-----

Platinized titanium anodes for electroplating: buying & testing

Q. I work at a reel-to-reel plating facility and we are interested in implementing a system for monitoring the condition of the platinized titanium anodes that we employ on our precious metals plating cells.

My initial thought was to setup a test cell in 1M H2SO4 and run a set amperage through and record the voltage and use that as the gauge of anode health (assuming any deviation >10% indicated coating degradation). Only concern is I'm not sure what to use as the cathode, or if a special "god" Pt/Ti anode could be used as the cathode (assuming it is used only for this purpose).

David De Pena

- Rock Hill, South Carolina

May 23, 2022

Ed. note: While you are awaiting responses to your question, we appended your inquiry to a thread which describes some other ways to determine the anode's condition.

RFQ: Where can I get titanium anodes re-platinised?

Kevin Belanger

- Lawrence, Massachusetts

October 24, 2022

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Coated platinum titanium anode turns black after use

Q. Hello, dear technicians. Our customer purchased the platinum-coated titanium anode, and in the process of use, the anode turned black.

The environment is, anode is positive electrode, negative electrode is solution, there is nickel in the solution, pH is 4, the use temperature is 55 °C. The anode can still be used normally at present, but the color has changed, who can help analyze the reason? Thank you very much

- shaanxi baiji, China

November 22, 2022

⇩ Related postings, oldest first ⇩

Q. How can you test if platinized titanium anodes still have coating of platinum? What can destroy it? This is in reference to chrome related plating. What will be the effect on plated surface? If plating has patches, could it be due to this? (bad electrical contacts are ruled out)

Payal Mag- Charlotte, North Carolina

2001

A. Put a torch to it. If it discolors, there's no Pt left.

James Totter, CEF

- Tallahassee, Florida

A. This is easy. Take a cigarette lighter or small torch and play the flame on the anode mesh until it glows red in dim light. Once it is cooled, if there is an area of discoloration, then the platinum has been plated off. By the way, you can get Titanium or Columbium (Niobium) anodes re-platinized cheaper than buying them new.

Michael Brewington

plating shop - Salisbury, Maryland

A. Look under a microscope to see if you have the Ti showing. It should be gray in color whereas the Pt is black. Also if you have access to XRF and the anode fits in the chamber you could do a spot analysis to see if you have any Pt left. Usually the coating fails by erosion, as you plate you generate lots of gas and the gas bubbles wear away the coating. Another way the coating fails is by porosity in the coating. When this happens you get solution undercutting the adhesion between the Pt and Ti. As for the spots on your parts check the thickness by XRF our what method you use to see if you have a thickness distribution problem in those areas.

George Shahin

Atotech - Rock Hill, South Carolina

A. VISUALLY YOU CAN SEE THE DIFFERENCE IN color OVER A PERIOD OF TIME. IF THE THICKNESS OF COATING IS LESS BECAUSE OF DISSOLUTION (EVEN ITS SAID TO BE INERT) THE COATING WILL DISAPPEAR AND IT WILL BE LEFT WITH ONLY TITANIUM(BLACKISH color). THIS WILL NOT LEAD TO PATCHED DEPOSITION, BUT IT IS SURE TO AFFECT THE CONDUCTIVITY OF ANODE AS TITANIUM IS A POOR CONDUCTOR.

S.J.VENKATASUBRAMANIA RAJA

- HOSUR, TAMIL NADU, INDIA

A. Perhaps you can test the amount of voltage you need to pass the same amount of current in equivalent conditions.

Take a new conforming anode of the same size and shape, and compare voltage required to pass current at 100 amperes per square High anode current density can reduce the life of the auxiliary anode.

Patchy plating could be the result of de-platinized anodes.

![]()

Tom Pullizzi

Falls Township, Pennsylvania

A. Very simple, put the platinised anode in the furnace and heat it up to 500 °C. The result is: oxide is formed as black color in unplatinised area; platinised area is still bright like silver.

Vanajambika Jeyakumar

- Chennai, India

2004

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Why does the titanium have to be platinised and what actually is it.how do you know if a platinised anode has lost its platinum.what removes it?

Martin Humphries

platers - Nottingham, England, UK

2005

A. Platinised titanium is titanium that has been coated with a very thin layer of platinum, normally by vacuum deposition. The purpose of it is to provide a conducting medium that will not react with electrolytes. Platinum is very inert and doesn't readily react electrochemically, so you can do some very good electrochemistry with it. Titanium is used because of its high conductivity and ease in coating under vacuum. Furthermore, if the platinum is porous and the titanium is exposed, the titanium will passivate and soon stop interfering with any electrochemistry going on at the electrode. Once passivated, the titanium can be black or very dark in colour, but a typical characteristic of passivated titanium is its insulation - the voltage will go up for a given current flow.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

A. In addition to Trevor Chrichton's remarks:

Titanium - activated by a platinum or a mixed metal oxide (MMO) layer with semiconducting properties - forms an insoluble anode. Both types of anodes are widely used for very different electrochemical applications (electrowinning, electrosynthesis, electroanalysis, electroplating, cathodic corrosion protection, disinfection and waste water treatment and others). The property of titanium to passivate when anodically polarized is the reason for its use as anode base. The activation must be corrosion-resistant against the electrolyte and must remain active. Any other combination of base metal and coatings fulfilling these two requirements can also be an alternative for an insoluble anode. Even insulating layers like diamond can become active, when doped for instance with boron to make it semiconducting.

An insoluble anode is not insoluble forever but shows a very low 'wear' for whatever reason: very low solubility in the bath or slow complexing with bath ingredients, very low abrasion, losing atoms by gas desorption and by other reactions.

Platinum coatings are applied by electrolysis (molten salt or aqueous electrolytes), by pyrolytic decomposition and even by vacuum deposition or other physical plating methods. MMO coatings are formed by pyrolysis mostly out of chlorides in a multiple step process. The boron doped diamond for instance is an activation formed in a high temperature chemical vapor deposition process.

The insoluble anodes mentioned above differ in their properties. Normally a selection is made for choosing an optimal fitting to an application: being 'only' the counter electrode for the deposition of a metal layer or another reduction process or enhancing or depressing anodic reaction on the anode.

There is a very large field of applications where technical and financial aspects play a role. Customers asking for a special anode should therefore not be worried when anode fabricators ask detailed questions about the electrolyte and the operation conditions. This is for their benefit because anodes not matching with a specific process lead to poor anode life times.

- Usingen, Germany

September 15, 2009

Q. Dear sir,

What is the difference between Molten salt Pt, Galvanic deposition Pt & Thermal decomposition of manufacturing of platinized titanium anode? By which process life of platinized anode be more?

Jay S.

- Rajkot, Gujarat, India

October 6, 2008

A. I can tell you the best anode on the market is the platinum clad anodes. They are formed with a metallurgical bond of copper core, niobium layer, then platinum. "Platinized" anodes are most times platinum plated on a cheaper substrate. I am not familiar with the different mfg. methods you mention, but I do know what works best. I would use platinum clad.

Mark Baker

Process Engineer - Syracuse, New York

Platinum Clad Niobium Anode Mesh vs Platinised Titanium or MMO

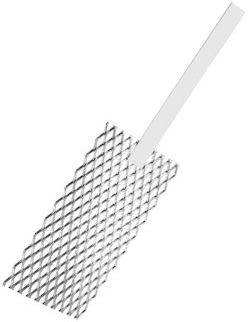

Q. Can anyone cite the advantages of Platinum Clad Niobium Anode mesh against Platinised Titanium Anode mesh and MMO anode mesh. Why do some people need to use Platinum Clad Niobium Anodes in reel to reel plating or precious metal plating or wheel hub plating as auxiliary anodes although the cost of Platinum Clad Niobium anode is much more expensive? What are the benefits outweighing the cost of Platinum Clad Niobium anode or MMO anode?

Kevin Tsang

Plating Industry - Hong Kong

February 6, 2011

A. One advantage of the platinum clad anode is that it can be used at a higher temperature than the other coatings.

Lyle Kirman

consultant - Cleveland Heights, Ohio

RFQ: Dear Sir,

We are an equipment builder for precious metal plating for technical applications.

I need to supply an electroplating line to deposit 7 microns Platinum on Nickel alloy at 92 °C with 0.5 amps /DMsq current.

My Customer insists on using 20 to 30 microns thickness Platinum coated anode mesh. Are such anodes available, if yes, please give me the lead.

Your early guidance will be helpful to complete the project in time.

K. Vishwanatha Aithal

- Bangalore, Karnataka and India

October 19, 2016

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. We use 2 mm dia. platinized titanium anodes to internally plate 5 mm dia. stainless steel tubes. What effects am I likely to see if the Pt coating has been mistakenly removed from the substrate by mechanical abrasion; reduced / poor coverage?

Andy Chris- Brighton, United Kingdom

July 21, 2018

A. Hi Andy

If the platinum has gone you are attempting to plate with titanium anodes. I don't know your process but the titanium will almost certainly anodise and will pass little if any current.

I think you need new anodes.

Geoff Smith

Hampshire, England

Q, A, or Comment on THIS thread -or- Start a NEW Thread