-----

What is this finish?

Current questions and answers:

March 6, 2021Q. Hello.

Can someone please tell me what this plating (oxidation protective) might been on this metal sheet?

My first thought was that it's just anodized aluminium, but it's magnetic.

So the base must must be steel.

Thank you for your help.

Piotr Czajer- Bensenville, Illinois

A. Hi Piotr. In the picture it looks to me to be blue with white speckles. Is there any reason to think it's other than paint? Is it actually silver colored rather than blue-white and the picture is deceiving?

Trying to guess what such a finish is from just a photo cn be difficult, but if you can tell the readers what the component actually is, it's possible that people familiar with such products will know what the common finishes are. Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

March 2021

⇩ Related postings, oldest first ⇩

Q. Hello,

I am working with a team of auto enthusiasts to make an engine detailing chart for those wishing to restore 1971 Ford 429 engines back to factory original appearance for car show purposes. One area my team needs help in is how to properly identify the coatings we find on original fasteners, brackets and pulleys. I was wondering if you could refer me to a picture chart with photos of parts with various types of coatings we could use as a reference for our project. Just a quick example of our dilemma - we have a gold appearing alternator pulley. Three people have three descriptions - Gold Cad, Yellow Cad, Yellow Dichromate. Perhaps a photo chart would help us identify parts like this correctly with the right terms. Any help you can offer leading us to a photo reference of automotive coatings will be greatly appreciated!

Regards,

John BlairAuto Enthusiast - Westland, Michigan, USA

2003

A. I have been in the fastener business for 26 years, there is only one way to tell the difference in plating types, and color is not one of them. You should look for a local metal finisher in your area. These parts might be i.d. by them, but an acid test is the best way. Different platers have different results in colors of plating, plus how clean their tanks and chemicals are at time of such application ... Good luck!

Rick Pigott- Columbus, Ohio

2006

A. Hello John. Although Rick is surely right, your specific problem with the alternator pulley is probably not to "identify the finish" but to recognize the 'semantics' and phrasing involved in the situation.

Cadmium plating always receives chromate conversion coating as a post treatment. Whether the color of that coating is yellow vs. gold is arguable in every instance; some people would call a chromate yellow that you might call gold and vice-versa. The color difference can be quite subtle, and it can be accidental or deliberate.

On the next point, yes, although there is a chemical difference between chromate (Cr03) and dichromate (Cr2O4), the coating is called a chromate conversion coating regardless of the exact percentage of chromate and dichromate in the coating.

So, a 'gold cad' is cadmium plating followed by a chromate conversion coating which is, to the eye of the beholder, gold in color. A 'yellow cad' is cadmium plating that has received a chromate conversion coating that is, to the eye of the beholder, yellow in color. A yellow dichromate is actually an oxymoron since dichromates are orange, but again it's a chromate conversion coating that is yellow to the eye of the beholder. Identifying the chromate finish without identifying the plated metal would be incomplete though. A 'yellow dichromate' may well mean cadmium plating with yellow chromate, but it could also mean zinc plating with a yellow chromate.

So it's not a matter of deciding which of the three coatings you have based on a color chart; it's a matter of deciding what to call a finish which consists of cadmium plating followed by a chromate conversion coating of a yellowish or goldish tone -- I'd call it cadmium plating with yellow chromate. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I have a garden-variety Chinese lathe (14" x 40"). The handwheels appear to be cast (probably iron) with the center hub and spokes painted, but the outer rim has been machined and appears to be plated. It has a dull, matte silver appearance. Does anyone have an idea what the plating may be, and if I could duplicate it easily in my home workshop?

Thanks,

Roger Head- Australia

2005

A. The initial surface will determine the finish of the plating job; the fact that it is a matte finish just means that the metal underneath had a matte finish when it was plated.

In addition, any plating method (with few exceptions) for use on tools usually involves hazardous chemicals that are difficult and costly to dispose of, and equipment that a hobbyist doesn't have access to.

If you want a clear answer take it to a professional plater and have them figure it out.

Marc Banks- Elizabeth City, North Carolina USA

2005

MGB Windshield Support Posts Coating?

April 28, 2011Q. The more I research this the more I'm perplexed. I'm trying to identify the type of finishing used on the 1965 MGB Windshield Support Posts.

The support posts are made of cast aluminum with a high silica content I'm assuming as when we sanded the surface off and polished the aluminum there is a a very heavy black deposit left on the cloth. This is not true of the un-sanded original finish. This accepts the polish but does not blacken the cloth.

The popular belief is that the support posts are anodized, but the surface coating conducts electricity. I also had an anodizing Co. look at them and they say 'Not Anodized. I have also heard people have tried to anodize with very poor results because of the high silica content.

My next thought is it is a chromate Alodine type coating but in speaking with an Alodine expert they say the high silica content in the alloy is an issue here also and the finish would be uneven.

That leaves me with a huge question. How where these items manufactured in the first place and what is the best way to replicate the original finish.

The attached image shows the original un-sanded piece with coating intact and a sanded and polished piece wanting a new coating.

The original coating is lighter in the picture. Best way to describe it is it looks etched and clear coated in comparison to the sanded & polished item.

The original coating is very thin... sands out easily but is also impervious to aircraft paint stripper.

Any help/ideas would be much appreciated ... I'm pulling my hair out!

Car Restorer - Vancouver, Canada

A. I think you will find that the originals were polished and anodized. The pre anodizing must have included an etch step (hence the semi-bright finish) and a fluoride desmut step which removed much of the silicon at the surface so that the anodized coating is essentially colorless. The anodizing may also have been done to a less than customary thickness to preserve color.

If the surface now conducts electricity, then there is no coating, anodized or organic. It has been removed sometime in the past. Either that or you are probing through the surface coating. To properly test for coating conductivity, use an ohmmeter with light pressure.

None of the above applies to newly manufactured replacement parts. They could be anything.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

May 10, 2011

May 16, 2011

A. I tend to agree with Jeff. They were anodized aluminum. After all these years it may be difficult to get a nice job of anodizing again simply because the castings are old and any debris in the castings may have broken down and oxidized. Consequently there are pockets of onon-aluminum which will not readily accept the anodizing and leaves blemishes.

I think your best bet is to have them polished to a nice bright finish and keep them cleaned and waxed on a regular basis.

Or try getting them painted in a nice bright gray finish that looks close to what they looked like new. Most people will not notice the difference as long as it is well done and all the colors are consistent.

Or course if nothing will do but the original anodized finish then start looking for a reputable place that does custom anodizing and listen very closely to what they say. Too often a customer will have such a desire for a perfect result that they will fail to listen to the possible problems that may occur. Then everybody is unhappy. Of course for the right amount of money anything is just about possible. But estimating a job like that could be off by many hundreds if not thousands of dollars.

Go for the nice matching paint and take the money you save for another project or improvement on your current project.

But hey ! It is only my two bits of opinion.

Of course a real nice chrome job might look good too. Just make sure you find a reputable place. Go to their before and after gallery and make sure they are up to it. Good Luck

- St. Louis, Missouri, USA

A. Hi Julian. You got two terrific responses. The only thing I'll add as a point of general information is that aircraft stripper will remove virtually any organic coating (paint, lacquer. clear coat) but will have little or no effect on inorganic materials (castings, platings. etc.). Other readers should know, though, that it is horribly toxic stuff and only for professionals with proper PPE and training.

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

What is this yellow plating on shoulder bolts

Q. I have a bag of shoulder bolts (M8 x 1.25 x 44 mm) that I found in our warehouse. They appear to be yellow - possibly dichromate finish - but no identification. (They are attracted to a magnet).

Is there a way to determine what the finish is?

- Kansas City, Kansas US

July 22, 2014

A. Hi Joseph. Just from appearance, odds are about 99+% that it's a sacrificial plating of cadmium, zinc, or zinc alloy with a yellow chromate finish.

But whether it's cadmium (which is a bio-accumulative toxin that should be reserved only for very special needs) and whether the chromate is hexavalent (which would be a RoHS problem) can't be determined visually or with normal warehouse stuff. Some plating shops could do spot tests to determine what it is if it's a large enough bag to be worth it. (Are you sure those bolts are new? There is a ring just below the head that looks either much less worn or much more worn than the rest of the shoulder). Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

July 2014

![]() Ted,

Ted,

Thanks! I appreciate your help.

- Kansas City, Kansas US

July 25, 2014

How to identify plating on antique police badges

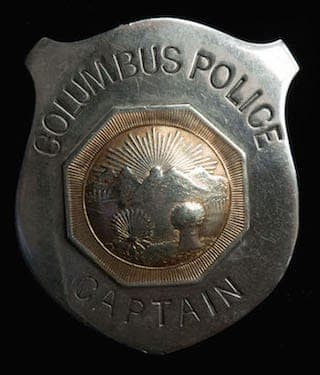

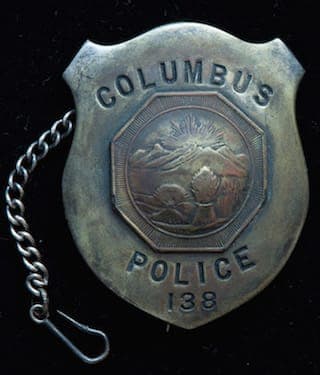

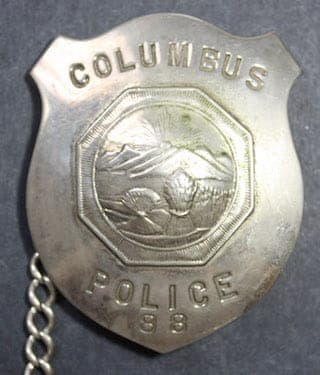

Q. I am trying to identify the type of plating and base metal used on antique Columbus, Ohio Division of Police badges. Research confirms these badges were produced from the late 1870s until 1908. Approximately 14 of these badges are known to exist. The finish ranges from an intact yellowish silvery appearance to completely devoid of finish. Due to their historical significance and value, polishing or destructive testing is not possible.

Museum curator/archivist - Westerville, Ohio

November 13, 2016

Hi Alex. I'm reluctant to guess what the substrate or plating is, but a university in your area will probably have an X-ray fluorescence machine which can answer your questions without polishing or destructive testing. Good luck.

It's interesting that the logo on the Captain's badge is more abstract. Someone knowledgeable in artistic styling trends may be able to say which logo is older based on art trends.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. The badges are most likely Nickel Silver, an alloy of copper, nickel and zinc which contains no actual silver.

The center emblem of the first piece likely had a thin gold plate over plate.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

Identifying finish on old skeleton key

Q. I'm restoring an antique rim lock and key. The key was partly rusted so I cleaned it with Evaporust. Now I'd like to restore the cleaned part to match the original half. Does anyone know what finish was used (see photo)?

The end with the loop still has the finish I'm trying to match. While the design of the lock is mid-19th Century, I don't know if it or the key is a reproduction.

Andy Powershobbyist/restorer - Washington, DC

January 15, 2019

A. Hello Andy, looks like cast iron with a natural black finish which was done primarily with oil. With the level of rust you described, it is very unlikely that the key was plated or had a corrosion protective finish. I also noticed that the ridged part of the key is duller, possibly from wear over time disengaging the tumbler. To keep the authenticity of the key itself, I would try to hand finish with repeated oil rubs, which will help seal the pores of the iron.

Mark BakerElectronics plating - Phoenix Arizona USA

January 15, 2019

Q. Thanks. Do you have any suggestions for the type of oil I should use?

Andy Powers [returning]- Washington, DC, USA

January 18, 2019

A. Hello Andy, boiled linseed oil is a choice of many people.

Mark BakerElectronic Plating - Phoenix, Arizona USA

January 23, 2019

Q. I am hoping to identify a reflective surface that serves as a background for a positive stenciled logo on a 1929 Model A. The body paint appears to be original, suggesting that the reflective surface was applied to the door and stenciled over before the car was ever painted. When I got the car, the logo (reflective surface) was covered with surface rust. It was when I removed the rust that I realized the logo was reflective.

- Meriden, Kansas USA

December 17, 2019

November 19, 2020

A. Re. the Ford logo. I don't recognize this as anything which was done at the Ford factory.

It looks like the work of a later owner/hobbyist - possibly aluminum pigmented "silver" paint.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

Can anyone tell me what this finish is

October 12, 2020Q. I am trying to make repairs to an item but it would help if I knew what repair I need.

Can anyone identify what I need from this picture?

Thank you in advance

Damian

- United Kingdom

A. Hi Damian. From just looking at the photograph it looks like gray/silver colored paint on a white styrofoam or plastic ball. But if you tell us what the part is, what it does, and a theory of what scratched it, better guesses are probably possible. Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

November 2020

Ed. note: No abstract questions

Please, please, pretty please!!

Q. Anyone know how this finish is created?

- OKC Oklahoma

January 29, 2021

A. Hi Mark. I can't get a sense of scale or material of construction. Can you tell us what is is, how big it is, what it seems to be made of, and whether you saw it inside a building vs. out in the elements? If it's outside and showing no rust, I'd guess it's black oxided stainless steel.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread