer, what type of nickel plating you are doing, any of the plating parameters, what this defect looks like, how often it occurs, on what area of the parts, etc. -- so we'll need a lot more information. 🙂

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

⇩ Related postings, oldest first ⇩

Q. Dear sir,

currently my company is running the nickel plating 1700. I would like to know what is the root causes of the visible white patches occurring during the plating process.

Thanks and have a nice day .

Charlene Tanmetal stamping - Malaysia

2006

A. Hi Charlene,

There are a few things that could be causing this type of stain. Make sure the chloride level in the bath is within range. The stain could also stem from organic contamination. Try a few carbon packs - 2 hrs per carbon filter with the bath at operating temp. Add back any organic additives per the tech data sheet for the bath. Make sure rinsing is adequate. Good Luck!

Process Engineer - Syracuse, New York

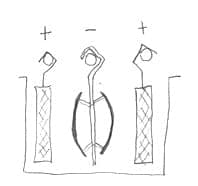

A. Like Mark's saying, very high chance it's due to organic contamination in nickel bath. You can run a Hull Cell ⇦ huh? test to see if similar white patches appear on hull cell panel after plating. If so, do a carbon treatment (add in 2 g/l activated carbon powder and maintain at ~50 °C with circulation for 1 hour) of same sample and re-run hull cell again and if such white patches disappear then confirm the problem is due to organic contamination and you can make a decision to do carbon treatment online.

David Shiu

- Singapore

Ed. note: This is one of dozens of threads about defects in nickel plating. For additional insights, Please search the site with as exact description of the defects as possible.

Q. Hi sir, I'm in chrome plating company. I'm facing white patches after bright nickel plating. As per observation I observed that there is poor plating in back side of all parts. Completely black after semi-bright.

What can be done for this? Please seniors assist me.

- Bangalore, INDIA

August 7, 2018

A. Hi Chandrashekhar. You posted a similar problem four years ago. Did that thread help at all? Again, if you forward some pics we will have a better understanding what you are talking about. I'm not certain what you mean by "poor plating in back side" but if the 'back side' is shaded you shouldn't expect good plating there. Truck bumpers have been racked back to back ⇨

with resultant poor, non-decorative, plating on the 'back' or 'inside' for many decades.

Can you do a Hull Cell test and show us the result?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Dear seniors,

We do plating on plastics --

Copper, semi bright, bright, mPS and decorative chrome.

Here I raised my request a few month back regarding white patches.

I still couldn't identify an exact relationship of this white patches but as per my observations I found that parts after semi bright back side of parts are completely dark. It's more in complex shapes.

Can anybody please help me to resolve this?

1. Why blackish may arise behind parts?

2. Is that any organic contamination?

3. Is this happening because of low concentration?

4. Is this happening because of current density?

5. Any relationship with pH?

I'm in immense pressure due to this rejection.

Please help me.

- Bengaluru, India

A. Hi Chandrashekhar. You posted this under a different thread, while I was answering your other question here. Sorry, for the crossover.

But we have asked you for photos of the parts twice now; without them it is very difficult to even understand what defects you are describing. And even if we clearly understood what defects you are seeing, trying to guess whether you should change your level of organics, or your concentration, or your current density, or your pH without knowing any of them is difficult. And you are only now telling us on your third posting that you are plating on plastic :-(

- Do you not have a relationship with a process vendor who can assist you on-site? They are the experts on their processes and the starting point when you have troubles.

- Have you run any Hull Cell panels? Can you tell us what if anything they seemed to reveal about the condition of the semi-bright nickel bath? What do the panels show in the low current density area vs. what you see on the 'black' back of the parts?

- Can you get access to The Canning Handbook [on

eBay,

Amazon,

AbeBooks affil links] which has some charts of typical issues vs. typical causes?

People would surely like to help you but it's very hard to do so without information.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. We are facing some white patches after nickel electroplating

Not in all pcs but find 4-5 percent; also cloudiness in all pcs. So please suggest remedies.

Tools company - Punjab INDIA

May 23, 2019

A. Hi Sukhjinder. We encourage your questions but Mark, David, and I have already suggested remedies for that problem, and with no photos or data, it's hard to know what to add beyond what has already been said on this page :-)

Please send pics to mooney@finishing.com for posting here, and try to offer the type of data requested or comment on the suggestions already offered. Thanks!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello I have problem with nickel chrome plating it has stains and when I use micro to look closely on the stain, it is like holes I don't understand where this came from; is it from the material or due to the process?

Jake Cabreros- Cebu city, Philippines

January 17, 2020

A. Hi Jake,

We need a lot more details, and possibly some photos of the defect.

What is your pre-treatment? What is your plating chemistry? What finishing processes (if any)? What work have you done to try and solve the problem? Have you walked the process yet, to see if there are any obvious errors or if the process has changed from the norm? Have you checked all of your process tanks are within specification or manufacturers recommended limits?

If you can give us more information, you are more likely to get a response.

Aerospace - Yeovil, Somerset, UK

White streaks/patches, and spots, after Nickel Plate

Q. My name is Dustin McAfee and I work for the plating department of a Chiropractic Table company named Lloyd Table Co.

We're based out of Lisbon, IA and do all of our own work from steel and wood, in house. We only outsource to powder coat a variety of parts.

As I said, I work in the plating department where we chrome plate parts for our tables, using a nickel base plate.

I've been having issues recently and it's beginning to get very frustrating. There are so many variables, and honestly I have no technical background in this. I simply know how to get parts from one end of the room to the other.

As the parts come out of the semi-bright nickel bath they exhibit white patches and spots. This is enhanced in the bright nickel, and makes for a very dull, hazy looking areas on the parts.

I have done some looking around online and am in touch with my chemical rep for some assistance, but I thought I would make a post on here to see if any experts out there might have some ideas as to why this is happening. It would be nice to have extra outside input and please bear with me when I attempt to explain things to you, I am in no way an expert but I would love to learn more about it.

Thank You,

Dustin

- Lisbon, Iowa

October 7, 2020

A. The pictures indicate that either the parts were not clean or you picked up floating soil somewhere down the line. Turn off the agitation, let it settle overnight, inspect for floating soil, then blot off with used newspaper.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Thanks for the response Robert. I let the tanks all settle overnight, but the tops seemed free of debris this morning. Could the soil and dirt be underneath the surface?

The parts always seem to look clean when I put them through the initial cleaning process, no water breaks or anything, but could the soil be adhered to the surface and still dirty before they go to nickel?

Our machine shop tumbles most parts in a vibratory cleaner, the two plates were tumble prepped. The shinier looking part has sides on it that are ground with trizact belts to give a "mirror finish" without actually having to buff and polish.

- Lisbon, Iowa

November 19, 2020

A. This looks like pitting to me. If it is, it is probably due to either poor agitation of the electrolyte, poor cleaning of the article, poor nickel bath control and/or composition. The component looks like it is a hemispherical tube, so try putting it in the plating bath with the open side to the top - it the dullness/pitting stops, or appears on the other side, it is a process issue.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

A. Dustin,

The picture looks like a cleaning problem, not pitting -- pitting

⇦ huh? looks like completely round shape.

I saw the picture you posted, Take the part out from the rack after semi bright nickel plate see the condition of this defect, I think check your brightener system may be too much brightener, try to do carbon treat your nickel bath, run the hull cell panel.

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

A. Dustin,

Are you platING copper before you plate nickel, I SAW same condition after copper plate because of over brightener.

Run the hull cell panel 1.'as is' 2. add excess of brightener into hull cell see the same condition on part or not or looks like over etch condition on part.

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

May 30, 2025

Ed. note: Thank you, Popatbhai. It seems like Dustin is not responsive (his question was from over 4 years ago), but other readers will surely benefit from your good advice.

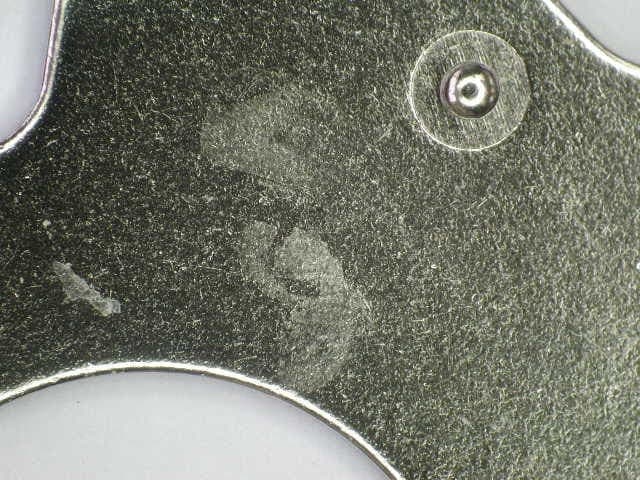

Q. Got White spot on my CRCA sheet after nickel plating. Please let me know the cause?

- Visakhapatnam

November 8, 2022

A. Hi Srikanth. This thread starts with a suggestion that high chloride and/or organic contamination are the two most likely causes of white spots in the general case. However, your white spots certainly look like barrel printout ⇦ huh? to me :-) Are the parts barrel plated? Are the white spots roughly the size of your barrel holes? Can you see a similar white discoloration in the high current density end of your Hull Cell panels? Please provide further data which can be commented on. Thanks!

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Hello, Srikanth,

As Ted asked, it would be useful to know if these parts are rack or barrel plated.

If racked, I believe this could be a pitting problem due to low anti-pitting/wetting agent. Try adding a little bit and see what happens.

Checking the Hull Cell can also help your troubleshooting.

And, Ted, I've never heard of "barrel printout". Could you explain what you mean, please?

Regards,

(affil links)

free pdf is currently available from academia.edu

- Rio de Janeiro, Brasil

November 9, 2022

![]() Hi Pedro. Thanks. "Barrel printout" may not be a perfect term, but what I was referring to is this:

When barrel plating, we sometimes see a pattern on the parts which resembles the pattern of the holes drilled in the barrel. If a component is laying in the plating barrel, pressed against the barrel wall and its holes, there can be a high current density at the holes and not between the holes, which can result in burning, deposition of contaminants like iron, etc. When I see a series of small round discolorations, as on Srikant's parts, I ask myself what might accounts for the discolored areas being round and of consistent size and shape, and I suspect that the discolored areas might be matching the holes in the plating barrel.

Hi Pedro. Thanks. "Barrel printout" may not be a perfect term, but what I was referring to is this:

When barrel plating, we sometimes see a pattern on the parts which resembles the pattern of the holes drilled in the barrel. If a component is laying in the plating barrel, pressed against the barrel wall and its holes, there can be a high current density at the holes and not between the holes, which can result in burning, deposition of contaminants like iron, etc. When I see a series of small round discolorations, as on Srikant's parts, I ask myself what might accounts for the discolored areas being round and of consistent size and shape, and I suspect that the discolored areas might be matching the holes in the plating barrel.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Yes Sir,

We are using barrel type.

- Visakhapatnam

A. Hi

Please check if the white spots match the spacing of the holes in the plating barrel. If so you will need to either reduce the current density to eliminate burning or, preferably, figure out a way to get better parts movement in the plating barrel.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread