-----

Non-cyanide silver plating baths?

< Prev. page (You're on the last page of the thread)

Q. Hi

I want to plate Oxygen-free high conductivity copper with silver, for preventing oxidation of copper, so that the conductivity of the copper remains same and doesn't drop! I can't use cyanide solution for plating, so I'm looking for any non-cyanide solution, please do suggest! I have been looking for a very long time, I haven't got anything elsewhere!

Thanks

bye

- Utah, USA

November 23, 2009

A. Hi, Meesu. Although virtually all silver plating is done from cyanide solutions, and has been for a hundred years, many suppliers offer cyanide-free silver plating solutions for electronic use where the color isn't critical. EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser], Technic, and Zinex are three who do so.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. How about trying PVD? It is a pure physical process carried out in vacuum using plasma techniques. I have deposited Cu up to 50 micron thickness using PVD technique. Silver is also easily deposited on copper by PVD processes.

H.R. Prabhakara - ConsultantBangalore Plasmatek - Bangalore Karnataka India

November 24, 2009

Q. Are these solutions solderable? I'm looking for a PCB non-cyanide silver solution

Thanks

- PUEBLA, Pue, Mexico

March 23, 2011

A. Hi, Mauricio

As you probably know, there is much more to successful commercial electroplating than mixing together commodity chemicals. It is typical to use proprietary chemistry rather than generic. Proprietary non-cyanide silver plating solutions are available from EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser] and others, and I'm quite sure that they will advise you that they are highly solderable. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi.

I want to electro-plate Ag on Cu but I don't know the chemical composition and additives to silver bath. Could anyone tell me what to do? What to add to make a good cell, and what is the current density and voltage. Thanks.

- Izmir, Turkey

August 21, 2012

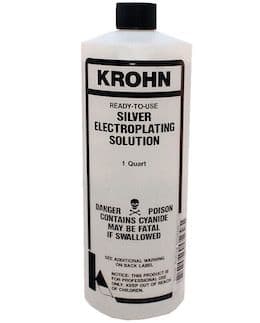

A. Hi Ppsama. If you are interested in resources on this subject, please see our page of recommended books page. The Metal Finishing Guidebook is a good introduction, and widely available everywhere cheap. Silver plating solutions are usually cyanide based (powerful instant-acting poison solution); and accidental acidification can result in airborne hydrogen cyanide (used for executions); and many silver solutions (especially with ammonia ⇦ on eBay or Amazon [affil link] ) can render explosive fulminates.

While it is possible to do some silver plating without understanding every detail, the usual approach is not to mix together the basic chemicals, but to buy a proprietary silver plating solution from a vendor -- which will come with material safety data sheet and a technical data sheet which will answer your questions about operating conditions. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Isn't there any other solution -- for example, nitrate base solution for silver plating?

Ppsama Parsa [returning]- Izmir, Turkey

August 25, 2012

A. Hi Ppsama.

To my limited knowledge, nitrates cannot be used in silver electroplating because they can decompose to ammonia, producing the explosive fulminate products I mentioned.

I'm not suggesting that we wring our hands in despair. Rather, please tell us in detail what you are actually trying to do and why ... from that point we can suggest training, or purchase of proprietary chemicals, or an electroplating jobshop service, or whatever. We're reluctant to suggest doing your own plating, let alone formulating your own plating solutions, when we don't know anything about your situation.

Possibly you assumed that the usual way one gets plating done is to mix up raw materials and do the plating yourself. But the usual way is to send the work to a plating shop, and when that isn't appropriate to a particular situation, it's usual to buy proprietary pre-mixed plating solutions. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

(affil links)

free pdf is currently available from academia.edu

Q. Hi,

I'm an artist, so no silver plating background. I would like to ask for help to please help me to able to start silver plating at home. I would like to use those formulas which do not use cyanide!

I was reading about this on the internet and I found a few article and publications about this:

http://infohouse.p2ric.org/ref/18/17422.pdf

Metal Finishing Guidebook.

Both of them using about the same amount of:

silver chloride 30-50 g/l

sodium thiosulphate

⇦ on

eBay

or

Amazon [affil link]

500 g/l

sodium or potassium metabisulphate 30 g/l

for pH: sodium bisulphte or hydroxide

0,5A/dm2

I found on the internet, the only problem with this is the poor adhesion, so need to do pretreatment, like use silver strike or for a few minutes in ammonium thiocyanate

⇦ on

eBay

or

Amazon [affil link]

.

Ammonium thiocyanate will produce on the polished copper plate copper thiocyanate. This process will produce any cyanide? During this is any cyanide will go in to the air? What will happen if I can't or can wash it properly and after this I will put the copper plate in to the thiosulphate solution? Is any cyanide will be in the air?

Is any other oxidizer will be fine or need to have copper thiocyanate?

artist - Europe, Hungary

A. Try ferrocyanide or pyrophosphate based solution. Ferrocyanide/thiocyanate solutions can be used too. Ferrocyanide based solutions are very stable and results are very good. If you speak or if you can understand Russian there are many downloadable free books on that subject (www.galvanicrus.ru webpage). Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia

January 5, 2013

Q. Thank you for your quick answer!

I'm worrying to use any cyanide based solution, so pyrophosphate based solutions will be better for me. Did you talk about the silver plating solution of the pretreatment solution? Unfortunately I can't speak Russian, so can you offer for me a working formula with pretreatment as well?

AND

Do you know anything about AgCl and KI based silver plating bath? How is it working, is any iodine will be on the surface or in the silver?

- Europe, Hungary

January 8, 2013

Q. I don't know much about ammonium thiocyanate. I saw it somewhere, before pretreatment, for a few seconds I need to put the copper plate in to sulfuric acid and nitric acid, then wash it and then pretreatment, in this case ammonium thiocyanate. If I don't wash it properly and still some acid left on the plate, what will be reaction with ammonium thiocyanate? Is any dangerous reaction can happen, like cyanide gas can go in to the air?

For how long I need to keep the copper plate in ammonium thiocyanate and is the temperature is important?

Can any dangerous reaction can happen between ammonium thiocyanate, sulfuric acid, nitric acid and silver chloride?

- Europe, Hungary

January 9, 2013

A. Try next webpage http://attachments.wetpaintserv.us/ZLSnLKosv0l3CnE9hGDi7w488720

There you can find download free booklet on cyanide free metal plating and metals colouring. Ferrocyanide solutions are very safe and stable and cannot be compared with potassium or sodium cyanide based solutions (deadly poisons!); and from historical point, ferrocaynide based solutions are oldest cyanide-free plating solutions (Elsners bath 1842!) Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia January 11, 2013

Ed. note Jan 2017: Although wetpaintserv.us was a legitimate site when Goran posted this, it is currently a malware site. DON'T GO THERE!! Goran has been kind enough to upload his booklet to https://www.finishing.com/library/budija/kembojen2025.pdf.

January 11, 2013

A. Try next link :

patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO2&Sect2=HITOFF&u=%2Fnetahtml%2FPTO%2Fsearch-adv.htm&r=41&f=G&l=50&d=PTXT&p=1&p=1&S1=%28%28%22plating%22.TI.%29+AND+silver.TI.%29&OS=TTL/%22+plating%22+AND+TTL/silver&RS=%28TTL/%22+plating%22+AND+TTL/silver%29

(expired USA patent /iodide based silver plating bath). Hope it helps and good luck!

- Cerovski vrh Croatia

June 10, 2014

Q. I would like to silver plate small copper sheets. Those copper plates have mirror like surface. My silver plated copper should have a mirror like surface.

Do you have any experience with any of the following baths? Can you offer for me a working bath recipe to get good silver surface?

I found informations about succinimide, thiosulphate, 5,5-dimethyl hydantoin and about potassium iodide based baths. These bath recipes from patents from the internet.

For me succinimide based bath was the most promising. I bought the ingredients, but before the first try I found an article about stability problems. If I don't use the bath do I still have to maintain the bath pH regularly? How often? And if I won't, just before the next use? Something like this:

AgNO3 36 g

Succinimide 55 g

Potassium nitrite 42 g

Diethylenetriamine 2 ml

pH9,5 with Potassium hydroxide

5,5-dimethyl hydantoin is in the most recent patents but no information about how to maintain it. So how to maintain it?

Silver ions as silver 5,5-dimethyl hydantoin 40 g/L

5,5-dimethyl hydantoin 70 g/L

sulfamic acid

⇦ on

eBay

or

Amazon [affil link] 35 g/L

Potassium hydroxide 50 g/L

Potassium nitrate 15 g/L

2,2-thiodiethanol 8 g/L

pH 9.5

Thiosulphate: poor adhesion... What does it mean poor adhesion?The silver will peal off from the copper?

Potassium iodide: Not much information about bright silver plating with this. Do you know how to make bright silver plating with this?

Silver Iodide 41 gm/liter (.175 mol/liter) Potassium Iodide 400 gm/liter (2.41 mol/liter) Calcium Formate 16 gm/liter (.123 mol/liter) Sodium Nitrate 40 gm/liter Gelatin-Purified 2 gm/liter Calfskin _

artist - Gyor, Hungary

A. Hello Maac,

The only person(s) that can answer your questions is someone who has experimented with a non-proprietary bath. The people that hold the patents will not reveal anything. I installed my first non-cyanide silver bath in New York City in 1992. At the time, I worked for a leading company that specialized in precious metals for electroplating, so I had plenty of technical support from headquarters. I think your best bet is to go with a proprietary bath so you can get the support and service you require.

Process Engineer - Malone, New York USA

June 11, 2014

A. Try ferrocyanide bath; ferrocyanides are non toxic cyanide compounds and that type of bath is very stable and easy to prepare. According to old russian books, it can be used for bright plating too. Formula: 40 gms silver chloride, 200 gms potassium ferrocyanide ⇦ on eBay or Amazon [affil link] , 20 gms potassium carbonate, 1 lit water, stainless steel anodes. Hope it helps and good luck!

Goran Budija- zagreb,Croatia

June 14, 2014

!! But ferrocyanide with acids still can produce hydrogen cyanide, which is toxic. And you have strong acids around, because of the cleaning step.

Maac Bakody [returning]artist - Gyor, Hungary

June 15, 2014

A. Yes, but there are no perfect solutions, even cyanide free plating solutions are more or less toxic. Ferrocyanide based technology is simple, safer than cyanide based, very stable, and results can be very good. You can try pyrophosphate based bath (see my previous answers, formula from old ex USSR books). You can buy proprietary bath too.

Goran Budija- Zagreb,Croatia

June 17, 2014

Non-cyanide Silver Electroplating rubs off with a pencil eraser

Q. I help manage a non-cyanide silver electroplating process designed by Technic Inc. Our plating components appear to plate ok, but when we take a hard eraser to the surface of the component, we can rub off the silver to reveal copper underneath. We have been trying to experiment with the time in the plating tank and the amps delivered to the plating tank to try and increase the durability of the silver component. We clean the components in a heated alkaline cleaner solution as well as 10% sulfuric acid before rinsing them and plating the components.

We have been running this process for over a year, and the original components did not have this problem. Does anyone have any ideas that could identify the problem or improve our component durability?

- Chicago, Illinois, US

November 10, 2014

A. Hello Christopher,

If all the components in the bath are within operating parameters, I would ask Technic if it's time to carbon treat the bath. I have used a SOFT ERASER before to "polish" dull finishes, but never a hard eraser. As you know, silver is a soft metal and depending on your plating thickness, it may rub off. I would also verify the plating thickness to be sure you are getting what your requirements are. If this eraser test you perform is for adhesion testing, why not perform a bend test on Cu wire? If memory serves me correctly, there is a dilute sulfuric dip after the Ag plating process. Is the dip within operating parameters? A simple lab titration will verify this. Hope this helps!

Process Engineer - Phoenix, Arizona USA

November 19, 2014

A. Seems your silver strike is too high in metal.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

November 20, 2014

Q, A, or Comment on THIS thread -or- Start a NEW Thread