Home of the world famous 'finishing.com HOTLINE' since 1989

-----

Trivalent conversion coatings with hydrogen peroxide added ... why?

Quickstart:

Countless components are zinc plated for corrosion protection. But zinc plating by itself will quickly 'white rust'. Zinc plated parts invariably receive a subsequent chromate conversion coating before the components are shipped.

For many decades there were 2 general types of chromates: trivalent chromates (which offered very little corrosion resistance), and hexavalent chromates (which offered very robust corrosion resistance including the ability to 'self heal' if small areas were abraded). But hexavalent chromates are toxic and considered carcinogenic, and the world is trying to get away from them.

Great progress has been made, and trivalent chromates are the rule rather than the exception these days, offering equivalent corrosion protection to the older hexavalent chromates, but there are still some differences. Read on ...

Q. My question concerns trivalent chromate conversion coatings over zinc. I have noticed that many companies have developed their own trivalent chromate products. We have heard that trivalent chromates do not offer the 'self-healing' properties that hexavalent chromates do, however, some companies offer trivalent chromates that do offer self healing properties. Of those, we noticed that hydrogen peroxide is one part of the bath ingredients. In speaking with a chemist, we learned that hydrogen peroxide will oxidize some of the trivalent back to hexavalent. Should we avoid these products altogether? Do they meet regulations or is this an attempt to work around the regulations that will eventually be uncovered in the future?

Bruce F [surname deleted for privacy by Editor]- Columbia, Missouri

2001

A. Hi, Bruce.

The ingredients in the bath itself are irrelevant to RoHS compliance because it's the finished part, not the chemicals in the bath, that must comply. This peroxide in chromate thing is unknown to me, but can there really be sufficient hydrogen peroxide left in the finished product to oxidize trivalent chrome to hexavalent off into the future? I thought peroxide needed to be kept in sealed brown bottles because it became water and oxygen so quickly out in the atmosphere. Sorry, but I'm not a chemist either :-)

I am a recent convert to believing in trivalent chrome though, and from what I've recently read in some journal articles, it's really Cr+2 that provides the protective value anyway. My present limited and perhaps faulty understanding is that hex chromating is just an easier path to getting the Cr+2 onto the article than trivalent chrome is.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Ted, Now I'm curious. What articles are you talking about? Journals, dates, etc.?

Bruce F [returning]- Columbia, Missouri

2001

Q. Ted,

I'm interested in this whole trivalent vs. hexavalent thing going on. You mentioned journal articles. Could you please post the journals and dates for us?

Thanks,

Brian L [surname deleted for privacy by Editor]- Wolcott, Connecticut

2001

A. Scholar.google.com will probably find good articles. But the most illuminating paper I've seen on the subject is "Clear Chromates - Theory and Praxis" by Dr. Klaus Peter Klos of Elektro-Brite GmbH & Co., Trebur, West Germany. Everyone seems to have xeroxs of this article, without attribution of what conference it was presented at, and I certainly hope it is a public document rather than a pilfered internal one! In any event, try to reach Dr. Klos for a copy of this genuine eye-opener which authoritatively challenges a lot of earlier erroneous assumptions in the literature.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. I use and would recommend contacting SurTec and seeing the article on trivalent passivation posted in June 2001.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

! I have been introduced to trivalent products which utilize hydrogen peroxide. The peroxide is not a component in the proprietary product you purchase, generally the supplier wants you to add a certain percentage of hydrogen peroxide on makeup.

With all due respect to Mr. Mooney. If one is ultimately trying to get to Cr(II) why would there be a need to supply an oxidizing agent to the make-up in the first place. In conclusion hydrogen peroxide is a powerful oxidizing agent, its longevity at elevated temperature is diminished but can easily oxidize Cr(III) to Cr(VI) especially at elevated temperatures.

David B [surname deleted for privacy by Editor]- Columbus, Ohio

2001

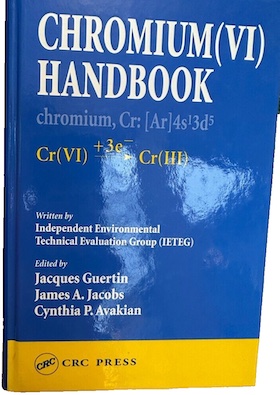

![]() Hi again. This thread is getting confusing to me, but I thought we were discussing a proposition about the role hydrogen peroxide might play in "self-healing of chromate films" -- and whether it could and does oxidize trivalent to hexavalent chromate in order to provide that self-healing power. I am not questioning that hydrogen peroxide can oxidize trivalent chrome to hexavalent in a vat of solution, but whether a chromate film in use in the field can actually retain hydrogen peroxide in order to provide that oxidizing power on a chromated surface.

Hi again. This thread is getting confusing to me, but I thought we were discussing a proposition about the role hydrogen peroxide might play in "self-healing of chromate films" -- and whether it could and does oxidize trivalent to hexavalent chromate in order to provide that self-healing power. I am not questioning that hydrogen peroxide can oxidize trivalent chrome to hexavalent in a vat of solution, but whether a chromate film in use in the field can actually retain hydrogen peroxide in order to provide that oxidizing power on a chromated surface.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Mr. David B,

Langford and Parker, Analysis of Electroplating and Related Solutions [on Amazon, ... on AbeBooks affil links] 1971, page 72, does not mention hydrogen peroxide, mentioning ammonium persulphate or sodium peroxide.

When I oxidized trichrome to hexchrome for analysis in Chromic acid plating solutions, we used sodium peroxide in boiling, acid solution. I believe I was told that in acid solution, hydrogen peroxide would actually act as a reducing agent. The use of hydrogen peroxide would have been much preferred because of its lower cost, safer storage, and ready availability in the laboratory. Sodium peroxide costs about $1.00 per gram, the amount used in our analysis.

The addition of hydrogen peroxide may make sense then, if we want to stabilize an acid solution against oxidation of +2 to +3 chrome ion. And adding hydrogen peroxide upon recommendation of the supplier is one way to keep the cost to the consumer down, and eliminate the problem of packaging (and venting) a volatile, inexpensive component into the rest of the proprietary solution.

Tom Pullizzi

Falls Township, Pennsylvania

Comment: Just a quick note for Tom on why he used sodium peroxide.

You are looking for trivalent chrome right? You first find the hex chrome answer.

Then you oxidise the trivalent to hex by an excess of powerful oxidising agent. You now have a problem that if you test this sample as is you will find out basically how much excess powerful oxidiser you have added.

To remove the powerful oxidiser but not breakdown the hex chrome produced from the trivalent is the problem.

Sodium peroxide is not temperature stable, hex chrome is at the 100 °C mark. That's why you used to boil the sample once the peroxide was thrown in - to remove the peroxide and leave the hex chrome produced from the tri chrome.

You could also use ammonium persulphate.

Martin Trigg-Hogarth

surface treatment shop - Stroud, Glos, England

A. Hydrogen peroxide HAS the ability to oxidize Cr3 to Cr6 in alkaline conditions and reduce hex to trivalent in fairly acid conditions (the pH needs to be lower than for bisulphite). Try adding peroxide to a dilute acid Cr6 solution. It goes through a very dark blue complex which then changes to the green trivalent form.(This is also a spot test for Cr6) If it is used as a reductant in say waste treatment then it is imperative to totally destroy the peroxide (e.g., with Fe) or, when pH is raised it will reoxidise to hex. Re: sodium peroxide when analysing for Cr, it is alkaline so oxidizes Cr3 to Cr6. If you don't boil long enough to destroy ALL peroxide then you will get false results as some, or all Cr6 can be reduced. It is often the reason for false trivalent readings. The peroxide is added to chromate dips to reduce the Cr6 to Cr3. This is one way of making a trivalent clear dip.

Geoffrey Whitelaw

- Port Melbourne, Australia

? I think there are/were multiple discussions interleaved here. Bruce F seemed to be asking if he needed to be concerned about the possibility of the chromate on his components initially passing the standards for hex-free chromate at shipment time, and then later turning into hex chromate in service because there was H2O2 in the processing solution. It struck me (with my limited chemistry knowledge) as farfetched that any small amount of H2O2 remaining on the parts or within the chromate film could have the stability to persist on the parts in service and oxidize the chromate in service after it was found hex-free at shipment.

Geoff's very interesting explanation of bath chemistry seems to resolve the real reason for peroxide in the bath -- not to oxidize trivalent chromate, but to reduce hexavalent! Others may have been fooled, like I was, into thinking that it's purpose was to oxidize trivalent.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. The company I work for has just started to get into the picture regarding the removal of any Hex 6 compounds in products. My question actually has to do with the process of plating this kind of treatment over a zinc based material and we would like to know whether if the trivalent treatment compound is to be used does an intermediate layer need to be applied? How can we increase the amount of corrosion protection that our part can withstand. ⇐ answer?

Your help would be greatly appreciated.

Regards,

Gregory J [surname deleted for privacy by Editor]- Malta

2001

A. Hi Gregory. Years have passed since this thread started, and trivalent chromating is now the rule rather than the exception. Reasonably well developed proprietary trivalent chromates are widely available. They do not need a pre-coat before the chromate but most need a topcoat.

Readers: If this topic is close to what you were looking for, but not 'spot on', you may be interested in thread 45368, "Can Trivalent Chromium degrade into Hexavalent Chromium?"

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

December 2013

WHY aren't trivalent chromates self-healing?

Q. I just want to know why Cr+3 has no self-healing property but Cr+6 has when used in passivation chemical.

Arijit Das- Jamshedpur, Jharkhand, India

May 27, 2019

A. In 2006 I inspected some zinc plated parts that had been treated with a trivalent passivate. I observed that the coating appeared to have self-healing properties rather than functioning as a barrier coating, which was the 'word on the street' (as opposed to published representations). Zachary Kennedy and I investigated this phenomenon and concluded (as published in Plating and Surface Finishing, October 2007) that trivalent passivates function by generating hexavalent chromium during the corrosion process. Since that article was published I know of no published research that has indicated otherwise. A discussion on this great website - https://www.finishing.com/470/49.shtml goes into detail on some of the discussion since the initiation of the EU's insistence on trivalent passivates. It should be noted that some very low-performance trivalent passivates (i.e., bright dips with very little trivalent chromium in them) may not exhibit this behavior - or add much corrosion protection, either. I am curious as to why you posit that trivalent passivates have no self-healing property - have you done experiments? - or is your position based on hearsay? Simple experiments are described in our article.

Tom Rochester

CTO - Jackson, Michigan, USA

Plating Systems & Technologies, Inc.

No dead threads!

Your Q, A, or Comment puts this thread on The Finishing.com HOTLINE.