-----

Plating onto sapphire

Q. Hi,

I want to coat sapphire fiber with chromium by electroless technique. Can you suggest the names of companies who manufacture and sell electroless chromium coating solution?

Thank you.

A. I hope a reader will correct me if I am wrong, Debangshu, but I believe that there is no such thing as electroless chrome plating. What leads you to believe that such a thing exists?

But it may be possible to metallize the component first and then chrome plate it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Dear Mr Debangshu B:

Why do you choose electroless chromium coating solution to coat sapphire fiber with chromium? Several years ago we coated sapphire fibers with copper by PVD method with perfect results. I believe that the film obtained by the PVD method is much better than that obtained by solution plating. How thick the chrome film do you want to obtain?

Hangzhou, P.R.C

1999

![]() Hi, Dr. Limin. Thanks for the idea of using PVD, and for helping Debangshu with his need for chromium on sapphire. Yes, PVD is probably right for him.

Hi, Dr. Limin. Thanks for the idea of using PVD, and for helping Debangshu with his need for chromium on sapphire. Yes, PVD is probably right for him.

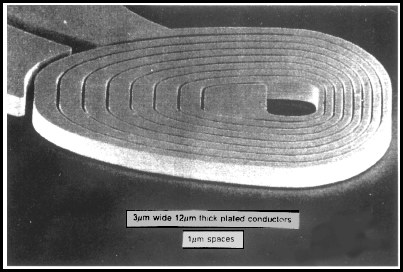

But every deposition technology has its applicability, and I wouldn't want to mislead readers that "the film obtained by the PVD method is much better than that obtained by solution plating" for the general case ... anyone want to try fabricating this electroplated copper component by PVD? :-)

from Electrochimica Acta, Vol. 42, nos 20---- by L.T. Romankiw

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. We'd like to coat alloys such as Aluminum 6061, Copper 14400 and Steel 1045 on small sapphire discs with rough surfaces (Ra values from 0.1 micrometers to 5 micrometers - 4 µ" to 200 µ"). These surfaces will be used in calibration experiments.

Our requirements are that the coating be homogeneous, of the same composition as the alloy, and provides a continuous coverage on the surface being coated, without any gaps. The adhesion needs to be good enough for the coating to not peel off when heated to 200 *deg;C. We do not care about other aspects such as stress in the coating, the temperature at which the coating is produced, etc.

RFQ: We'd like to find vendors who can produce these coatings for us. We'd like to get about 10 sapphire discs of different roughnesses coated with each of the three materials listed above. Each disc is about 12mm in diameter and 2mm thick and only the top surface needs to be coated. Assuming that surfaces of different roughnesses can be coated in one batch, we'll need three batches of 10 discs coated, one for each type of material. We would also like to hear about techniques that can be used for these coatings, potential problems, etc.

Wichita State University - Wichita, Kansas

2005

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. That doesn't sound easy by any technique I know of, but some might exist. Have you considered ion-beam sputter-deposition? I think the compositional fidelity can be a few times better than regular sputter-deposition because it can have 10 times less gas pressure in the deposition chamber, so there's less atomic-weight-dependent scattering loss.

Otherwise, there's plasma spray-gun from wire-stock, maybe some other application of melted droplets, explosive lamination of sheet, arc-evaporation from wire, possibly self-sputtering of some metals from sheet-stock.

Hope you find a way.

- Los Angeles, California, USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread