-----

Chromium stripping

I am by first time working in a hard chrome shop; where defective chromium is stripped with hydrochloric acid 10-20%, without inhibitors. I've learned from ASTM B630 a different method: anodic treatment in a caustic solution. Could this treatment be done with the same reversible rack for hard chrome plating, and the same conforming lead anodes, but submerging in the caustic solution? Could any kind person explain me how to do anodic treatment in a caustic solution?.

Douglas Arias- Costa Rica

2000

Douglas, A good caustic solution to test strip decorative chrome is a electrocleaner usually works pretty good The only Draw back to stripping in a caustic solution is that the process passivates the nickel surface in which you a nickel strike or good activating process to get Chrome to stick I would not use lead anodes to strip chrome in the caustic solution. If it is ID your are striping you could use a steel cathode you probably would not need conforming anodes for stripping of old work

Chris Snyderplater - Charlotte, North Carolina

2000

I suggest stainless steel anodes for your cathodes. These are readily available and do not dissolve in the caustic.

Make the work piece anodic by connecting it to the positive terminal on the rectifier. The stainless steel cathodes should be connected to the negative terminal.

We heat our solution to 125 F to speed up the process.

A 10% sodium hydroxide

[affil link] solution works well but there are less corrosive proprietary solutions that work just as well.

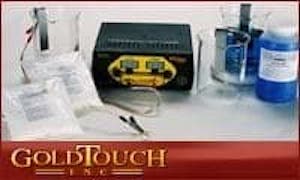

Gold Touch Inc.

Cleveland, Ohio

2000

You may get problems by stripping a chrome plated stainless steel in a caustic solution using current. Sometimes you get an electropolishing effect on stainless steel, i.e. you strip your base material. (example: I experienced this effect when I stripped steel parts on a stainless steel rack. The rack was damaged.)

If you want to use a caustic solution using current for stripping you need: a steel tank (without coating) The tank is the cathode. a rectifier which supplies at least 6 V electrolyte: 100 g/l NaOH

Switzerland

2000

Mr Hekli has the right idea, if the parts are stainless, strip them in muriatic acid

⇦ on

eBay or

Amazon [affil link]

50/50 with water at room temperature.

However, if the substrate is mild steel or tool steel, they can be effectively stripped in a caustic bath of about 20-30% sodium hydroxide and water. Temperature can be ambient to 120 °F.

Use a mild steel tank or drum connected to the negative source and connect the parts to the positive side.

Use approx. 1.5 - 2 amps per sq. inch for best results.

Be very careful of the hydrogen gas generation while the stripping process takes place - do not connect or disconnect the rack or parts before shutting down the power source as a spark can ignite the hydrogen gas. Ventilation is very important.

- Cleveland, Ohio USA

2001

Q, A, or Comment on THIS thread -or- Start a NEW Thread