-----

Soldering the seams of a countertop laminated with .030 zinc sheet metal

Q. I have a woodworking shop that builds cabinets and countertops, in wood, laminates and solid surfacing material.("Corian"). In the past we have built a few counters covered in Zinc metal, however the ones we have done did not require soldering of seams. We are currently involved with a project that requires soldering of seams of a counter we intend to laminate with .030 thick Zinc.

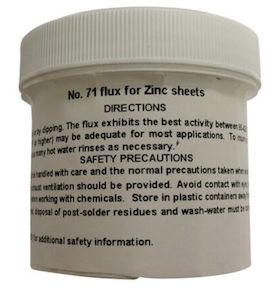

The zinc will be bent on a break and laminated to medium density fiber board with solvent based contact cement. The seams between the sheets will be "tight" but the architect is requiring a soldered seam. Our soldering is limited to plumbing and electrical. Can you give us some info on techniques, tools, solders to use etc. or direct me to trade publication that would educate us in this process?

George D [last name deleted for privacy by Editor]contract woodworking - Linden, New Jersey

2005

Q. Did you find any methods for soldering these zinc seams? I am looking at improved methods for soldering zinc sheet ⇦ on eBay or Amazon [affil link] as well (specifically new electric irons or temperature controlled soldering systems). Thanks.

Jonathan K [last name deleted for privacy by Editor]- Urbana, Illinois

2005

A. Perhaps you could find in your local directory Pipe Organ Builders, they will have in their staff expert pipe-makers who have soldered zinc since they were born.

Hope this helps.

Best wishes,

pipe organ builder - Perth, Scotland, United Kingdom.

February 27, 2008

I have been trying to find information about constructing a zinc countertop that is "L" shaped. It will need a soldered joint. Did you find any information about doing this?

I would really appreciate any help or advice you can give.

- Chelsea, Michigan

September 18, 2008

Hi, Deborah. As Sandy E noted, one possibility is you can look for help from a pipe organ builder.

I understand that it's best to have some mechanical abrasion as you solder zinc plate, such as afforded by the old "soldering bolt" ⇦ on eBay] that was heated in a propane flame, then rubbed on the joint. See topics 15533 and 34726 for some more zinc soldering hints.

But if you are building a countertop, are you sure that you need to solder this joint? A good rolled joint might be more satisfactory. See thread 46075 for a sketch of a joint that an amateur with a little metal working experience could probably do.

Good luck with it.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread