-----

Anodizing titanium to blue color

Q. I have a pair of blue titanium eyeglasses frames that I love, but couldn't find a replacement for, so I bought nearly the identical frames that are silver (non-anodized?) titanium. It was my plan to anodize them with a few 9v batteries to blue.

So I collected materials, mostly from the local dollar store: a stainless dog bowl, a plastic spaghetti strainer (with the handle removed, that fits inside the dog bowl), alligator clips, batteries, and a short piece of titanium wire.

Scrubbed the frames in detergent with Scotch Brite pad, filled the dog bowl with distilled water with borax (later baking soda), negative battery clip to the bowl, positive to the wire attached to the frames in the plastic spaghetti strainer.

I get bubbles. No color. Check for something touching...no shorts. Nothing.

Did I do something wrong? Titanium eyeglass frames (Moda, not necessarily cheap) aren't really that much titanium? The dog bowl is wrong? The solution is wrong? Can anyone help?

- Weslaco Texas

September 16, 2021

A. Try trisodium phosphate ⇦ on eBay or Amazon [affil link] solution as electrolyte ( 30 gms/lit.water/30 volts = blue colour) and piece of stainless steel as cathode( but SS dog bowl must be OK too). Maybe your frames are clearcoated, try to clean them with acetone ⇦ on eBay or Amazon [affil link] Flammable! . Hope it helps and good luck!

Goran Budija- Cerovski vrh 157 Croatia

September 29, 2021

⇩ Related postings, oldest first ⇩

Q. Does anyone know about a blue coating used on titanium?

I have seen it applied on bolts that were to be used in the aerospace industry - supposedly they were for satellites. I don't think the coating was anodized (ti oxide).

I asked a friend who used to work in aerospace if he had seen the coating. He remembered a blue coating on titanium and thought that it was from some other coating process that usually wasn't used for titanium. He didn't really know any specifics however, just that it was blue and intended for something else.

Any ideas on what it could be? Or if it is Ti Oxide, what would be the purpose of anodizing the bolts blue? Visibility? Electrical insulation?

Marc Pfister- Sunnyvale, California USA

2001

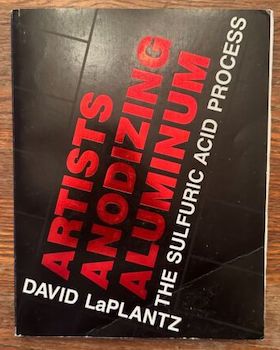

The Sulfuric Acid Process"

by David LaPlantz

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Warren. I wasn't even aware that there was an AMS 2488 "Type 3" anodize; I thought Tiodize called Type 2 anodizing from which the powdery fuzz is sandblasted away their "Type 3". And I think some artists call thin color anodizing "Type 3". But if my knowledge of AMS 2488 is dated, or I'm confused, I'd appreciate clarification from someone regarding what AMS-2488 Type 3 is supposed to be.

It doesn't surprise me that titanium left to anodize for hours would turn gray and powdery as that is the normal color and condition of the heavier coatings. The colors of color anodizing are from interference between light bouncing off the surface of the parts and off the surface of the coating, so the coatings are usually only a partial wavelength thick, although I understand you can also go one wavelength plus a partial wavelength for thicker and more durable coatings. I do suspect the limited ampacity of your power supply to be a problem.

Again if there are specs for Type 3 coatings I'd like to know what spec covers them. Thanks.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2014

A. Anodizing in sulfuric acid - type III - creates a thin gray layer, that is not as durable as alkali type, but suitable enough for some applications where a one-turn screw action is required.

Color anodizing (Type IV if I am not mistaken) can be done in various solutions (even in Coca-Cola), however only in low voltages. When going to higher voltages we suggest switching to Sodium Wolframate or Oxalic acid for cleaner colors. Also surface preparation is a must, otherwise the coloring process will be spoiled (you will see gassing) and fall into gray due to iron surface contamination.

Anna Berkovich

Russamer Lab - Pittsburgh, Pennsylvania

(ed. update July, 2025: sorry, Anna has retired)

March 2, 2014

Q, A, or Comment on THIS thread -or- Start a NEW Thread