-----

Trying to identify a surface finish note

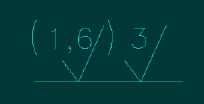

I have a surface finish note or callout that I don't understand. I'll try to describe it... It has a line about an inch long and on the line there are two basic surface finish symbols. One is near the left end of the line and has a 1.6 micrometer spec. This surface finish symbol is in parenthesis. The other symbol is near the right end of the line and has a 3 (micrometer I assume) spec. This symbol is not in parenthesis. Does anyone know what this surface finish note means? The part itself has a 1.6 micrometer surface finish callout on one feature. However, there is also this symbol in the corner of the drawing near the revision block all by itself. It is not attached to the part in any way. What does it mean?

Thanks in advance.

Aaron HaydenCarter Manufacturing Co., Inc. - Grand Haven, Michigan, USA

The symbol means this:

The finishing method (method of machining) is not specified. You have to maintain a Ra(roughness average) of "n" (micrometers/microinches) on that surface. This is a surface texture spec. symbol . The horizontal line is just a leader line used in symbols. Ra 1.6 micrometer finish is produced by grinding, casting/moulding, boring & drilling like operations. In general drawings carry alternate unit numbers in brackets adjacent to numbers of primary measuring units of that drawing. About the number 3 shown in primary units..may be the finish no.(Pls read letter # 7313 of finishing.com. It's talking about surface finish nos.) or Ra 3 micrometers (rougher than Ra 1.6) itself.

1 micrometer = 39.37 microinches

Pls. correct me if I'm wrong.

Natarajan Thirumurugan- Canton, Massachusetts, USA

Earlier we were having single triangle for rough machining, two triangle for fine machining, three triangles for grind finish etc Where can I get more information on this ? Is this system discontinued now?

V Kumarpetrochemicals - Kerala, India

May 24, 2010

October 6, 2011

Dear Kumar,

This link might help.

www.misumiusa.com/CategoryImages/Metric_2006_pdf/METRIC1837-1838.pdf

cheers!

Machinery manufacturing - Matamata, Waikato, New Zealand

Q, A, or Comment on THIS thread -or- Start a NEW Thread