-----

The properties of 10B38 steel?

(courtesy of https://www.siegalsteel.com)

Q. Hello. I want to produce 10B38 alloy with induction furnace. I need help with how much boron I add to steel alloy.

Thanks

Producer factory management - Qom/iran

December 18, 2021

⇩ Related postings, oldest first ⇩

Q. Hello,

I would like to know the material properties of 10B38 steel. I am looking for properties like tensile strength, modulus of elasticity, and density. I searched all over the web for an answer, but came up empty so I figured I would try posting my question here.

- Grand Rapids, Michigan, USA

2001

A. Hello Kevin!

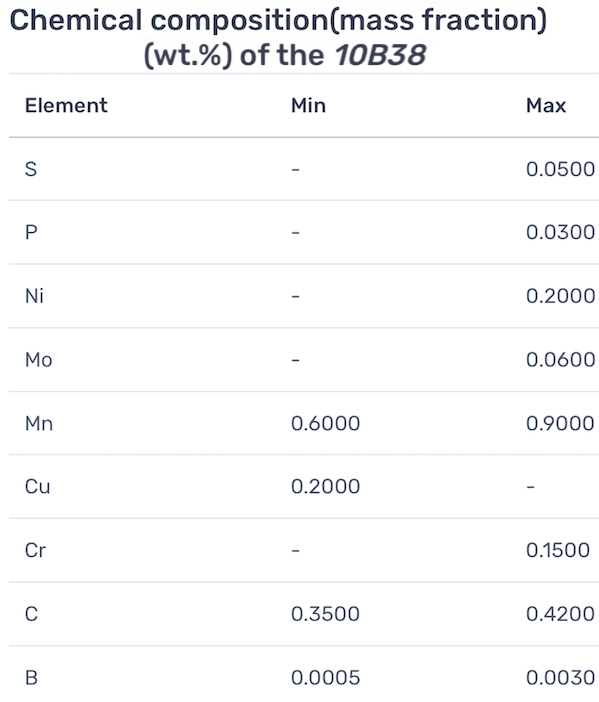

First off, the best place to post a question like this on metallurgy is the sci.engr.metallurgy newsgroup. There's a lot of traffic there, and a lot of experts on metallurgy. That said, I can tell you the composition of 10B38 is iron with 0.35-0.42 % carbon, 0.60-0.90 manganese. Standard limits on sulfur and phosphorus. The 'B' means that it has been boron treated, and can be expected to contain 0.0005-0.003 % boron, to improve hardenability. Not hardness, but hardenability: there's an important difference.

Tensile strength will depend on the heat treatment you give it, and can vary widely: 50 ksi and 130 ksi were both listed in one of my handbooks as typical numbers. Elastic modulus will be really close to 30 million, and density will be just about 0.283 pounds per cubic inch.

Matweb does have some information on 1038: surf over to www.matweb.com/SpecificMaterial.asp?bassnum=M1038B and group;=General and join me in laughing at the 5 significant figure accuracy for the Young's modulus. Hey, they try.

Hope this helps!

Lee Gearhart

metallurgist - E. Aurora, New York

2001

![]() Dear Lee

Dear Lee

Your clarification was quite helpful to me. I am due to purchase some hundred tons of 10B38 steel for cold forged bolt and nuts production.

Mehrdad Rostami

- Tehran, Iran

August 16, 2011

Q. I was wondering if any of you have any information to Austempering 10B38. I am especially interested in a TTT Diagram for this material.

Thanks,

Mower blades - Orangeburg, South Carolina

2005

ASTM A684 substituted for 10B38

Q. We are currently fabricating a small cutting blade out of 10B38 steel. Basically we purchase a larger blade (made of 10B38) then, using a plasma torch, cut the blade to the desired shape then sharpen. Well of course this is pricey. Our vendor can laser cut the part, but they have ASTM A684 spring steel. Obviously, I'm not worried about wearability of the A684. But we weld this part to a mounting bracket. Is the weldability of A684 comparable to the 10B38. I don't won't these things snapping off of the machine in the middle of the field. Any info would be greatly appreciated.

Matt SeuferlingDesigner Engineer - Hillsdale

February 28, 2011

A. There are a number of steel grades that meet the composition requirements of ASTM A684, including 1055, 1074, and 1095. All of these have higher Carbon content, and reduced weldability compared to 10B38. You should definitely determine the exact composition of the proposed steel, but most likely it will be one of these. Have you considered a different joining method, such as TIG brazing with a bronze filler wire?

Toby PadfieldAutomotive component & module supplier - Michigan, USA

March 2, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread