-----

Latest techniques for mirror like shining on stainless steel utensils

Q. I am in charge of the new product development for getting mirror like finishing on ss utensils without any scratch.We have tried it by using a flap wheel then giving a coating of buffing compound(made of calcined alumina and wax) and then polishing the surface. But it is not giving the required luster and also it is taking lots of time.Is there any product available that is specifically made for polishing ss utensils and a readymade flap wheel already coated with buffing compound.

I will be interested on the newest technique for the same.Is the size of the abrasive powder is taking a big role ? What is the exact size range for polishing?I have talked with many people but did not get the proper answer.

Thanking you,

- Kochi, Kerala, India

2005

A. I don't think you're ready to automate the process yet if "it is not giving the required luster", Prasanta.

I think you need to find the right abrasive, the right wheels, and the right polishing and buffing sequence and get exactly the right luster. Once that is done, I think you will find that there are automatic polishing and buffing machines available which will disperse the compounds as liquids at the work interface, enabling you to carry out the process at volume and with speed.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2005

A. I agree with Ted. You have to master the process at low volume to proceed to high volume automation. Now, the particle size for mirror finish will be from 4 to 1 microns depending on your "mirror" definition. Also important are the previous finish, exerted pressure and speed and hardness of the base material.

Guillermo MarrufoMonterrey, NL, Mexico

2005

A. Just an add-on for the other good advice. You did not give us any details on the existing surface finish prior to polishing. That does mean a lot in determining the procedures and developing a process and/or equipment.

AF Kenton

retired business owner - Hatboro, Pennsylvania

2005

2005

A. Dear Mr.PRASANTA GORAI

- You can try with a polishing pastes which is used for polishing stainless steel kitchen wares. I don't know the formula.

-- you have to control revolution of polishing device, must be less than 4000 rpm.

--- please try with felt (wool or non-woven) disc/wheel first, than softer one like cotton wheel; at the end, cotton wheel without any paste. Take care about overheating.

---- if not satisfied think "electropolishing" as an alternative; keyword:"electropolishing"

P.S.: Please ask Mr.Ted Mooney, to give you an idea, what are the right abrasives, right wheels, etc.?

Shiny days,

- TURKEY

|

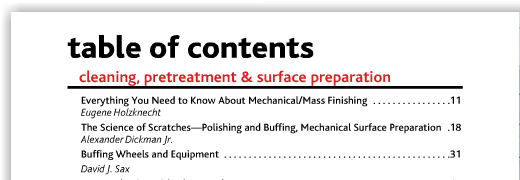

October 2013 Thanks for your input, Zafer. Sorry, I do not have any personal expertise to offer on the ideal abrasives and wheels. However, the Metal Finishing Guidebook has three excellent chapters on the subject. Regards,  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. |

|

Can BFA replace calcined alumina in producing buffing soap for ss utensilsQ. We are producing buffing soap using #325 mesh passed brown fused alumina.The problem we are facing is that it is giving scratches on ss utensils and also not giving the proper mirror like finishing . Whereas green soap mainly produced by calcined alumina giving that luster. Can anyone tell me what is the reason behind that and how come we will get a solution for that problem. - Kochi, Kerala, India 2005 |

ACRONYMS: |

Q, A, or Comment on THIS thread -or- Start a NEW Thread