-----

Albaloy, Miralloy, Optalloy copper/tin/zinc alloy plating

(courtesy of https://www.gammaelectronics.net/why-you-should-use-tri-metal-albaloy-connectors/)

Current question and answers:

Buenas tardes don baudrand

Seria tan amable de publicar la composición, proporciones y condiciones del baño de bronce blanco.... agradeciendole por anticipado feliz año nuevo

- lima [Peru]

January 5, 2022

A. Buenos dias, Martin. Apologies but we cannot offer postings in Spanish or other languages. Don's posting was from 11+ years ago so he's unlikely to see this, although he is welcome to publicly reply as are other readers.

Meanwhile you might consult Brenner's "Electrodeposition of Alloys" ⇦[this on Amazon, eBay, & AbeBooks affil links] which includes 6 pages on the subject; or, better yet, find a process supplier who offers white bronze plating processes because they're not easy to formulate, operate, or control -- and guidance from the supplier can prove invaluable.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2022

⇩ Related postings, oldest first ⇩

Q. I'm looking for information on a copper/tin/zinc alloy process marketed under a variety of names including Albaloy, Miralloy, Optalloy. I worked with the process some years ago and have contacted a couple of vendors for updated information, but it seems little has actually ever been published. I think the process dates to the 1940's. what I am really after is real-world experience pertaining to this alloy. Bath makeup, maintenance, and life cycle would be appreciated. Also desired is information on deposit properties such as solderability, shelf-life, corrosion resistance, and electrical properties. Finally, are there any non-destructive thickness methods available (can you do XRF on the deposit)? Thanks

Bill Vins

microwave & cable assemblies - Mesa (what a place-a), Arizona

1995

Q. I need some information about Optalloy, that includes formulation and characteristics.

hassan karamitarbiat modarres university - tehran, iran

2000

A. Hello Hassan. There is renewed interest in this these days because of the need to eliminate nickel plating from jewelry. While some of those older trade names may still be in use, it is usually just called "white bronze" plating these days. It is in wide use in many countries (less so in the USA because we do not have a ban on nickel in jewelry as many other countries do). I heard a good presentation about white bronze recently by Uyemura.

Sorry, but Optalloy is a trade name so we cannot post its formulation info if anyone offers it. But published info on "white bronze" plating is welcome here. It apparently is a difficult process to operate because keeping 3 elements in balance in the deposit is tough, plus the tin tends to oxidize and precipitate out (or at least become unavailable for deposition)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. "Optalloy" is the registered trade name of an electrolytically plated Cu-Sn-Zn Alloy. Such alloy under the name of Optalloy is available at Collini-Fluhmann AG in Switzerland.

Dr. Hubert A. Braun- Dubendorf, Switzerland

2001

Electrical & magnetic characteristics of Miralloy?

Q. I would like to know electrical characteristics for Miralloy and to know if it can replace Optalloy (regarding electrical and magnetic data), as our supplier finds it difficult to get Optalloy.

Luigi Ravaglia- Monza, Italy

2001

Albaloy plating specs & technical data

2003Q. I am trying to gather specific technical data on Albaloy plating such as it's:

spec. resistivity;

spec. conductivity;

Contact resistance;

Hardness;

Ductility;

Corrosion resistance;

and any other physical and chemical properties to see if it is suitable for my RF application.

- Franklin Park, Illinois

A. Hi, Robert. Albaloy is a cyanide-based product and not suitable for hobbyists, and I'm not sure from your posting whether you are a hobbyist working on RF gadgets yourself or an OEM designer who is specifying the process.

It is rather difficult to plate white bronzes like Albaloy because they are an alloy of three metals. So you may want to rely on a proprietary product rather than a generic one. Uyemura markets a proprietary white bronze plating bath which you may wish to contact them about. Presumably they will have the answers to your questions about the properties of the material. Good luck

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Need Plater for Miralloy Finish

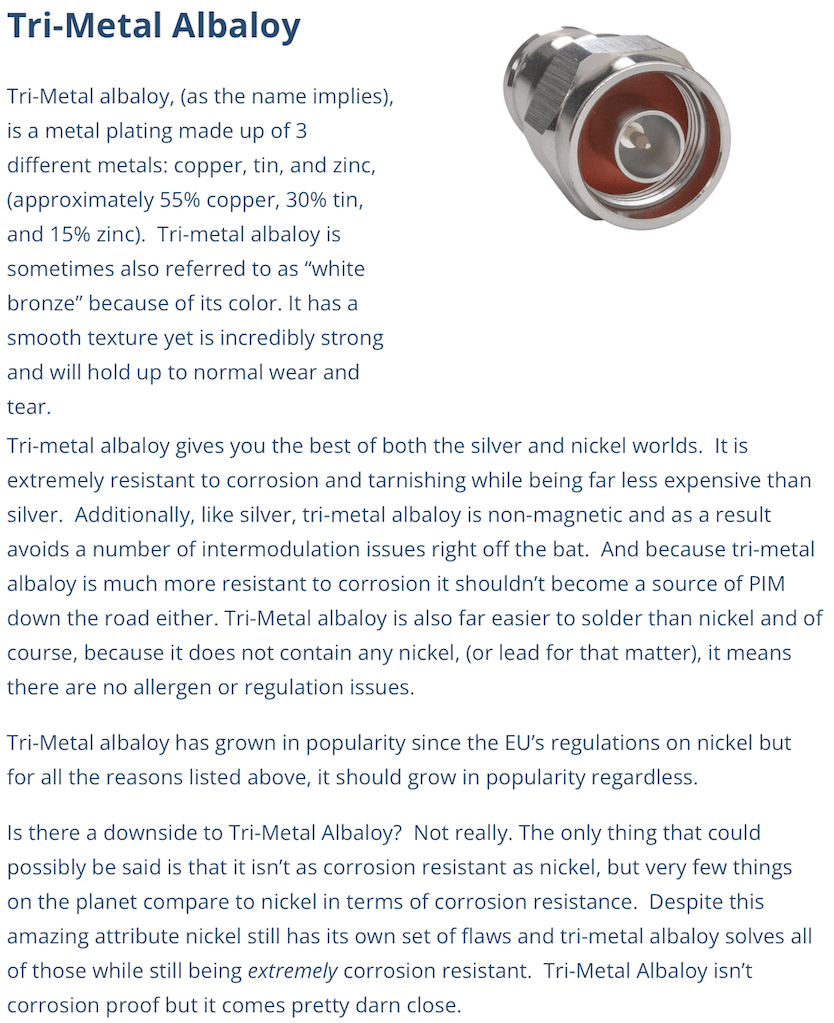

RFQ: I work for a company that makes telecommunications equipment, need particular type of plating. I am searching for an Asian plater that plates a finish called "Miralloy" with diamagnetic layers. The general composition of Miralloy is 55% Cu - 30% Sn - 15% Zn.

Chenweijun [last name deleted for privacy by Editor]Engineer - Qingdao, Shandong, China

2004

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

2004

Q. Dear Sir,

I am exporting silver jewelry & I have got an inquiry from someone asking what is

1)80 Miralloy

2)300-600 bright acid copper.

Could you please tell me what does this stand for..is it some kind of plating on silver jewelry?

With Regards,

Exporter - Mumbai, Maharashtra, India

A. Hi Nita,

Miralloy is brand name of company which provides alloy chemistry of tin and cu under this flag at different alloying ratios.

Regards

- Ajman, United Arab Emirates

2004

2004

A. Nita

Miralloy as stated by Mr Qutub is a bright white Bronze plating system of a proprietary nature used to plate a white bright corrosion resistant layer of White bronze over any acceptable base such as acid copper.

Acid Copper is the name of a type of copper solution which is acidic in nature, produces bright and well leveled deposits and is a preferred undercoat for many applications. Both systems are indigenous.

Regards,

Asif Nurie [deceased]

- New Delhi, India

With deep regret we sadly advise that Asif passed away on Jan 24, 2016

A. Miralloy is a brandname of "Umicore Galvanotechnik GmbH, D-73575 Germany" - formerly known as Degussa Galvanotechnik.

Uwe Seber- Leinzell, Germany

2004

Need a control plan for Miralloy process

Q. Sir,

I am quality control engineer in this concern. I so happy now getting you. I am expecting control plan for Miralloy electroplating process or general control plan for electroplating process. Can you provide me sir?

Thank you sir,

Yours truly,

- Bangalore, Karnataka, India

2004

A. It would take hours for someone to do that and it would be general and not specific to your facility, so would be in error or incomplete. Hire a consultant or do lots of homework.

James Watts- Navarre, Florida

2004

A. Miralloy is a proprietary process. The supplier of the process should be able to provide you the Technical support or provide the Tech Service Guide which should contain the control plan that you require. By the way do you do White or Yellow Bronze?

T.K. Mohan

plating process supplier - Mumbai, India

2004

Composition of Albaloy

Q. I am interested in finding out the composition of Albaloy and how does it compare in composition with Tri-Alloy, White Bronze, Sucaplate, Tru Luster, etc are all these coating the same ratio of copper, tin and zinc?

George S Bognarmetal finishing shop - WEST PALM BEACH, Florida, USA

2004

A. Albaloy is an electroplatable three metal alloy comprising copper, tin and zinc. It is also know as "white bronze" or "sucoplate". It has been receiving increased interest as a substitute for nickel as a barrier layer in jewellery etc, since the EU has banned the use of nickel in such articles. I believe it also goes under the trade name of "Miralloy".

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

2004

November 4, 2010

A. I have been having quite a look at these and each appears different with varying properties. What I have found is:

| Copper | Tin | Zinc | HV | |

| White bronze C60 | 58-62% | 20-24% | 15-28% | 340-370 |

| Albaloy | 55-60% | 20-25% | 15-20% | 300-380 |

| TRI-M3 | 50-55% | 30-35% | 13-17% | 500-600 |

| Miralloy | 50-55% | 30-35% | 13-17% | 600 |

Bob DeLong

- Prescott, Arizona USA

Multiple threads merged: please forgive chronology errors and repetition 🙂

2006

Q. Hello all, I worked in the Tektronix plating department from 1979 until 1990. We used a Cu-Sn-Zn bath patterned after H-VW-M's "Albaloy" solution. I would be interested in any data sheets, formulation, or really any info that any of you might have. Best regards, Marianne

Marianne McPherson

- Santa Barbara, California USA

A. I was in the equipment division at M&T Chemicals/H-VW-M, so I don't have any data sheets for H-VW-M processes. But I do have a large collection of Metal Finishing and Plating magazines if you know of anything published about it.

One thread here says Albaloy is still available from Atotech. Another says Technic's TechniWhite is a successor to Albaloy. A third says a similar process called Miralloy is available from Degussa Galvanotechnik, marketed in the USA by Uyemura International Corp. And a fourth suggests Enwhite 100 system from Engelhard CLAL of Singapore and France.

Epner Technology in Brooklyn and Precision Plating in Chicago claim to do Albaloy plating and might be able to help with formulation, etc.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

2006

Badly need guidance on Albaloy plating bath analysis

Q. Hi, my name is Jerry and I'm a plater for a electronics company. My question is about the Albaloy bath I use. Can I determine the copper, tin, and zinc concentration by using titration methods? My vendor tells me the only way is by AAS. I am currently using an x-ray machine but, this method seems to be inaccurate and inconsistent. If I can use titration methods PLEASE, can you tell me the procedure for each metal?

thank you,

lead person - Beverly, Massachusetts, USA

2007

A. Hi Jerry

You should be able to use your x-ray machine for all three of these metals - especially if you are trying to measure them at g/L or % types of levels. I would use the method of standard additions and it should work.

- Auburn, Washington

A. A Google search on "Albaloy" tells me that it is a cyanide based alkaline formulation, also known as "white bronze."

Zinc can be determined as in a brass solution: titration with EDTA after blending with a pH 10 NH3/NH4Cl buffer, and a formaldehyde addition. The indicator used is eriochrome black t

⇦ on

eBay or

Amazon [affil link]

; the endpoint transition is red to blue.

Copper, plus zinc, will come up in an EDTA titration also. The cyanide is destroyed, via the addition of hydrogen peroxide, and subsequent addition of HNO3 and H2SO4 (caution! cyanide gas released!)and heating to white fumes. Water is added after cooling, aqueous ammonia

⇦ on

eBay or

Amazon [affil link] added just to a blue color, PAN indicator solution added, and the mixture titrated at about 140 F with EDTA to a light green endpoint. A little arithmetic, subtracting the Zn number, yields the Cu number.

Tin can be determined as in a bronze solution. A suitably sized sample is combined with about 40 ml of conc HCl (caution! cyanide gas released!) and heated until gas evolution ceases. About 60 ml of water and 2 - 3 g iron powder are added, and the mixture boiled until the iron dissolves. About a gram of NaHCO3 is added, the mixture covered loosely, and allowed to cool. A bit of starch indicator is added, and the mixture titrated to a blue endpoint with iodine solution.

If I was mistaken about this being a cyanide formulation, and the complexant is some kind of organic chelator, the zinc determination has to be finagled - a good sharp acid digestion, followed by ammonia addition to pH 10, will get rid of the chelator and allow titration in the usual fashion.

Dave Wichern

Consultant - The Bronx, New York

A. Minor amendment: If you do the acid digestion for Zn in a non-cyanide formulation (if that is what you have) after the post digestion elevation of the pH, you need to add 300-400 mg of sodium cyanide to mask the copper. When you add the formaldehyde, the zinc will be unmasked, but not the copper.

Dave Wichern

Consultant - The Bronx, New York

Need MSDS for Miralloy and Optalloy

Q. I want MSDS for the two products Miralloy or Optalloy. Thanks. Best regards

Colby Aresshop - Brazil

January 10, 2008

Need Plater for Miralloy Finish

RFQ: Need plater for Miralloy finish INDIA,

We are a company manufacturing various electrical accessories, We need to plate our components to MIRALLOY (Cu-Sn-Zn) system.

ELECTRICAL MFGR - MUMBAI, MH, INDIA

March 5, 2008

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. Presently the only known Albaloy Chemistries have been in Cyanide based chemistries. Are there Controllable Albaloy chemistries in sulphate type or MSA type chemistries.

Also regarding Albaloy anodes: years ago there were companies producing Albaloy anodes. Are there companies still producing such anodes?

plating consultant - Yorba Linda, California

July 26, 2009

Multiple threads merged: please forgive chronology errors and repetition 🙂

More info about Albaloy

Q. Is Albaloy a trade name and if so whose? I would like to obtain the applied material specifications such as Vicker's hardness and conductivity.

I am finding many tri metal coatings with just slight adjustments in the element percentages but with much different hardness ratings. Is the process that variable? For example the harness ranges from 300 to 600 HV. How do you insure the plating house will hold this in a reasonable range?

Is this material suitable for impact wear performance or will it work harden and flake off?

Engineer - Prescott, Arizona, USA

November 4, 2010

A. Albaloy is an electroplated alloy of copper, tin and Zinc. The deposit is very corrosion resistant easy to solder. it is relatively hard, but I do not know the hardness number.

I have plated Albaloy (many years ago). I have the formula for the plating solution. It is not a registered trade mark, and I don't know of any supplier that sells the solution chemicals as a plating solutions. Some brighteners can be used, but usually no brightener is used.The deposit is metallic white. It was used for fuse bodies and I think it may still be used by fuse makers.

Don

Don Baudrand

Consultant - Poulsbo, Washington

(Don is co-author of "Plating on Plastics" [on Amazon or AbeBooks affil links]

and "Plating ABS Plastics" [on Amazon or eBay or AbeBooks affil links])

Q. Help! I teach jewelry making in a public high school and the cost of sterling is becoming prohibitive. I am exploring "white bronze" (yes, I know it is not technically accurate) as a way to provide a white metal alternative to Sterling that does not cause skin and discoloration problems.

I realize that white bronze is known also as Miralloy and several other names, mainly related to plating processes. Is this metal available in sheet and wire?

I have 28 students currently enrolled in jewelry making, it is very frustrating that the costs of sterling are restricting them to pieces that cannot be worn … we have been working mainly in copper.

Any help or suggestions are very appreciated! Regards, Mary

public school education - Houston, Texas, USA

April 12, 2011

A. Try nickel silver or monel metal, or even pewter. White bronze can be plated from cyanide and cyanide-free baths.

Imitation chrome plating can be good option too: 20 gms cobalt sulphate / 10 gms

⇦ on

eBay

or

Amazon [affil link]

/ 50 gms citric acid

⇦ on

eBay

or

Amazon [affil link] /1 lit water -- according to USA patent USPT 4,299,671. Hope it helps and good luck!

- Cerovski vrh Croatia

Q. Hi,

I work for a jewelry company in the United Kingdom and we use White bronze as a coating to protect silver plated jewelry. We use X-ray Fluorescence to find out the microns of the plating, but we are struggling to get a reading for the white bronze. This could be a number of different factors, but what I wanted to know is can suppliers cut corners in the process to plate the white bronze/miralloy?

I have done some extensive research into Miralloy, Optalloy, Albaloy or white bronze (depending what people know is as) and I cannot quite figure out a way to see how our suppliers are producing it.

Any feedback would be grateful.

- Oxfordshire, England

October 2, 2015

A. Hi Grant. White bronze is an alloy of tin, zinc, and copper -- which must be in proper proportion. This is not easy because the greatly differing electromotive potentials require tight sequestering of the metals to make their deposition potentials similar; plus the tin content tends to oxidize, rendering it unusable. I'm not sure that I understand the question, but white bronze is a very real plating even if the methods are not public knowledge.

Hi readers. This is a largely anonymous internet forum (no registration, and fictitious names sometimes slip through), so we must guard against accidentally assisting in crowd-sourcing of industrial espionage. We'll be pleased to post any offered links to patents or published info, but we can't directly post formulation info except offered by people well known to us.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I have also been looking into using white bronze. My main purpose however is to use it for a diffusion barrier between copper and gold. Will a non-white bronze plating system act in the same way although it is not "white bronze"

Ryan Kuhns- Denver, Colorado, Park

February 25, 2016

A. Excellent question, Ryan! Nickel is an excellent diffusion barrier, but you may not want to use nickel.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello, could you send me analytical control for this process?

I work with this process, but I don't have information.

- Lima, Peru

February 26, 2019

by Abner Brenner

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Karina. If you are using Uyemura's Miralloy process you can request their technical data sheet from their website. If you register at IEEE Global spec you can supposedly download Technic's Techniwhite data sheet for free (but I didn't register so I can't vouch). A few minutes of googling did not reveal any other current sources for technical data sheets for white bronze plating.

Surfacequery.com lists a number of articles on the subject, including some that perhaps address metal content of the deposit, but probably not analytical control. Brenner has 6 pages on copper-tin-zinc alloys.

Good luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Ed. note Jan. 2022: SurfaceQuery.com is not on-line anymore. Don't go there as it now forwards to a site having nothing to do with this, and which might expose you to malware.

Or see these related threads:

• Topic 34483 "Imitation Rhodium Plating Chemistry?"

• Topic 49751 "White Bronze Plating: an alternative to nickel"

• Search the site with 'white bronze' or trade names of white bronze platings for many other threads

Q, A, or Comment on THIS thread -or- Start a NEW Thread