-----

Counterflow rinsing design

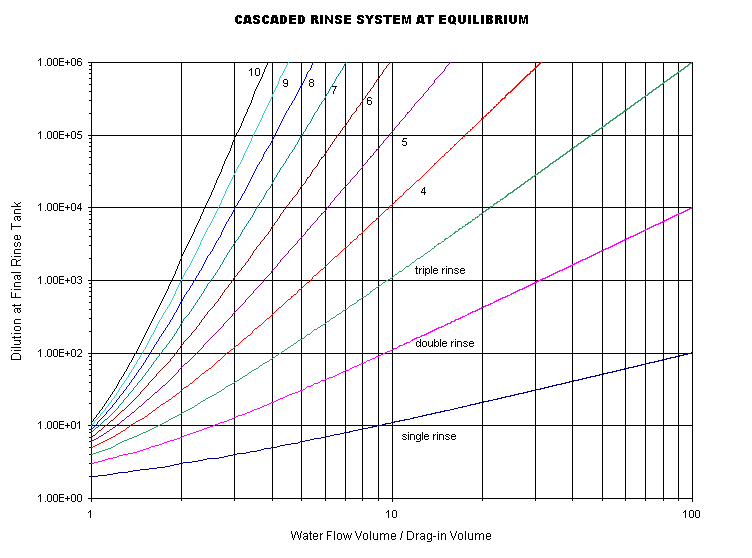

Q. Hello,I am trying to design my PCB workshop (only small production volume) and I am currently concentrating on the rinse problem. Basically I need to design the rinse tanks for each of the processes and my findings tell me that counter-flow rising (cascaded) is my best option. In an effort to find just what cascaded rinsing does I developed a simple computer program that calculates the theoretical dilution of such a rinse system at equilibrium. I have graphed the result from the program:

This graph shows the dilution of the final rinse tank in a cascaded system for a number of different tanks ranging from a single rinse to 10 rinse tanks. The graph x-axis represents water flow volume divided by the drag-in volume. This ratio is assumed to be constant. For example, say 20 ml drag-in occurs each time the job is immersed into a tank, and the water inflow to the last tank is 500 ml per job then this ratio is 25.

I actually measured the drag-in volume for single printed circuit panel of 300 x 300 mm (12"x12") plus the racks 10 ml after it had been allowed to drip for 20 seconds. So, going by this information, using 60 ml of water flow (6 times the drag-in) in a cascaded system of 4 rinse tanks then then final tank will be diluted over 1000 times the processing tank.

My question is how useful is this theoretical information of cascaded rinse system ? Is this how people design rinse processes ? Does it sound like I've done a bad calculation somewhere ?

- Melbourne, Australia

A. Compare your results to mine, which are available in the "The Art and Science of Water Rinsing" chapter of the Metal Finishing Guidebook and let me know what you think.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

The article gives a very good overview of the rinsing problem and wish I had seen it before attempting to develop my own rinse modeling program. It was good to know that I used the same basic assumption mentioned in the article. That is, the bulk concentration of a tank having a continuously flowing stream must eventually stabilize to the same concentration of the stream flowing through it. Going by this assumption a model is easily derived for a single tank. To calculate multiple tanks then a computer just has to iterate the rinsing equation for each tank until the numbers settle down (converge). This is precisely what the program does so I should be confident that it is telling me the truth. I hope the results shown in the above graph find a use to anyone interesting in cascaded rinsing.

Adam Seychell [returning]- Melbourne, Australia

![]() It's a nice, quick, easy to use, graph. Thanks Adam.

It's a nice, quick, easy to use, graph. Thanks Adam.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread