-----

Aluminizing Q&A;s

Q. I am a student who is working on the effects of flux in hot dip aluminizing. I need the names of some books or articles about it.

Ma Sha- India Delhy

2000

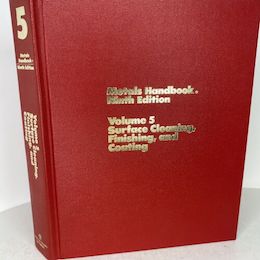

9th Edition, Vol. 5

"Surface Cleaning, Finishing & Coating"

on eBay or Amazon

or AbeBooks

(affil link)

Q. Type II hot dip aluminized steel: performance in storm drains or pipes?

Peter ElliottConsultant - Colts Neck, New Jersey, USA

2006

2006

A. There is a fourteen-page chapter on "Aluminum Coating of Steel" in ASM Metals Handbook, Ninth edition, Vol. 5, "Surface Cleaning, Finishing and Coating".

The newer edition "Surface Engineering" may have some of the same information scattered through it, but it is not accessible as a chapter.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I need information about aluminizing steels.

Thank you,

Silvio Jose GrandoForjasul Canoas S.A. - Canoas, RS, Brazil

2001

[Portugese > English machine translation of posting]

A. Steel has been aluminized to increase the corrosion resistance at high temperature in media containing H2S and SO2 / SO3. The aluminized carbon steel strength is reported exceed or even like a stainless steel submitted to test high temperature oxidation. The process that has been used is for diffusion in high temperature with the piece to be coated immersed in media rich in aluminium.

Flávio Augusto dos Santos Serra- PAULINIA, SP. Brazil

2003

Thesis about aluminizing

Q. Dear sirs,

Kindly inform you that I am a student and my thesis is about aluminizing process and equipment, I have a little information about it , if you know something about it (especially about the companies who sell its equipment)please send me that.

With the best regard,

Leila AkbariIranian University of Science and Technology - Arak, Markazi, Iran

2003

2003

A. There are several very diverse aluminizing processes:

Hot-dip. Similar to hot-dip zinc galvanizing. See the GALVANIZING, ALUMINIZING, HOT TIN DIPPING area on this site.

Hot spray. Deposition using a flame or electric torch.

Pack metallization. Diffusion of Al vapor into a substrate from a high temperature mixture containing Al, a halide and an inert ceramic. Similar to Sherardizing process for zinc coating.

Vacuum metallization. Either Al evaporation or ion implantation. Highly reflective, and can be performed on plastic, glass, etc. E.g., see letter 23827 (www.finishing.com/238/27.shtml) and letter #23383 (www.finishing.com/233/83.shtml).

Electrodeposition. Rarely done, requires an organic solvent and protection from water and oxygen (glovebox work).

I suggest an Internet search on the particular topic of interest.

Ken Vlach [deceased]- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

20062003

A. Aluminizing is coating of steel (sheets) in molten bath of Al-Zn coating. There are 2 types of process.

I have done research on the batch type with the following: withdrawal rate=15cm/min. Preheating temp. °C. Superheat temp.= 50 °C above the liquidus temp. These are fixed parameters. The process variables are the Al content 0,2,4,6,8,10,45. Don't try above than 8 because the molten bath becomes aggressive. Dipping time 1-5 min.

The process as follows: 1 sample preparation (..cleaning, pickling, fluxing). 2 drying 3 immersing the sample,

- Kuwait

Aluminum coating on the aluminized tube weld bead

Q. We are steel tube manufacturers , we are currently in to the aluminized tubes manufacturing. Now we are in need of coating the welded area of the tube to a quality similar to that of aluminizing the strip. But this has to be done online preferably in the tube mill. Kindly suggest a suitable method and equipment.

PratheepTube manufacturer - INDIA

2005

2005

A. Hello Pratheep;

For your application I would suggest that you go for thermal spray of similar metal on the weld portion.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

Aluminizing steel with colour anodized aluminum and silicone

Q. I am trying to color a steel product with various dyes. The colors would include Black, grey, red, blue and green. Would it be best to first anodize the aluminum silicone mixture and then aluminize that to the steel product?

Is there a/another way to color steel while maintaining a strong resistance to abrasion and salt.

Mitchell Johnson- Windsor, Ontario, Canada

September 25, 2015

Q, A, or Comment on THIS thread -or- Start a NEW Thread