-----

Make a silver "Oscar" with silver nitrate

Q. Hello,

I have to do a project for my chemistry class involving the creation of a silver Oscar. Here are the specifications: The presentation to the Academy must include the cost of manufacturing the silver statuette of the same size and design as the current Oscar. I need a procedure for obtaining silver from silver nitrate. The current Oscar is 3.86 kg. How can I use this to determine the mass of silver needed to make the silver statuette of the same volume as the gold statue? I really need help. I also need to know the materials because I have to find the lowest cost possible.

Thank you!

Christine B [surname deleted for privacy by Editor]- Newtown, Pennsylvania, USA

2001

Q. Haha I'm doing the same project, and I have no clue what to do. Well, try going to chemical suppliers and finding stuff.

Good luck!

Ryan M [surname deleted for privacy by Editor]- Fond du Lac, Wisconsin, USA

2002

Q. Hey~

We are doing the same thing. We have started with using Zinc or copper in our equations to obtain silver. So far that is all we have done. Have any other ideas?

Kaci S [surname deleted for privacy by Editor]- Edmond, Oklahoma

2002

A. Hi students. People won't be able to help you if the assignment isn't clear; for that you need to go to your teacher for clarification. Certainly the current Oscars are not solid gold. 3.86 kg of gold at, say, $1200 an ounce would cost over $163,000. And if you don't know what they are made of, you can't figure out their volume from their weight, and therefore how much silver would be needed to make one. We can help you figure out the answers, but we can't help you figure out the question :-(

Still, if you're lost by the theory, and don't understand how you get silver from silver nitrate, please see the tutorial on letter 26613, "Extracting silver from silver nitrate solution for school project".

Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2014

A. To obtain silver in silver nitrate, you dip copper wire into a a test tube, add silver nitrate. In a few minutes long thin crystals will begin to form on the copper wire. After about 10 minutes gently shake the crystals off, and they will accumulate at the bottom of the tube. Wait another ten minutes and repeat until a fair amount has added up. Strain the crystals and let them dry. Put the dry crystals in a crucible. Put it right in the hottest part of the bunsen burner. Silver has to heat to about 1200° to become malleable. Let the silver melt together, quickly drop the silver droplet into lukewarm water. Then my friend you are the proud owners of pure silver... maybe you should all chrome your teeth and be all gangsta when you present your pure solid silver awards out ... that's what's good ... good luck, Jim.

James D [surname deleted for privacy by Editor]- South River New Jersey, U.S.A.

2004

Sorry, but I don't think James is correct that crystals will form. I think the copper wire will simply acquire a thin coating of silver metal.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2014

Q. We're doing that project too -- man it bites. Sorry, but we don't know what to use either. Good luck!

Kristen C [surname deleted for privacy by Editor]- Rochester, New Hampshire, US

2004

Q. James, you were very helpful, but what do you use to filter the crystals? Even a coffee filter's pores are too large. So that's my dilemma. HELP!

Tyler W [surname deleted for privacy by Editor]- Caldwell, Idaho, USA

2007

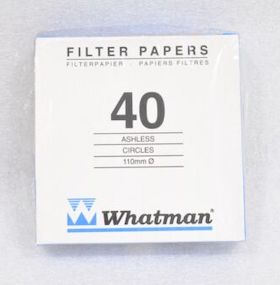

A. Tyler, your lab teacher can give you paper filters, often called "Whatman filters", which look a lot like coffee filters but are available in various pore sizes.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

2005

Q. I am a high school sophomore and a chemistry student and I am working on a project which has the following description:

The Academy of Motion Picture Arts and Sciences has announced plans to award a second place Oscar for each category. They are currently searching for a company to produce these statuettes which will be identical to the current Oscars (mass = 3.86 kg), but will be made of solid silver instead of gold. The silver for the statuettes will be produced from AgNO3 reacting with some other metal in a single replacement reaction.

Teams will have to consider:

a) the best metal to use including cost, quantities, and safety

b) mass in grams of silver needed

c) mass in grams of AgNO3 needed; include safety and cost

d) reaction to be used to produce the silver. Metal activity series must be considered as well as cost effectiveness of different reactions and safety.

e) stoichiometry involved

f) cost of reactant materials (be sure to note package size) as well as what chemical supply vendor to use. Remember you are making 200 solid silver statuettes.

g) safety and disposal of all byproducts of your reaction

I am not sure which metal to use, but I am considering zinc, copper, iron, magnesium, and tin. All of those metals are more reactive than silver, so any of the five would work in the reaction, but I need to choose which one will be the safest (most important) and most cost efficient. I would appreciate if someone who knows how to do this would please help me decide which metal would be the best. Thank you.

Lauren F. [surname deleted for privacy by Editor]student - Buffalo Grove, Illinois, USA

2005

A. Hi Lauren,

The Oscar isn't pure gold. It is gold plated over a cast, polished alloy of something (can't remember but I think it was a type of pewter). There is a company in Chicago that makes these (I was there a month ago, kinda cool I have to say), and they have a lock on the design. If anyone is making a silver Oscar, I imagine it is them.

Look up decorative silver plating processes and that should give you some idea of average plating thicknesses and the chemicals used. Going to be a hard time calculating surface area, but I bet a good estimate would do and you can go from there for your calculations.

Hope that helps a bit. Sounds like your teacher has some good ideas.

If you just want to get silver from silver nitrate, copper is the ticket:

Cu(s) + 2AgNO3(aq) -> 2Ag(s) + Cu(NO3)2(aq)

or something like that

Trent Kaufman

electroplater - Galva, Illinois

A. A really neat hypothetical question! The crux of the problem is how much silver do you need, so you need to calculate the volume occupied by the current gold Oscar that weighs 3.86 Kg. Then convert that volume to a weight in silver;then calculate how much silver nitrate contains the required amount of silver. You then have to extract the silver from the salt and you do this by exchanging the silver for another metal. You need to work out what weight of (say) iron is equivalent to the required weight of silver. Remember that to reduce silver nitrate to silver, you only need 1 electron, but if you (say) oxidise iron to Fe(III), it will give you three electrons. This will affect the amount of metal you need to get your silver. Your choice of metal will also be influenced by the reactivity of it and its cost. Of course, once you have recovered your silver, you will be left with the nitrate salt of the metal you use as a reducing agent. Try to find a market for that salt instead of treating it as waste, then you can sell it as opposed to having to pay to get it disposed of. I now think you and your team can sort the rest out for yourselves.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

2005

Q. I'm a student. For a particular class of mine we have to recreate the Academy Awards. In doing this we have to be able to explain how much an Oscar would cost to be made, and what is it actually made of. I saw that other students needed to know how to recreate the Oscar using a different metal, but I need to start from the beginning. I need to know WHAT is the original Oscar statue made of? Most importantly where would I go to have one (or 25 for my situation) created at? Thanks.

Lamesha H. [surname deleted for privacy by Editor]student - Durham, North Carolina

2005

A. Hi Lamesha. See http://www.rsowens.com/news/article.asp?ARTICLE_ID=136&

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2014

Q. I'm a senior in high school in Eugene, Oregon. I am in a chemistry class and we have to do a project in which we make a "silver Oscar." I was wondering if you had any suggestions on how to find the mass of silver nitrate needed to obtain silver for the oscar. Also, a reaction that can be used to obtain silver from the silver nitrate. A lab is also required to show how you got silver for the oscar. THANK YOU

Jane L. [surname deleted for privacy by Editor]high school - Eugene, Oregon, USA

2005

A. Jane L, I think the answer you want is already in this thread.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

2005

A. Lauren, et al,

The company that makes the Oscar now is R. S. Owens & Co., a trophy manufacturer located on the north side of Chicago. They have made the statue since 1982.

The metals used in the manufacturing of the piece, I believe, are zinc, lead, and copper. I'm not sure of the ratio of each. After it is pulled from the mold and has gone through several secondary operations, it is gold electroplated. It is 13 1/2" tall and weighs 8 1/2 lbs. [Ed. note: 8 1/2 pounds equals 3.86 kg]. The cost to the Academy is right around $100.00 each.

I know a bit about the Oscar as I worked as a Sales rep for the company that made the Oscar originally, Dodge Trophies, also a Chicago company. They were made originally in Dodge's Los Angeles plant and after it closed, the statues were made at their plant in Crystal Lake, IL (also closed). Dodge had been out of business since the early 1980's. R. S. Owens bought the molds in 1982 and have made them ever since.

Maybe this info helps with your project.

Good luck.

- So. Holland, Illinois, USA

![]() Thanks very much, Bill!

Thanks very much, Bill!

Students, here's the making of the Oscars --

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2014

April 7, 2014

I'm doing a project for school and am trying to find the least expensive method of producing a silver oscar that is identical in volume to the current gold oscar.

Amount (mass) if silver needed to make a silver statuette of the same size(volume) as the current statuette

Mass of silver nitrate needed to obtain silver from the silver nitrate

Cost of materials needed to make statuette (silver nitrate and any other metals needed to obtain elemental silver)

Helpful info:

The current gold statue is 3.86 kg.

use the most cost effective way to obtain silver from silver nitrate.

- Waverly, Missouri USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread