-----

Nickel-boron plating pitting problem in MEMS probe card

Q. Hello I am Kim.

I am currently working as a plating engineer in a manufacturer of probe cards based on MEMS (micro electro-mechanical systems) manufacturing technology.

I'm looking for guidance on an intermittent pitting defect that has appeared in our acid nickel-boron (Ni-B) electroplating line.

• Process parameters

- Bath pH : 3.9 (spec 3.9-4.1)

- Temperature: 45-50 °C

- Current density : 2.0 ASD (0.50 A)

• Defect description

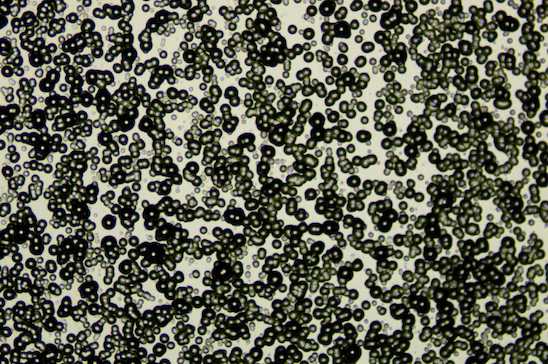

- Circular pits across the surface (see photos).

- Defect appears on some lots, not all.

- A completely new bath showed the same issue <2 months after make-up.

• Troubleshooting done so far

1. Re-made the bath - pits returned.

2. pH, boron content, and temperature within spec.

3. Adding the Ni-B wetting/leveling additive reduces, but does not eliminate, the defect.

• Questions

1. Which additional checks would you recommend (Hull-cell, surface-tension, CVS, etc.)?

2. Could marginal wetting-agent depletion, combined with current crowding, explain the lot-to-lot behaviour?

3. Would lowering the current density or using pulse/pulse-reverse plating be an effective fix?

Any insights or similar experiences would be greatly appreciated.

Thank you in advance!

Kim

- Korea

July 30, 2025

Q, A, or Comment on THIS thread -or- Start a NEW Thread